Multi-suction-nozzle device

A multi-suction nozzle and solenoid valve technology, which is applied to workpiece clamping devices, suction cups, connecting components, etc., can solve problems such as increased cost, decreased attractiveness, and air leakage from suction nozzles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

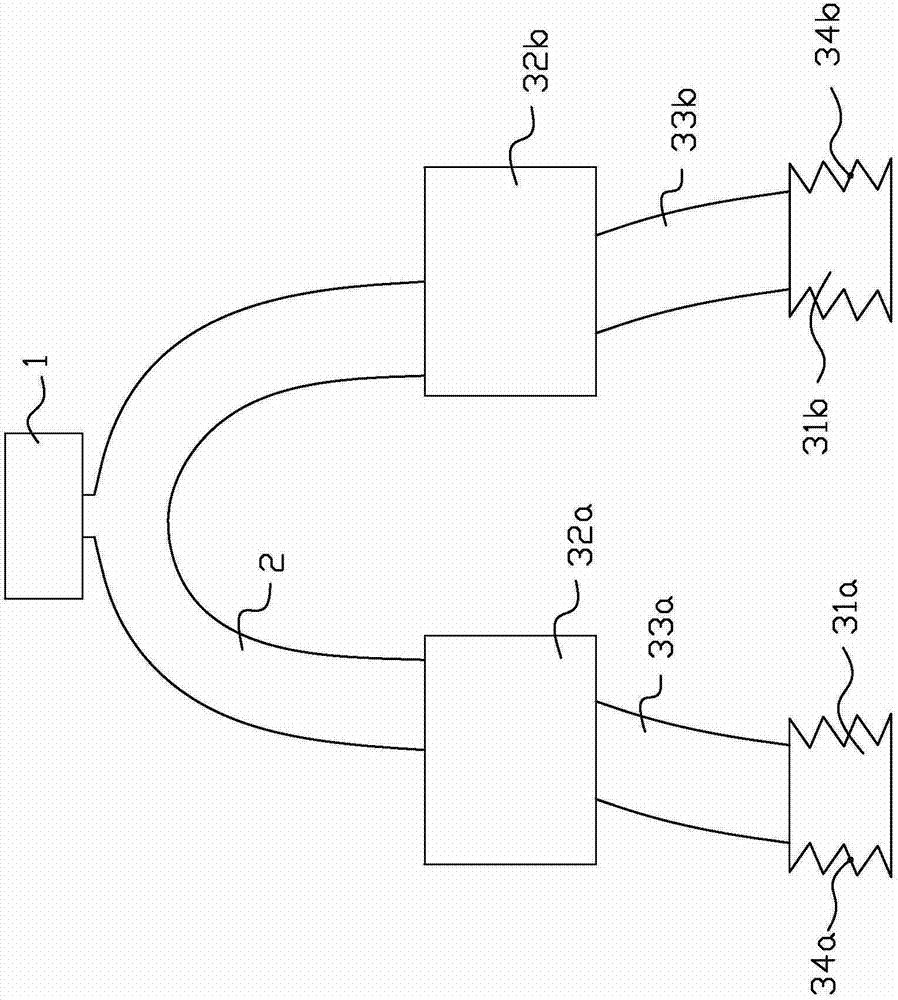

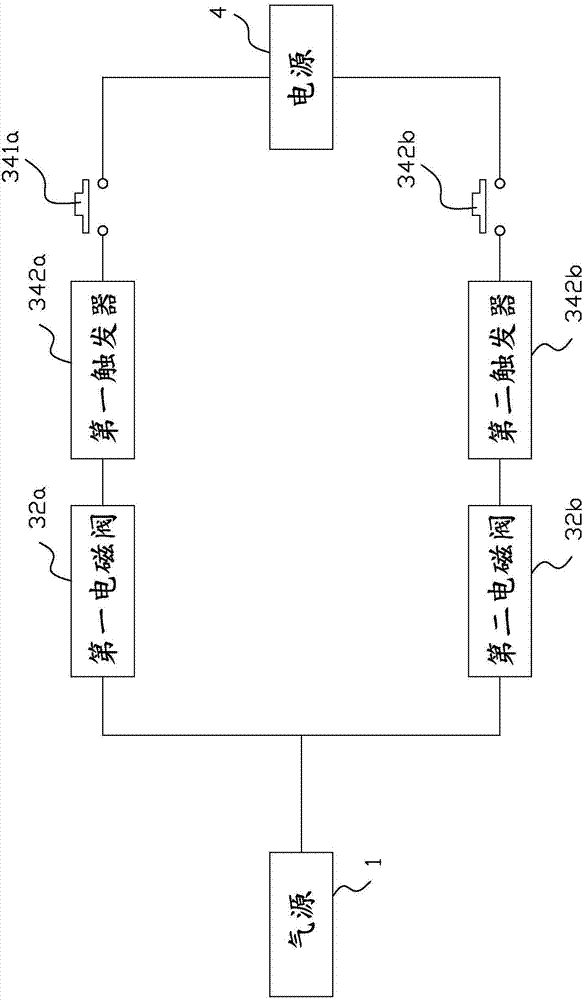

[0010] see figure 1 , figure 2 As shown, a multi-nozzle device of the present invention includes n nozzle units, an air source 1, a nozzle pipeline 2 and a power supply 4, wherein n is equal to or greater than 2, and in this embodiment, n is equal to 2, namely The nozzle unit includes a first nozzle unit and a second nozzle unit, wherein the first nozzle unit includes a first nozzle 31a, a first solenoid valve 32a, a first hose 33a, a first switch element 34a; The two-nozzle unit includes a second suction nozzle 31b, a second solenoid valve 32b, a second hose 33b, and a second switch element 34b.

[0011] The first solenoid valve 32a is connected to the air source 1 through the suction nozzle pipeline 2, the first suction nozzle 31a is connected to the first solenoid valve 32a through the first hose 33a, and the first switching element 34a includes a first A tact switch 341a and a first trigger 342a, wherein the first tact switch 341a is set on the upper corrugation or the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com