Method for calculating running electrical equipment partial discharge quantity through SF6 decomposition product content

A technology of partial discharge and decomposition products, applied in the direction of testing dielectric strength, etc., can solve the problem of inability to measure partial discharge of electrical equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

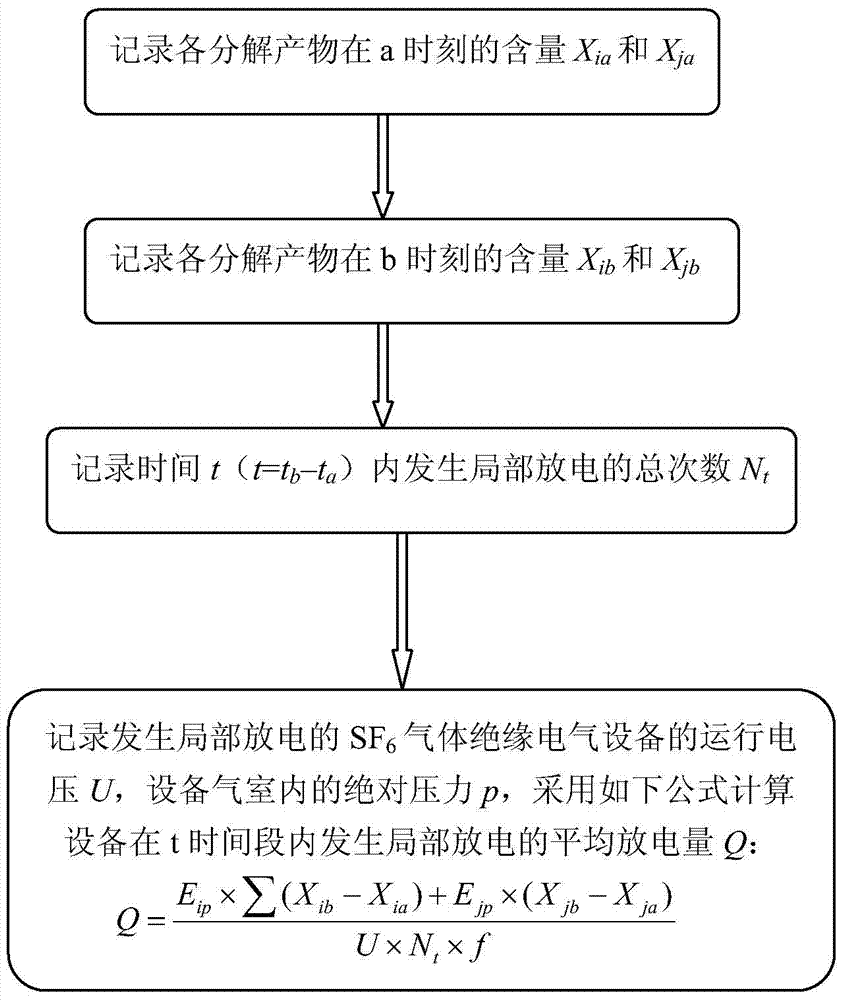

Method used

Image

Examples

Embodiment 1

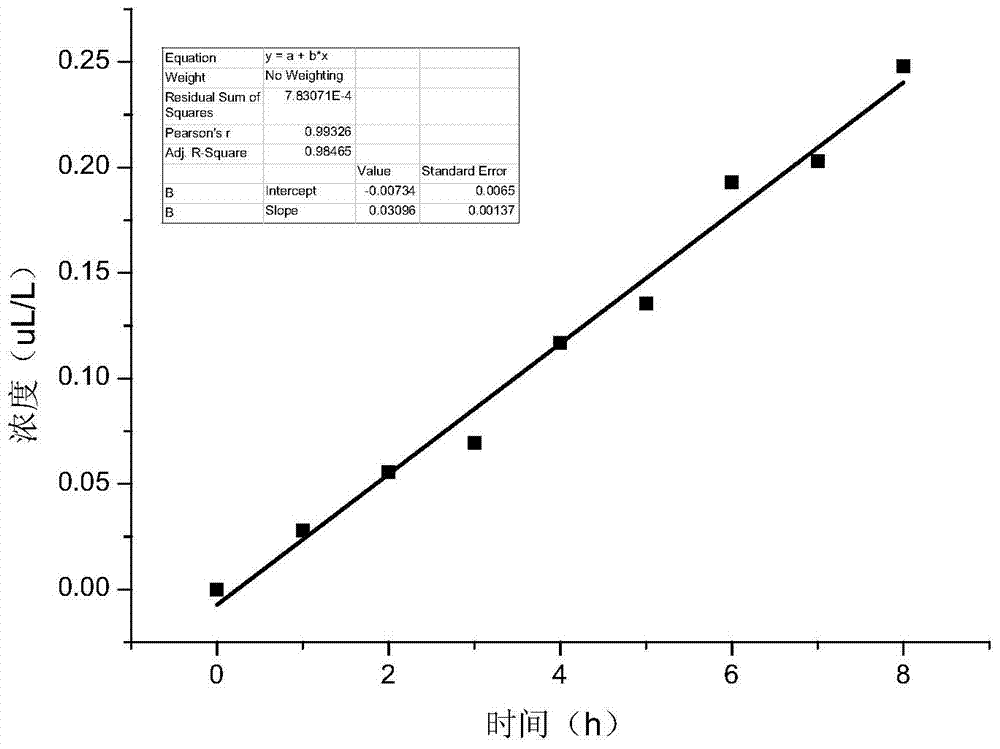

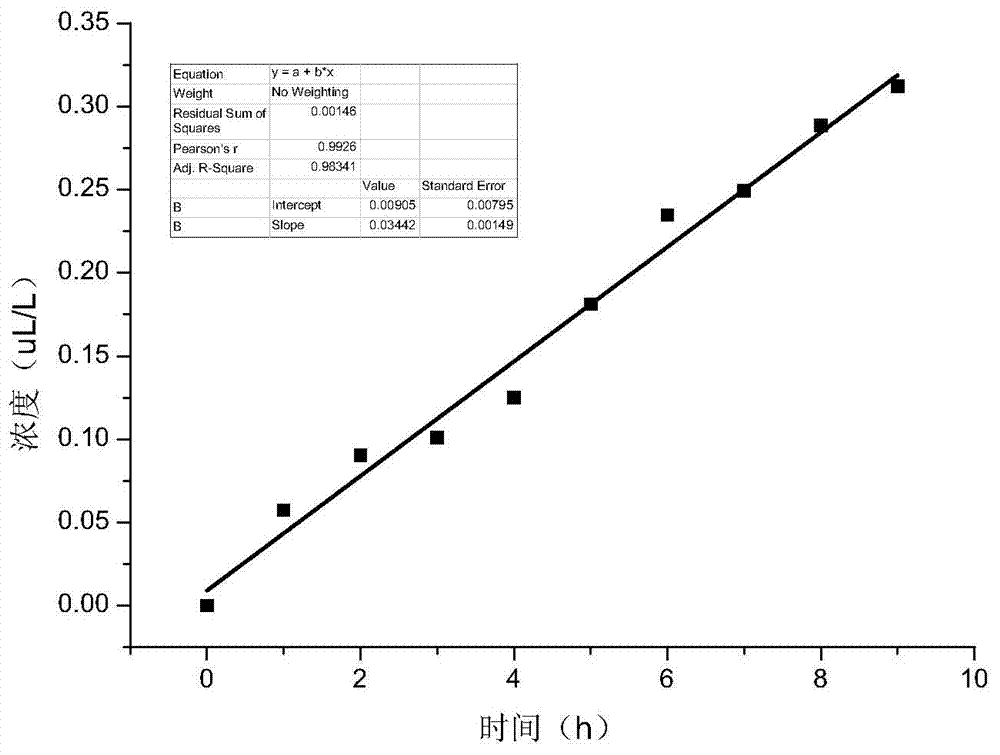

[0081] A suspected faulty 220kV voltage level GIS main air chamber, the absolute pressure of the air chamber is 6MPa, and the volume of the air chamber is 100L. The PD electrification detects continuous PD signals, and the average discharge times per hour is obtained through continuous monitoring by the UHF PD detector. About 2×10 9 times, only SOF was detected in the detection of SF6 gas decomposition products 2 and SO 2 , obtained by continuous monitoring of SOF 2 and SO 2 The hourly increment is about 0.1μL / L, and the moisture detection does not exceed the standard.

[0082] According to the formula:

[0083] Q = E ip × Σ ( X ib - X ia ) + ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com