An organic light emitting diode display with a touch panel

A technology of light-emitting diodes and touch panels, applied in instruments, semiconductor devices, electric solid-state devices, etc., can solve problems such as input errors and waste of light energy, and achieve the effect of reducing failures, reducing impacts, and realizing self-charging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

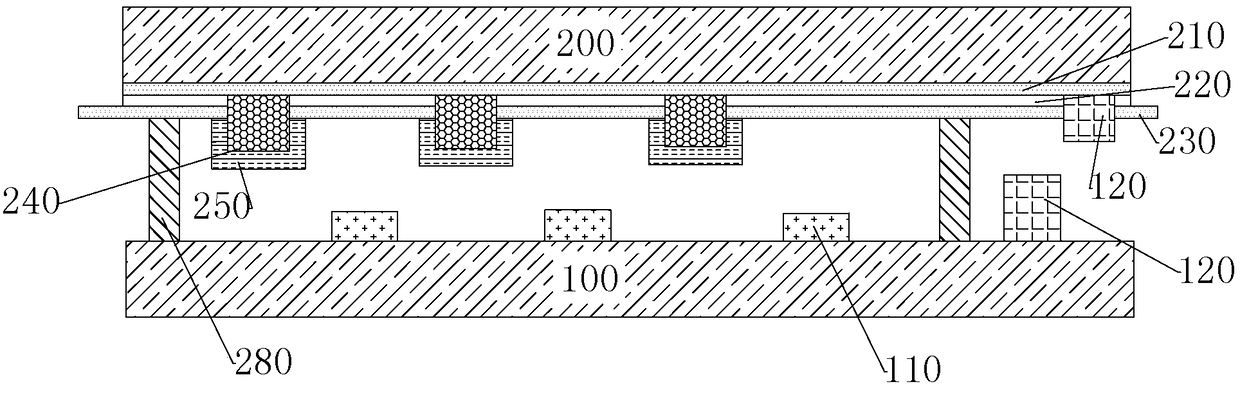

[0028] combine figure 1 As shown, it is a cross-sectional view of an organic light emitting diode display with a touch panel in this embodiment. The organic light emitting diode display with touch panel of the present embodiment includes:

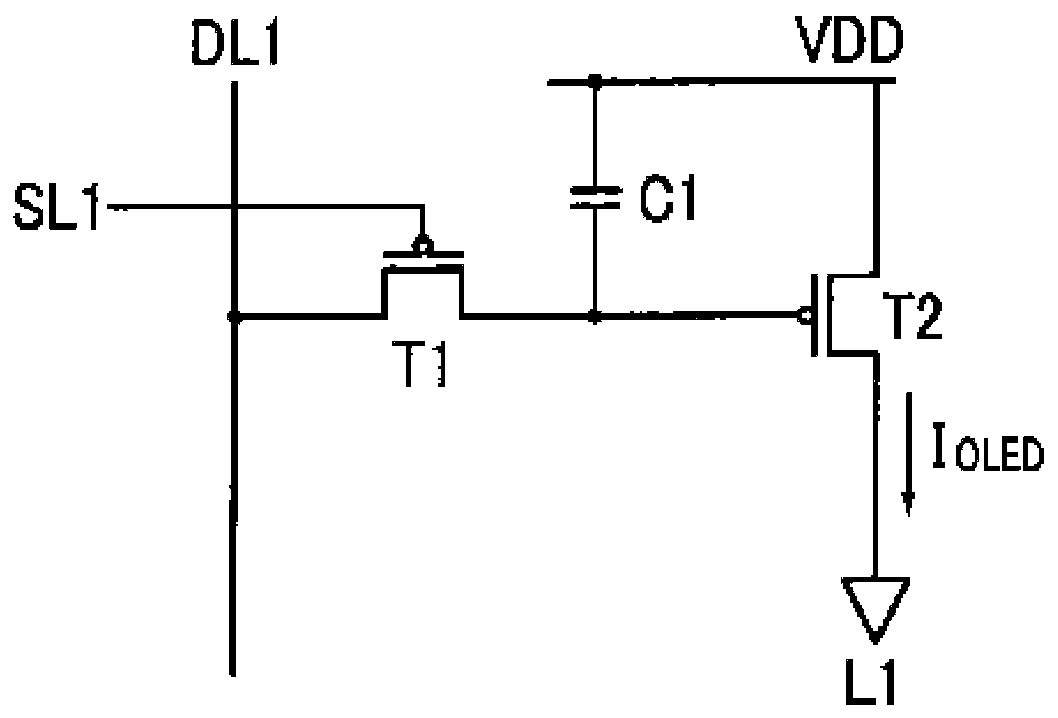

[0029] The first substrate 100, a plurality of organic light emitting diode pixel units 110 provided in the display area of the first substrate 100, combined (attached or connected) with the first substrate 100 through the sealing unit 280 (which may be a bonding agent, etc.) The second substrate 200, the touch electrode 210 formed on the second substrate 200 (the side facing the first substrate 100), the transparent insulating layer 220 formed on the touch electrode 210, the conductive layer 230 formed on the transparent insulating layer 220 , a plurality of photosensors 240 and a plurality of photovoltaic material layers 250 . The corresponding positions of the transparent insulating layer 220 and the conductive layer 230 are formed w...

Embodiment 2

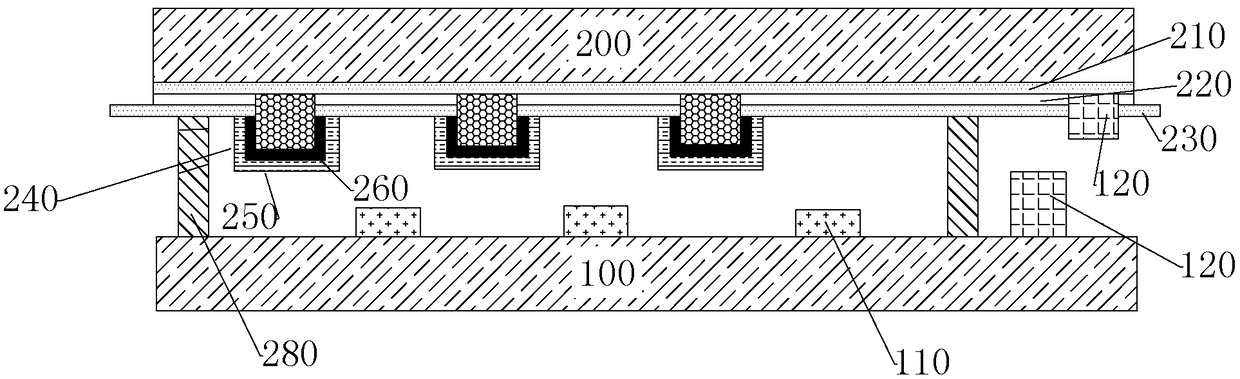

[0045] Such as figure 2 As shown, it is a cross-sectional view of an OLED display with a touch panel in this embodiment. This embodiment is basically the same as Embodiment 1, the difference being that the organic light emitting diode display with a touch panel of this embodiment is further provided with a reflective layer 260 between the photovoltaic material layer 250 and the light sensor 240 .

[0046] Specifically, combined with figure 2 , the organic light emitting diode display with touch panel of this embodiment includes:

[0047] the first substrate 100;

[0048] OLED pixel unit 110, located on the first substrate 100;

[0049] a second substrate 200, which is connected to the first substrate 100 through a sealing unit 280;

[0050] The touch electrode 210 is located on the second substrate 200;

[0051] a transparent insulating layer 220 formed on the touch electrode 210;

[0052] The conductive layer 230 is formed on the transparent insulating layer 210, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com