Hydraulic cylinder, in particular for a clutch actuating device in a motor vehicle

A technology of motor vehicles, hydraulic cylinders, applied in the field of hydraulic cylinders

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

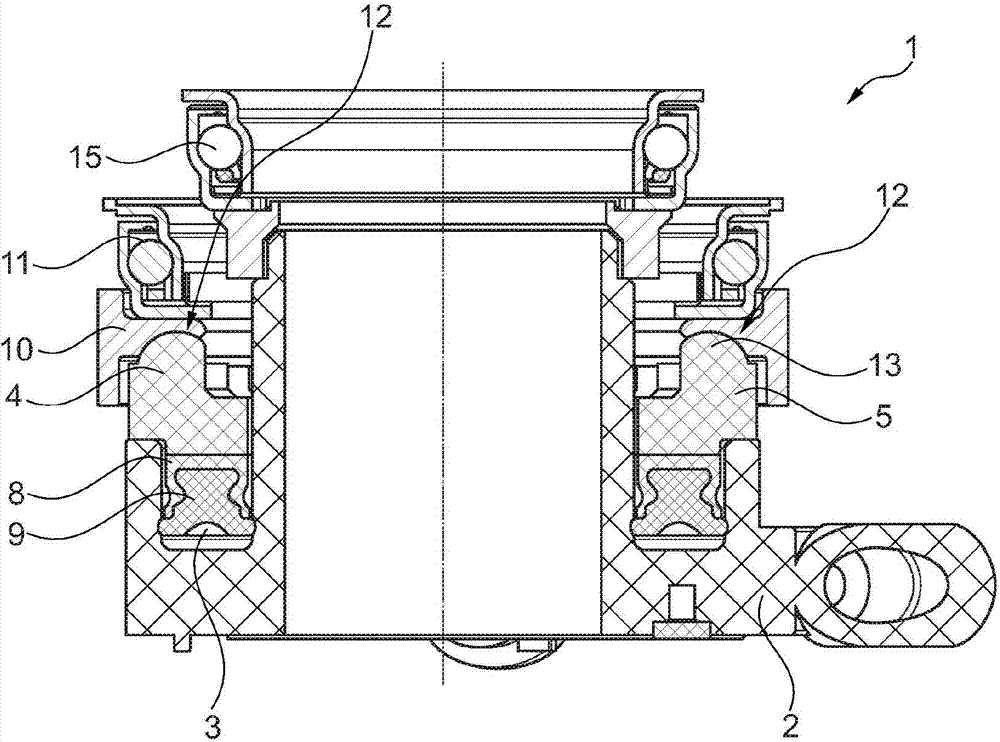

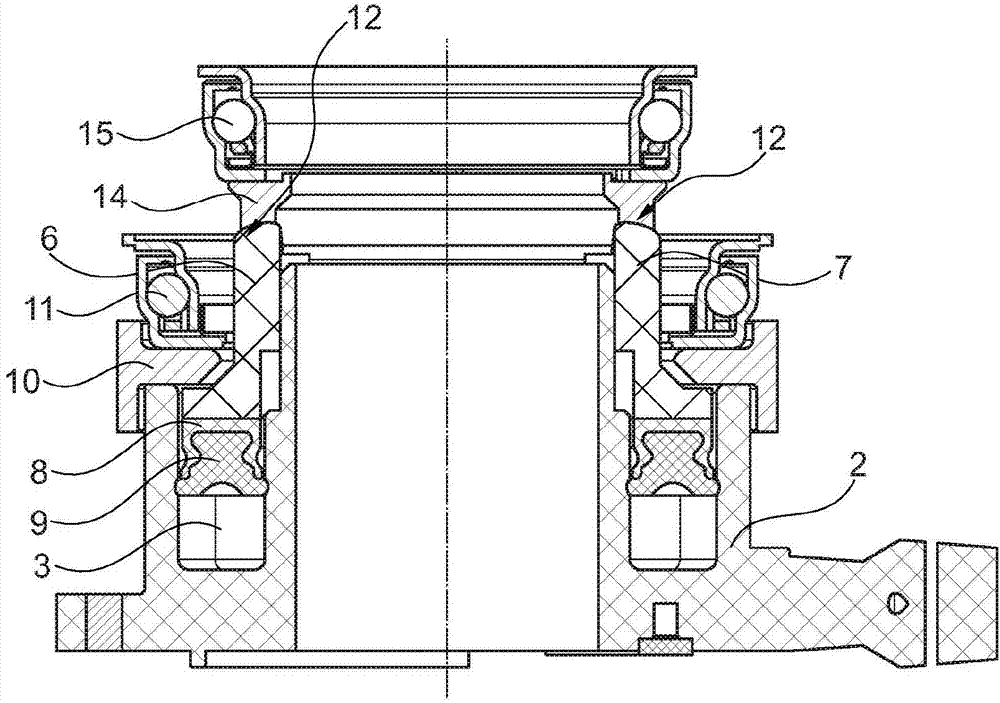

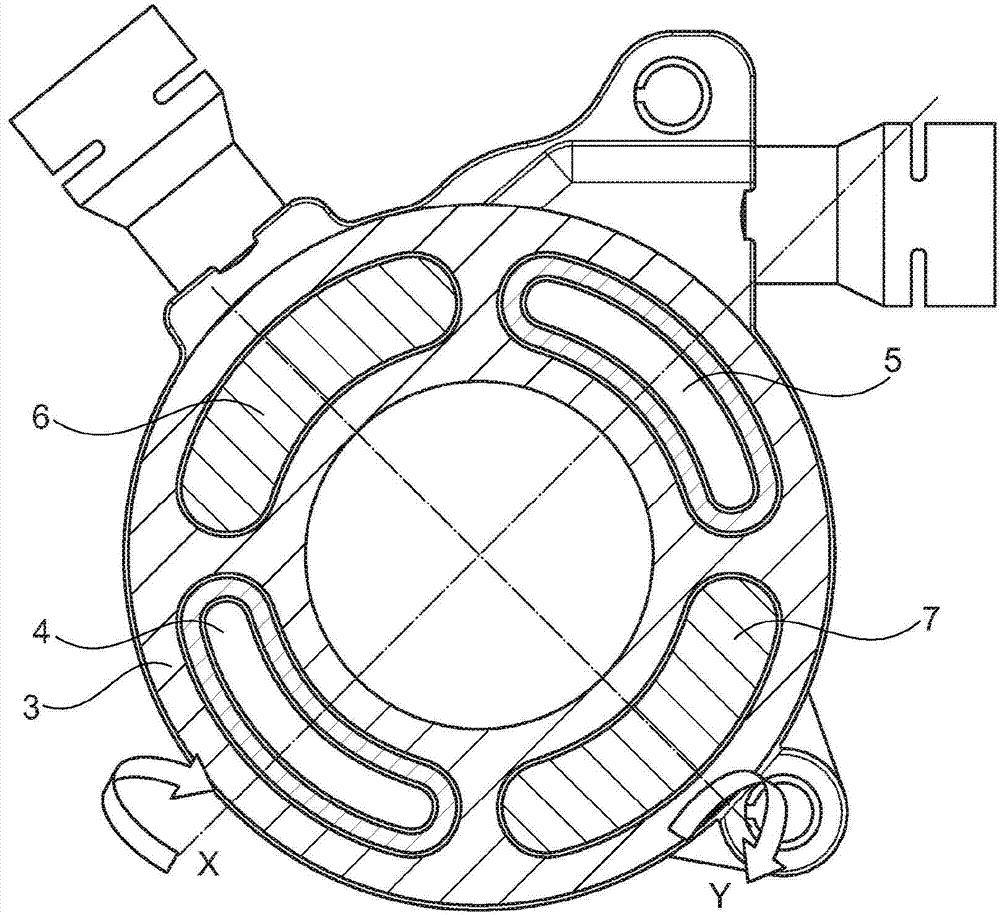

[0020] figure 1 A hydraulic cylinder 1 is shown, which is used as a slave cylinder in a clutch actuating device of a motor vehicle and is used here in particular for operating a double clutch. The hydraulic cylinder 1 consists of a housing 2, in which an annularly formed pressure chamber 3 extends, and four kidney-shaped pistons 4, 5, 6, 7 ( image 3 ) are mounted in the pressure chamber independently of each other in a movable manner. In this case, each piston 4 , 5 , 6 , 7 has a seal carrier 8 in the direction of the pressure chamber 3 , on which a seal 9 is arranged. The housing 2 surrounds a transmission shaft, not shown further.

[0021] Connected to the opposite pistons 4 and 5 is a first bearing ring 10 on which a first release bearing 11 is fixedly positioned. Release bearing 11 is connected to a first clutch, not further shown. The bearing ring 10 here has a circumferential recess 12 in which the ends of the respective pistons 4 and 5 are accommodated. The ends o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com