Double-layer door and window welding head and method for realizing automatic conversion between seam and seamless welding

A technology of seamless welding and automatic conversion, applied in the field of welding head, can solve the problem that the head of double-layer plastic door and window welding machine cannot realize automatic conversion between seam welding and seamless welding machine.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention is described in detail below in conjunction with accompanying drawing:

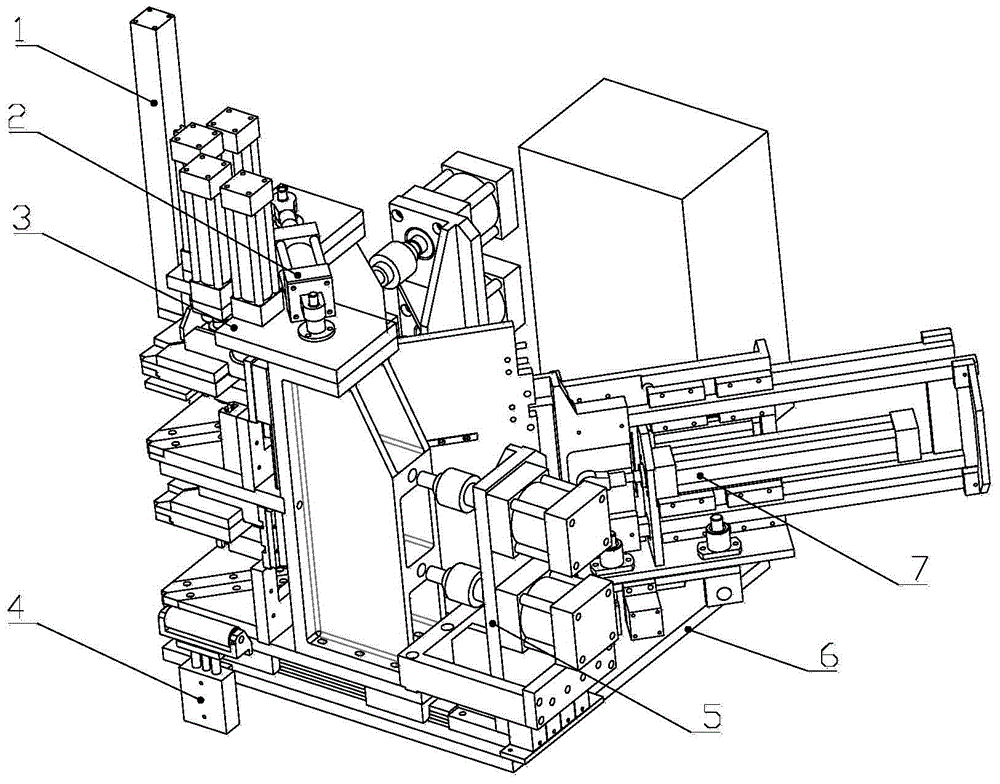

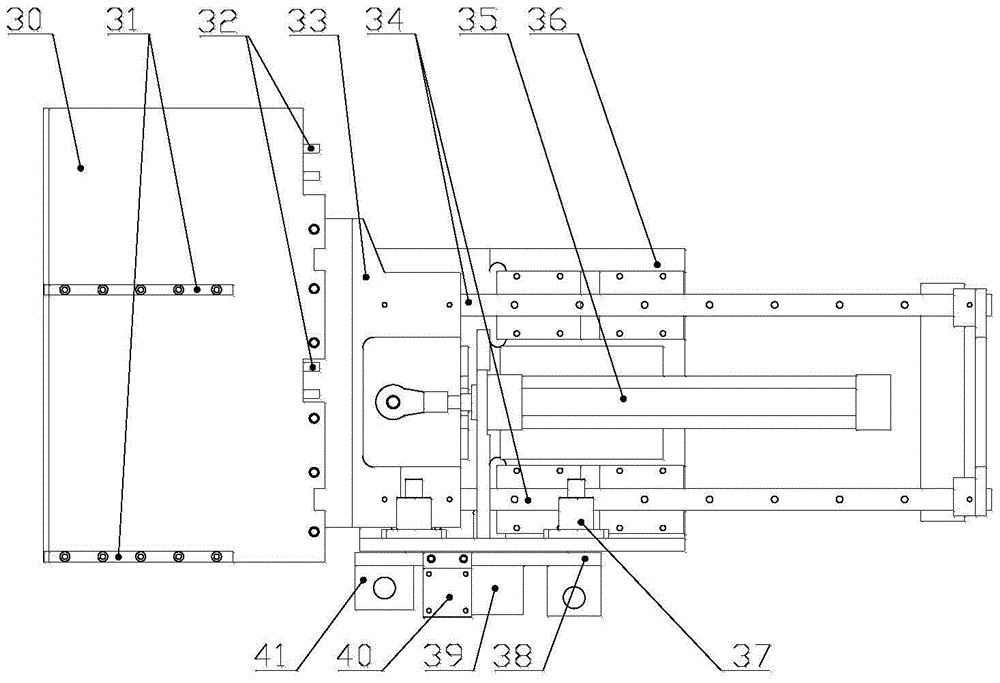

[0036] A double-layer door and window welding head that realizes automatic conversion between seam and seamless welding, including the head base 6 and the pushing and lifting mechanism 1, the upper tensioning mechanism 2, and the pressing mechanism 3 arranged above the head base 6 , the lower supporting mechanism 4, the working structure 5, the heating structure and the positioning structure 7;

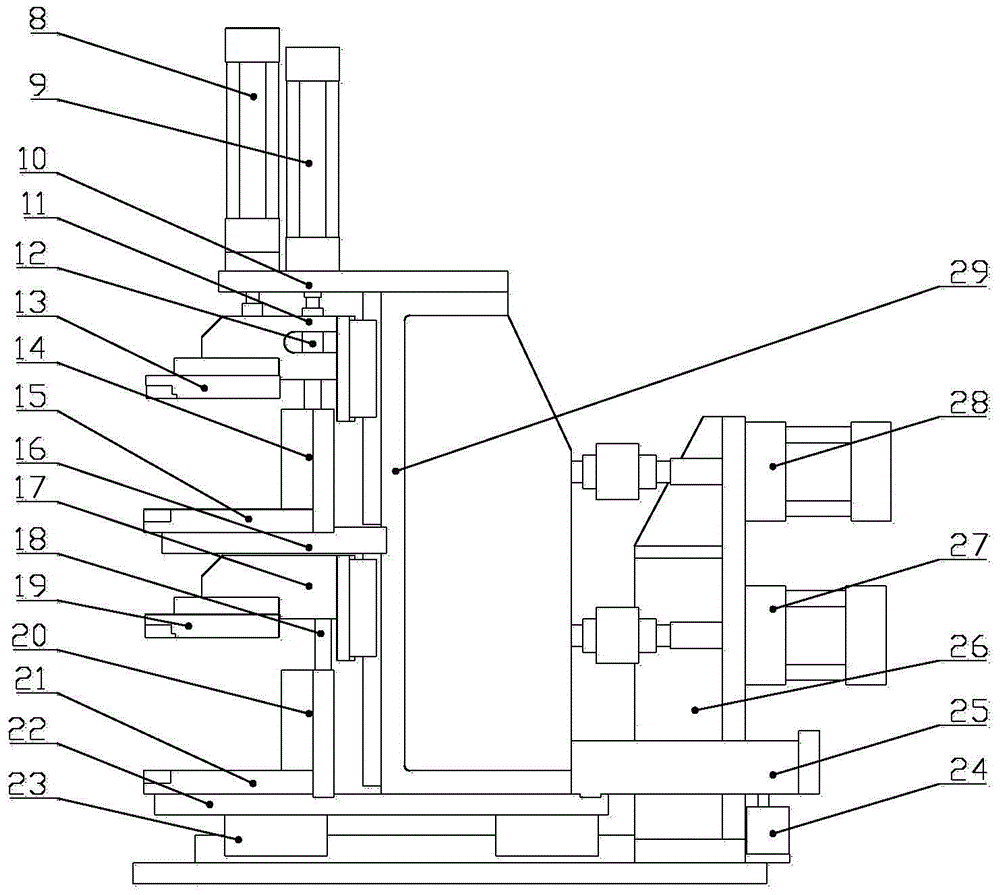

[0037] The pressing mechanism 3 is installed on the motion pair 23 of the linear slide rail, and includes two pairs of pressing pincers arranged up and down. Under the driving of respective air cylinders, slide up and down along the upper layer press clamp holder 29, and the lower press clamps of every pair of press clamps are fixed below the respective upper press clamps.

[0038] The side of the upper clamp seat is provided with two sets of linear slide rail kinematic pairs on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com