Double-layer door and window welding machine tool and method for realizing automatic conversion between seam and seamless welding

A technology of seamless welding and automatic conversion, which is applied in the field of welding machine tools, and can solve the problems that the head of double-layer plastic door and window welding machine cannot realize the automatic conversion between seam welding and seamless welding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention is described in detail below in conjunction with accompanying drawing:

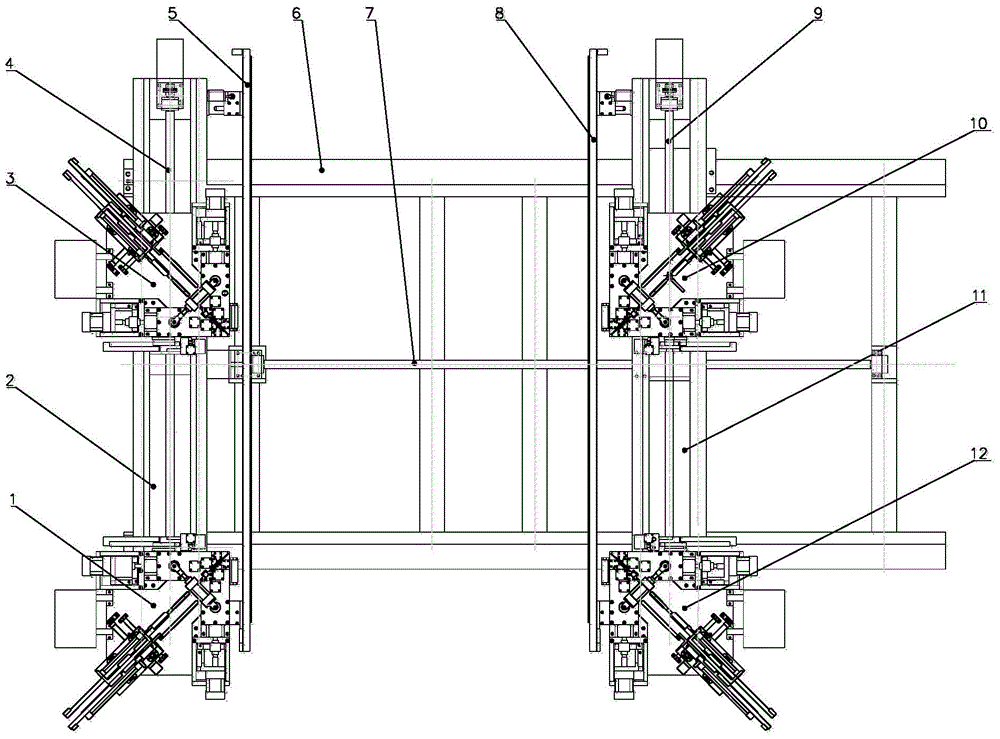

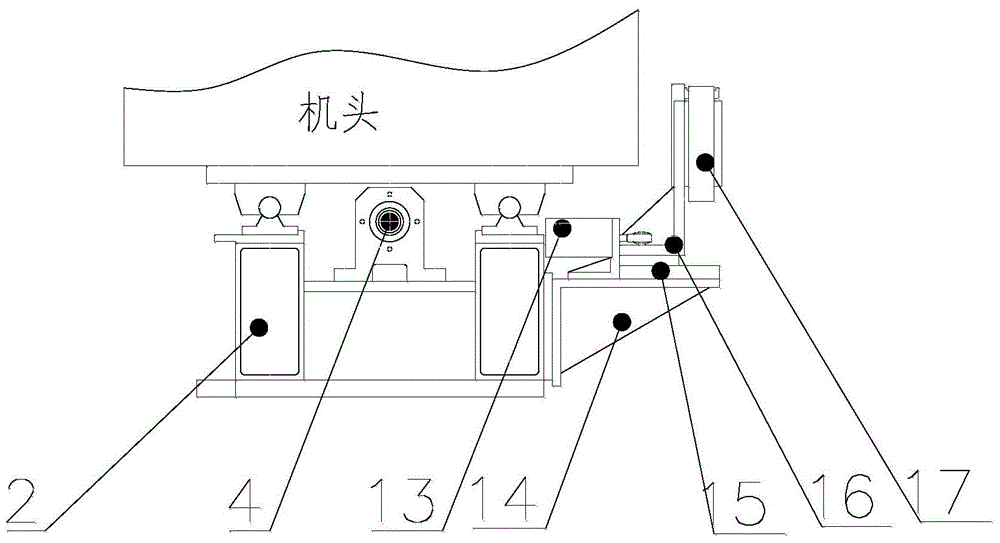

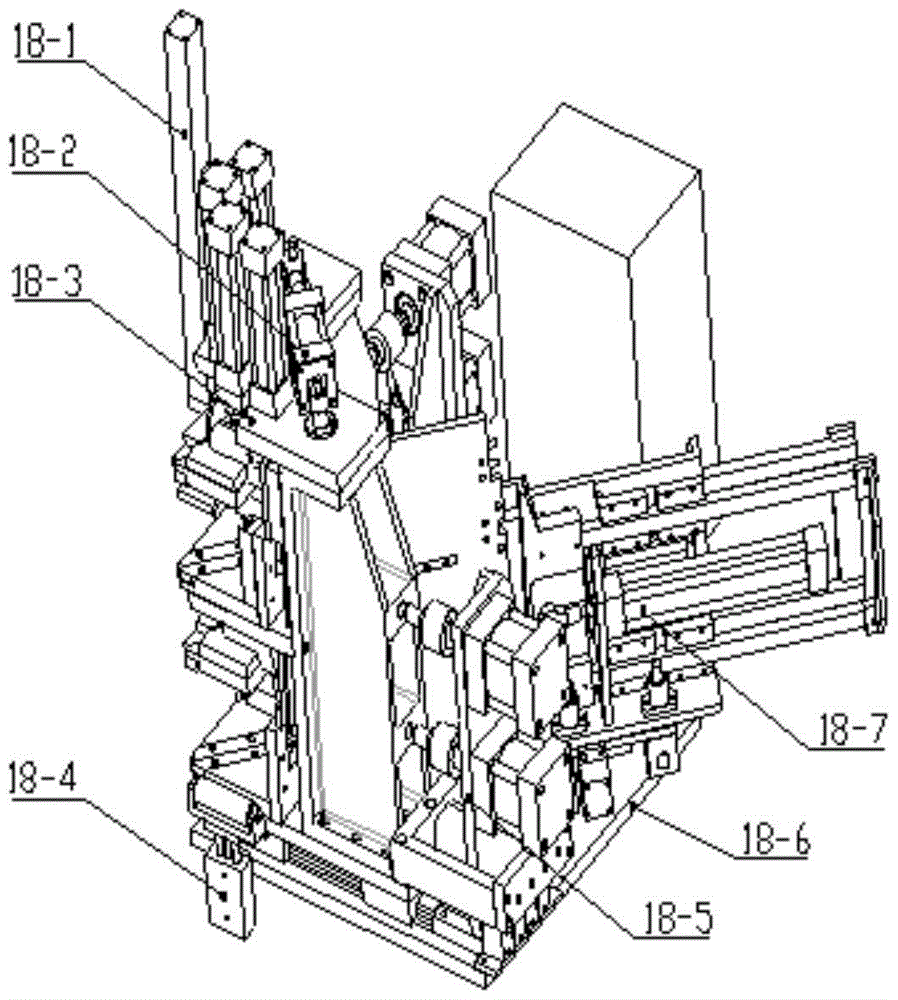

[0046] The double-layer door and window welding machine tool that realizes automatic conversion between seam and seamless welding includes a machine base 6 on which a left frame 2 and a right frame 11 are installed, and the left frame 2 is fixed on The left end of the frame 6, the right frame 11 slides back and forth along the frame 6 left and right under the drive of the right frame moving screw pair 7, one end of the left frame 2 is installed with a left lower head 1, and the other end is installed Left upper head 3, a right lower head 12 is installed at one end of the right frame, and a right upper head 10 is installed at the other end, and described left upper head 3, right upper head 10 move the leading screw pair 4, The upper right machine head moves the lead screw pair 9 and slides back and forth along the direction of the lower left machine head and the lower right mac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com