Synchronous door cam device integrated with car door lock

A technology of synchronous door and integrated car, applied in transportation and packaging, elevators in buildings, etc., can solve the problems of low installation and debugging efficiency, increased failure rate, complex structure, etc., and achieve safe and reliable car door locking and simplified structure , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

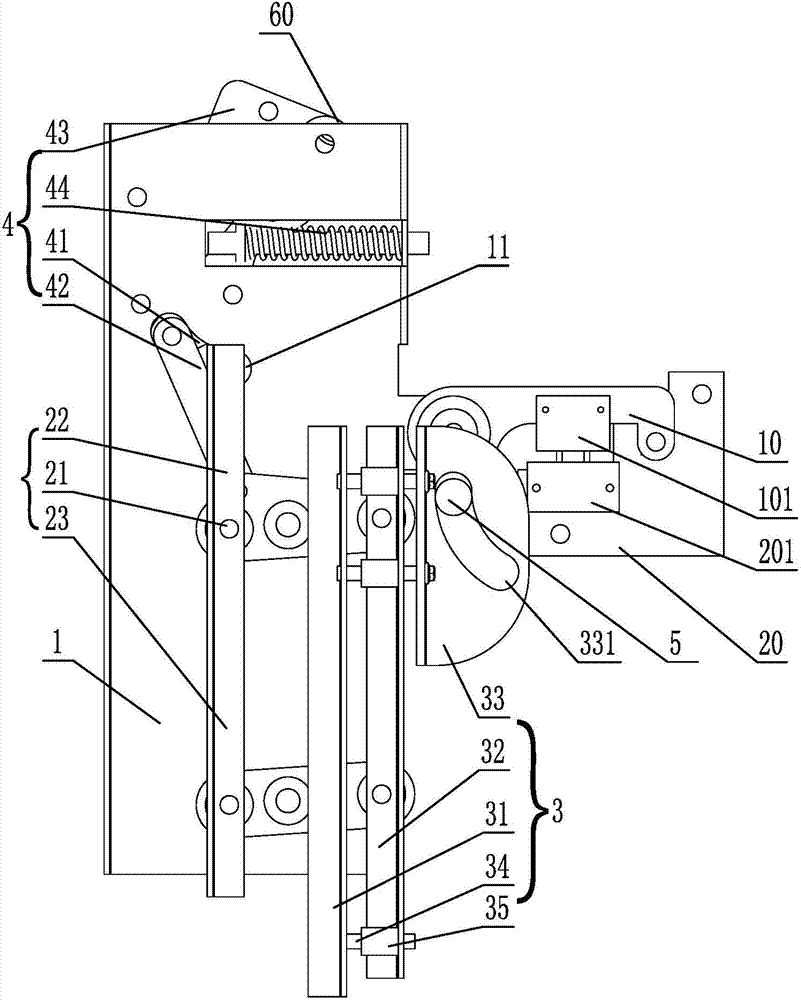

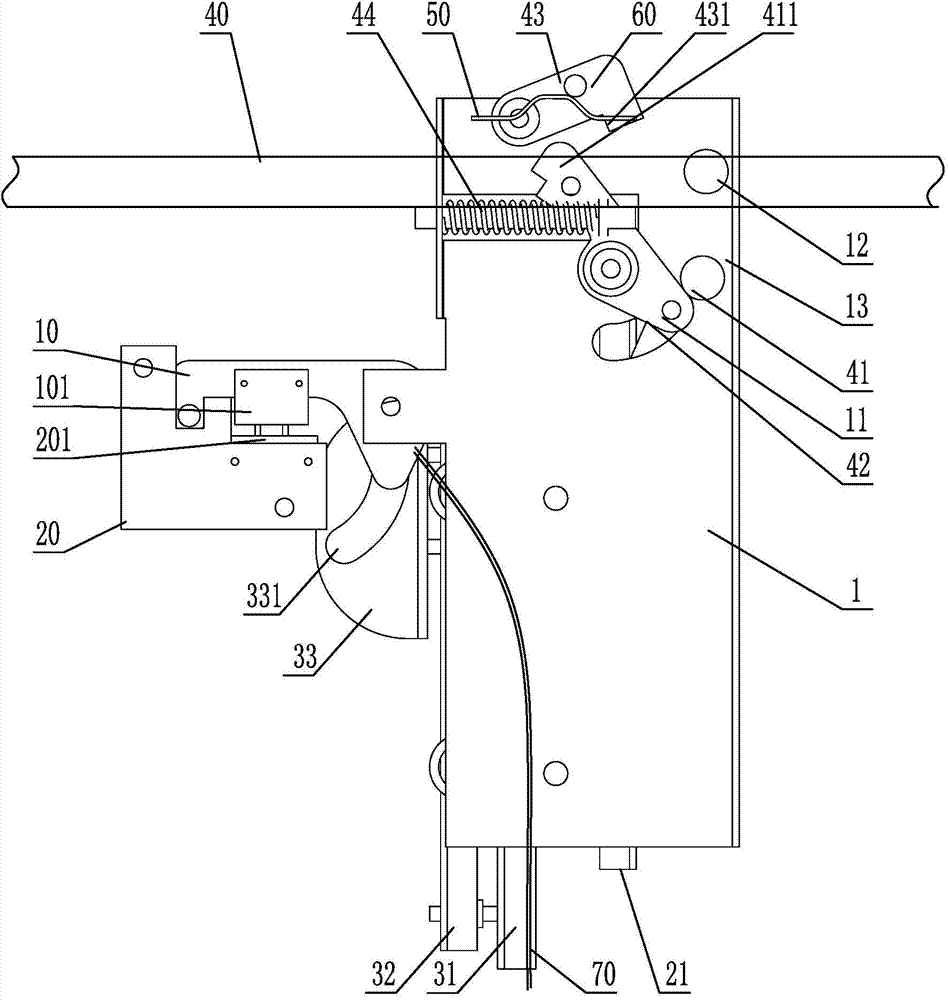

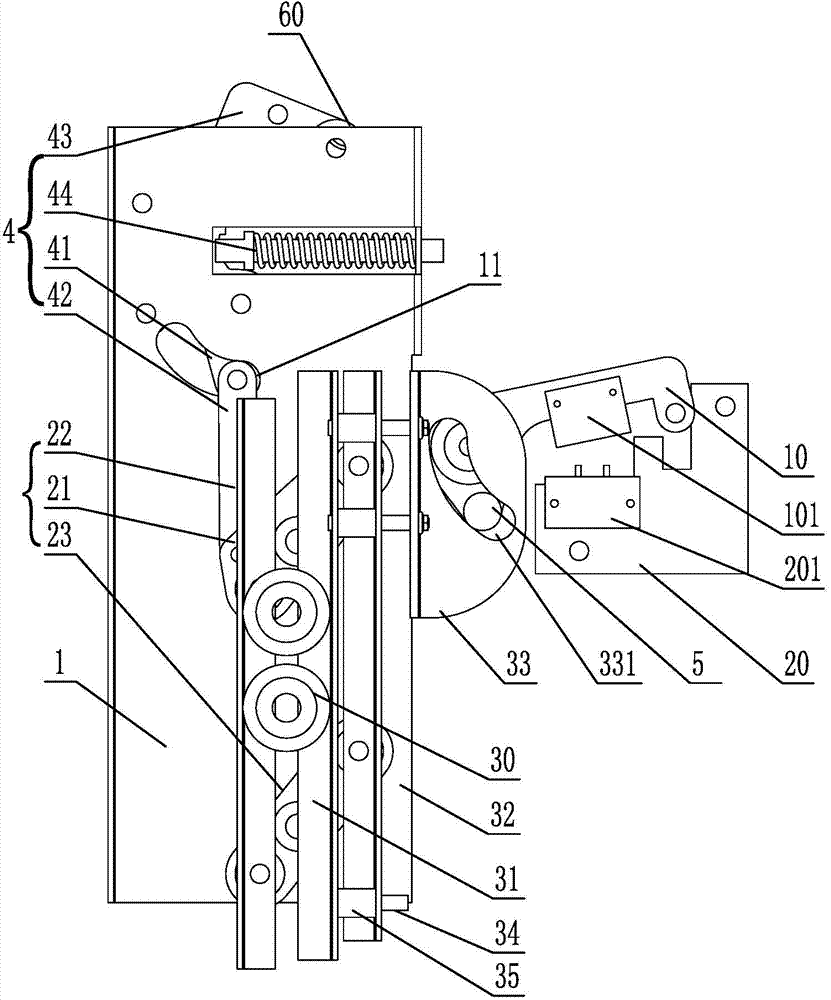

[0039] Such as Figure 1 to Figure 7 As shown, a synchronous door knife device integrating car door locks according to the present invention includes a door machine bottom plate (not shown in the figure), and a door hanging plate for hanging the car door that slides horizontally along the door machine bottom plate. A door knife bottom plate 1 is fixedly installed on the door hanging plate, and a hook seat 20 is fixed on the door machine bottom plate. The left and right inner or outer sides of the door lock roller 30 on the door knife bottom plate 1 are respectively equipped with energy clips. The moving blade swing mechanism 2 and the unlocking blade assembly 3 that hold or interfere with the door lock roller 30, the moving blade swing mechanism 2 is also connected with a transmission assembly 4, and one end of the transmission assembly 4 is hinged on the door that drives the door hanging plate to move. On the door machine transmission belt 40, the other end is hinged with the...

Embodiment 2

[0054] Such as Figure 8 As shown, this embodiment is basically the same as the first embodiment above, the difference is that: the two floor door lock rollers 30 are located on both sides of the moving blade 21 and the unlocking blade 31, and the limit block 32 is located between the moving blade 21 and the unlocking blade 31. Between, its operation principle is the same as that of the above-mentioned embodiment, and will not be repeated here.

Embodiment 3

[0056] Such as Figure 9 As shown, this embodiment is basically the same as Embodiment 1, the difference is that: the bottom plate of the locking hook 10 is provided with an arc-shaped track edge 102, and the unlocking end on the unlocking blade 31 is an unlocking lever 5'. In addition, A conflicting pulley can also be set on the unlocking lever 5' to achieve the purpose of unlocking. The operation principle of this implementation manner is basically the same as that of the above-mentioned embodiment, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com