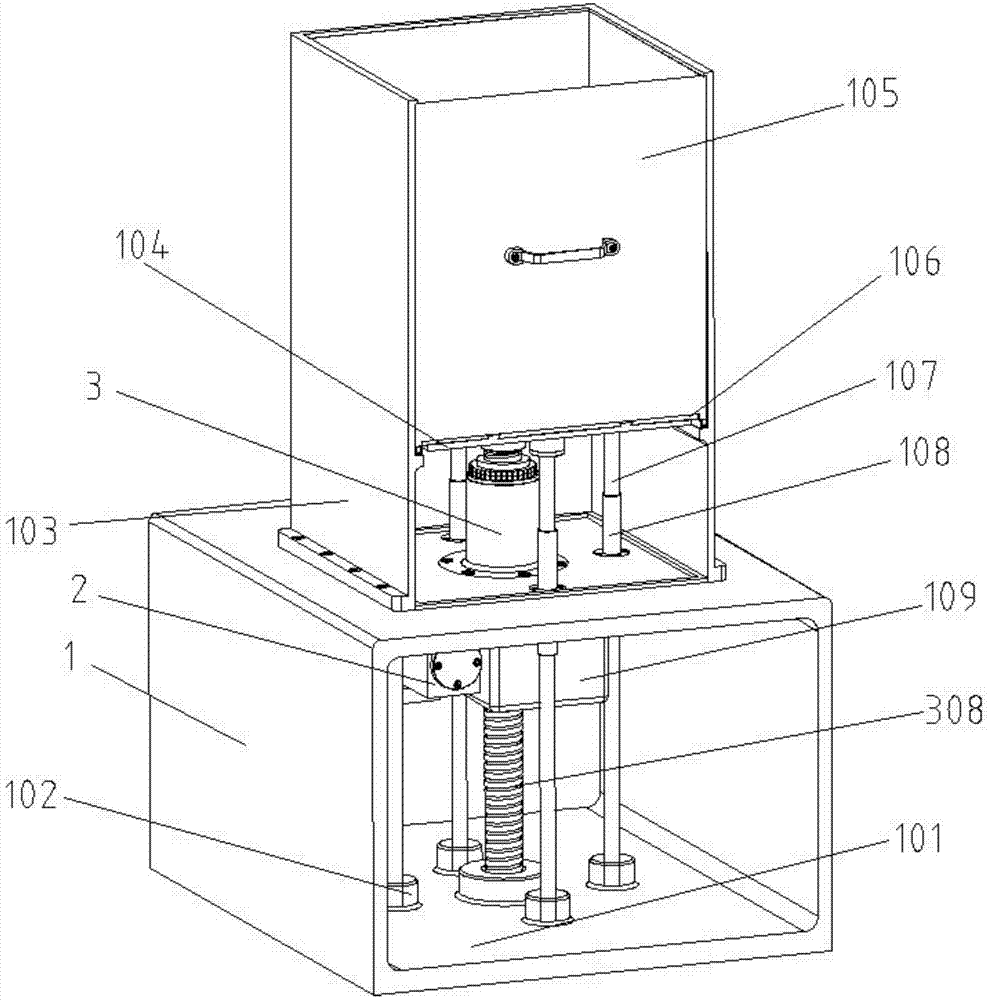

Metal powder electron beam melting lamination layer shaping workbench z-axis movement system

A technology of electron beam melting and layered molding, which is applied in the direction of transmission boxes, transmission components, transmission devices, etc., can solve the problems of low positioning accuracy, slow response, and self-locking, etc., and achieve high positioning accuracy, reduce vibration, and improve reliability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

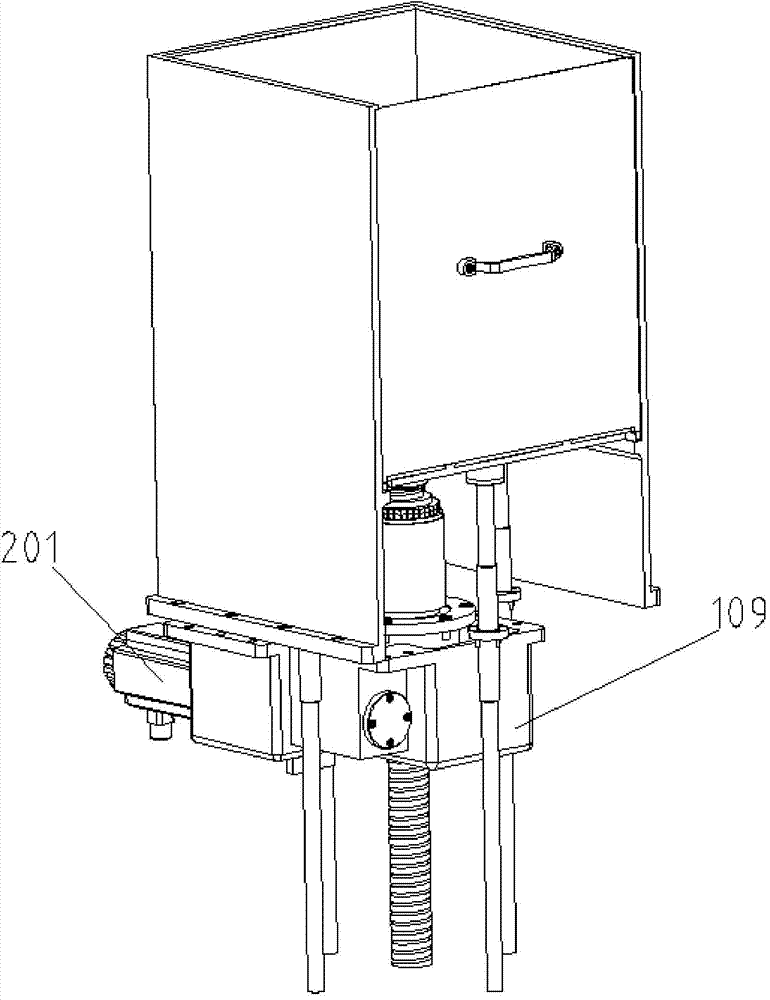

[0031] The top of the second stage speed change mechanism 3 is fixedly connected with the support mechanism 1, the first stage speed change mechanism 2 is fixedly connected with the support mechanism 1, the worm wheel 209 of the first stage speed change mechanism 2 and the lower lead screw nut 303 of the second stage speed change mechanism 3 are used key 315 connection;

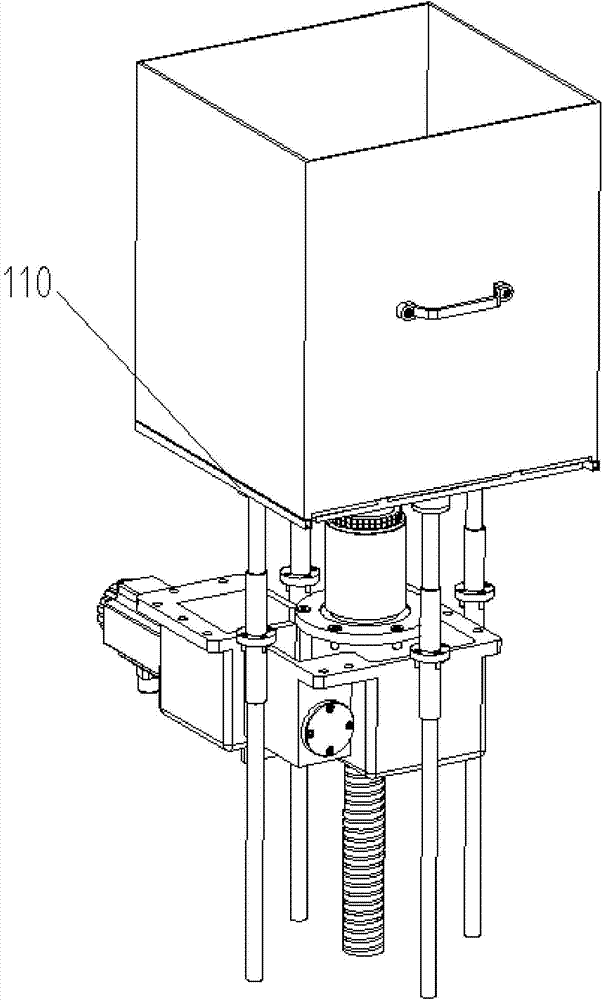

[0032] The structure of the support mechanism 1 is: the worm gear reducer casing 109 is installed on the upper surface inside the bottom box 101, the four guide sleeves 108 are fixedly connected with the top of the bottom box 101, the ring seat 102 is connected with the bottom box 101 inside the bottom The surface is fixedly connected, and is used to accommodate the lower ends of the four guide posts 107 and the lower end of the lead screw 308. The two guide rails 110 are respectively installed inside the outer casing 103 of the construction box, and the telescopic construction box 105 is slidably connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com