Coal-fired boiler combustion control method based on online self-optimization of air excess coefficient

An air excess coefficient, coal-fired boiler technology, applied in the combustion method, combustion control, fuel supply and other directions, can solve the problems of large heat loss of coal-fired boilers, automatic adjustment of the ratio of air to coal, and reduced thermal efficiency of boilers, and achieve savings. Energy, heat loss reduction, emission reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

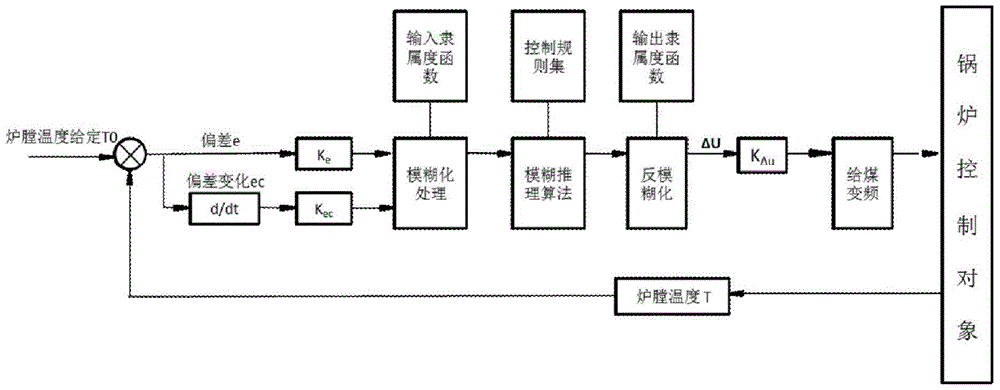

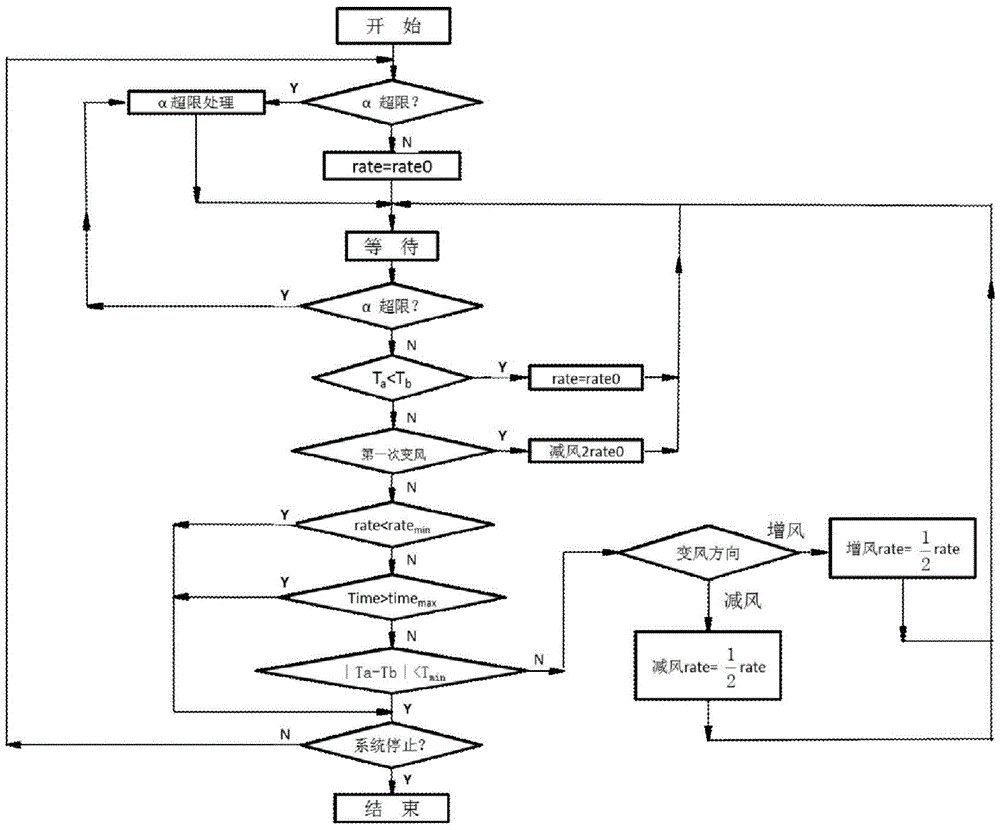

[0036] see figure 1 and figure 2 Shown:

[0037] The coal-fired boiler combustion provided by the present invention is based on the online self-optimization control method of the air excess coefficient, and its specific method is as follows:

[0038] The first step, according to the set value of the furnace temperature, adopts the fuzzy control method to automatically adjust the size of the coal feed, so that the furnace temperature reaches the set range, as follows:

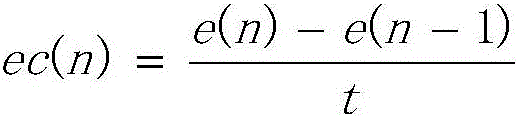

[0039] (1), set the furnace temperature T 0 , using the fuzzy control algorithm, the furnace temperature T at time t detected by the furnace temperature sensor t with a given value T 0 After comparison, the furnace temperature deviation e can be obtained, and the furnace temperature deviation change ec can be obtained through calculation. Δu is the air supply control output increment. The specific formula is as follows:

[0040] e(n)=T t (n)-T 0

[0041] e c ( ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com