Rotary piston heat engine

A heat engine and rotary piston technology, applied to internal combustion piston engines, reciprocating piston engines, engines with rotating cylinders, etc., can solve problems such as low output and unfavorable cylinder rotation, and achieve cost reduction, weight reduction, and size improvement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

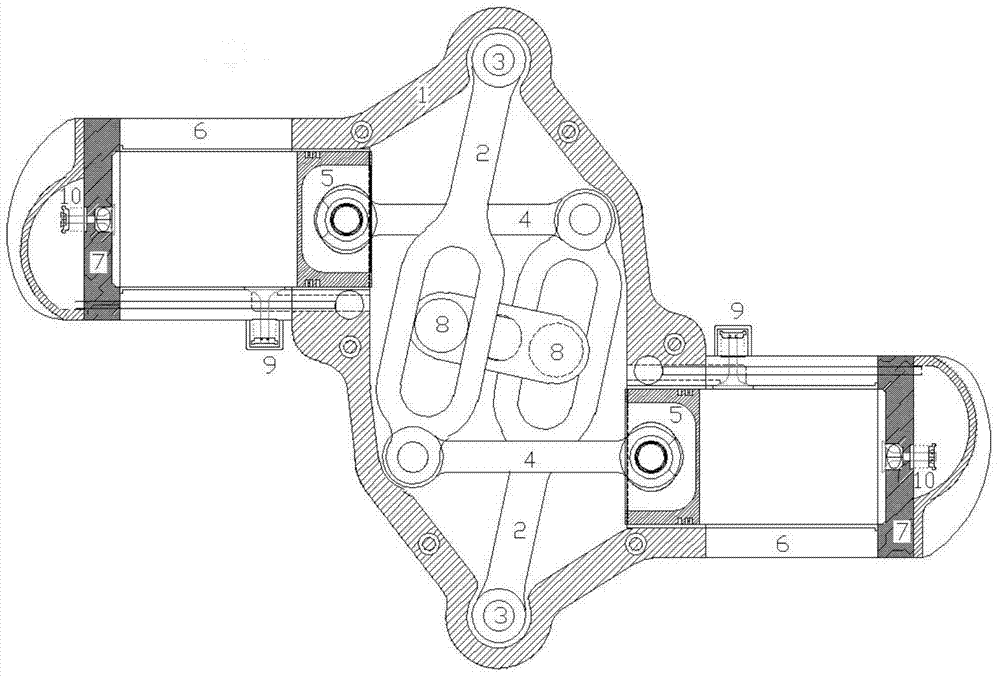

[0019] The rotary piston heat engine of the invention consists of a basic assembly formed by two casings coupled to each other. The housing houses the crankshaft and the levers that drive the pistons, and is coupled to the housing along with the cylinders and other components required for the engine to function properly.

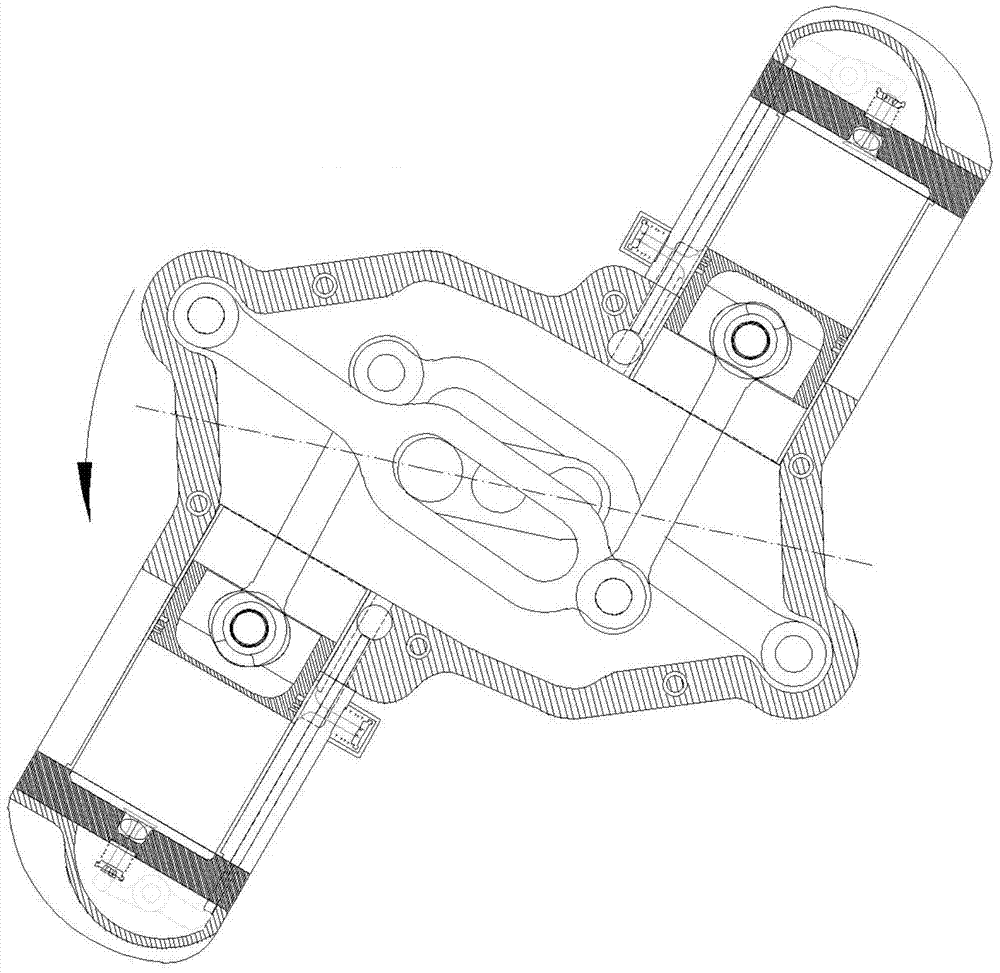

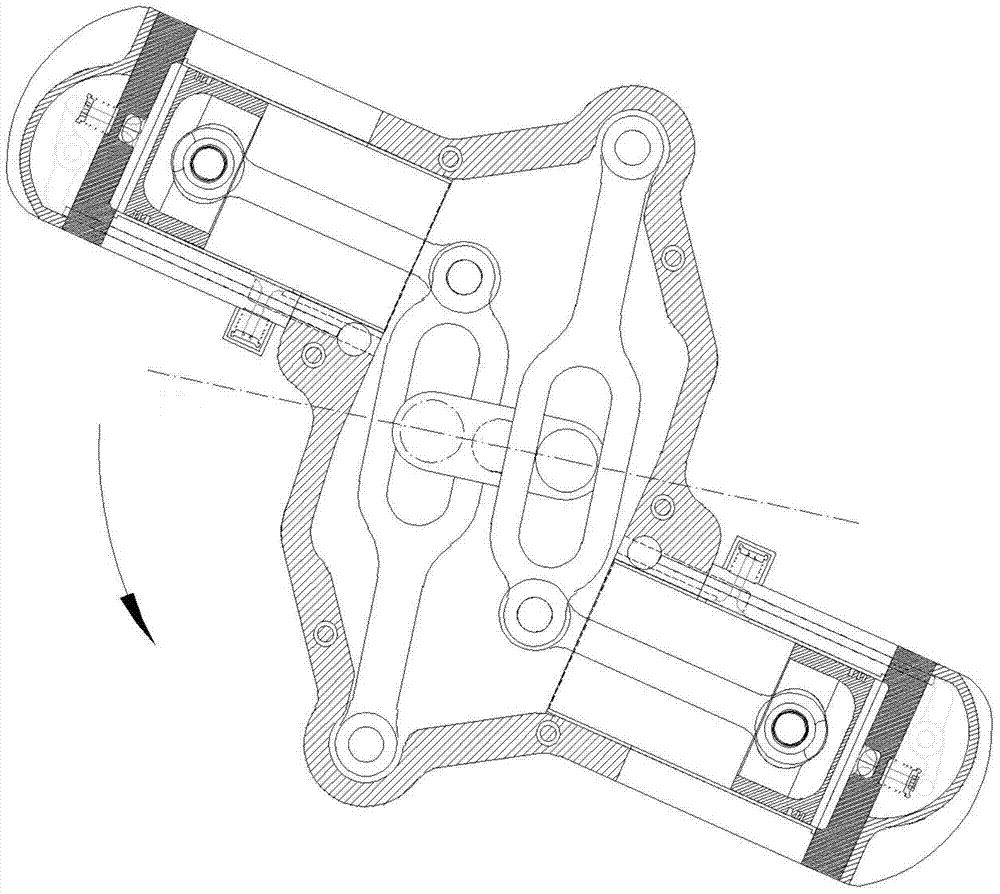

[0020] figure 1 for the floor plan. It can be seen from the figure that the lever (2) is coupled with the housing (1) through the shaft (3), and the connecting rod (4) driving the piston (5) is connected with the other end of the lever. Wherein, the connecting rod moves along the cylinder (6), and the cylinder is coupled with the cylinder head (7). The crankshaft and crank rod (8) are located in the center of the housing. Each crankshaft rod slides along the middle groove of the corresponding lever and drags the piston as the cylinder rotates. figure 2 and image 3 Shows the movement of the piston as the assembly rotates and the crankshaft remains in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com