Five-share plough

A technology of ploughs and ploughs, applied in the field of five-share ploughs, can solve the problems of unbalanced force on the plough frame, reduced ploughing efficiency, damage, etc., so as to avoid the skew of the plough frame, improve the ploughing efficiency, and improve the stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment:

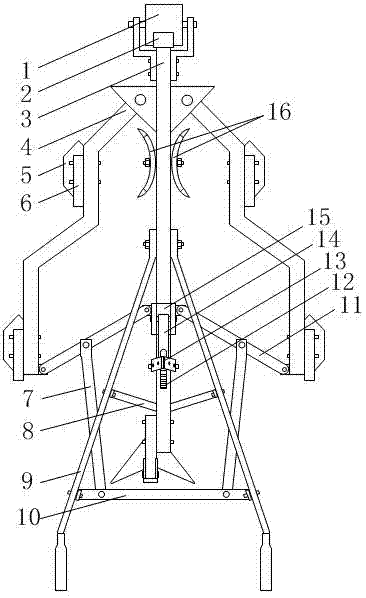

[0017] Such as figure 1 Shown, the five-shared plow of the present invention comprises plow shaft, plowshare 5, connecting rod 11 and handrail.

[0018] The plow shafts include main plow shafts 3 and side plow shafts 4. The side plow shafts are shorter than the main plow shafts, so that the position of the plowshares at the rear of the main plow shaft is relatively behind that of the side plow shafts, avoiding side by side, reducing the resistance of the plow, and improving plowing efficiency. The side plow shafts are arranged symmetrically on both sides of the main plow shaft. The front end of the side plow shaft is connected to the front part of the main plow shaft, and the rear end of the side plow shaft is connected to the rear part of the main plow shaft through a connecting rod. The side shafts include multiple sections, the middle section and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com