Potato harvester

A potato and harvester technology, which is applied to excavator harvesters, harvesters, excavators, etc., can solve the problems of low separation efficiency of potatoes and soil, easy damage of potatoes, inconvenient use, etc. Damage, easy to collect effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

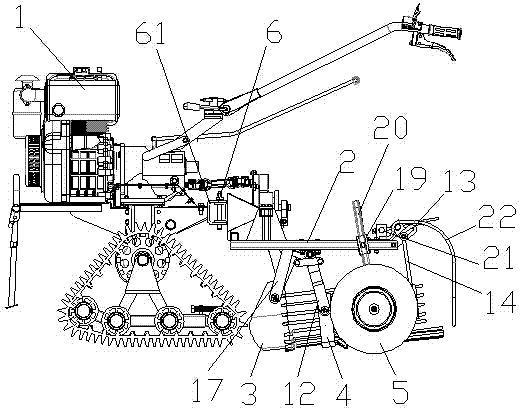

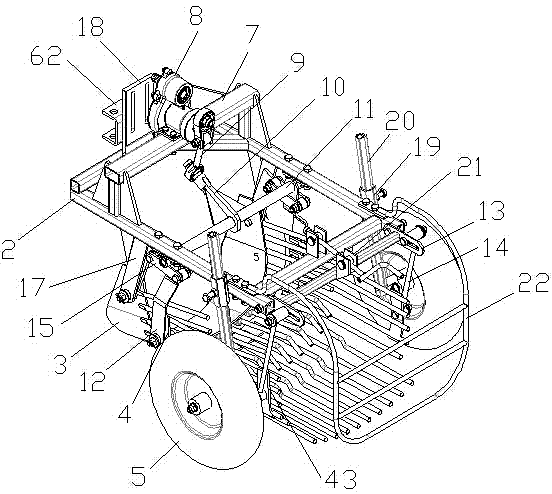

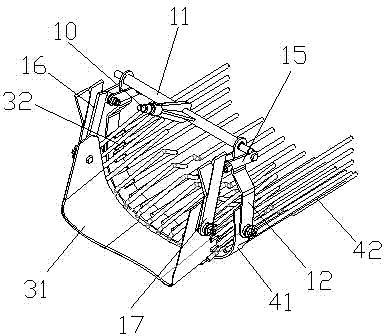

[0028] Example: see figure 1 , a potato harvester, comprising a tiller body 1 and a potato digging mechanism. The tiller body 1 includes a vehicle body, a power drive mechanism, a crawler-type traveling mechanism, a handrail, and a control mechanism. The potato digging mechanism includes a frame 2 , a digging shovel 3 , a screen bucket 4 and two wheels 5 . The output main shaft of the power drive mechanism is used to drive the tiller body 1 to travel, and the output auxiliary shaft is used to drive the potato digging mechanism. The front end of the frame 2 is connected to the rear end of the tiller body 1 through a connector 6 , and the two wheels 5 are located on both sides of the frame 2 . During specific implementation, the connector 6 includes a main connection frame 61 and a secondary connection frame 62, and the main connection frame 61 and the secondary connection frame 62 are fastened and connected by a bolt passing through the main connection frame 61 and the second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com