Clamping device and rotatable driving mechanism with clamping device

A technology for clamping devices and rotating parts, applied in the direction of workpiece clamping devices, clamping devices, positioning devices, etc., can solve problems such as trachea winding, and achieve the effect of avoiding winding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

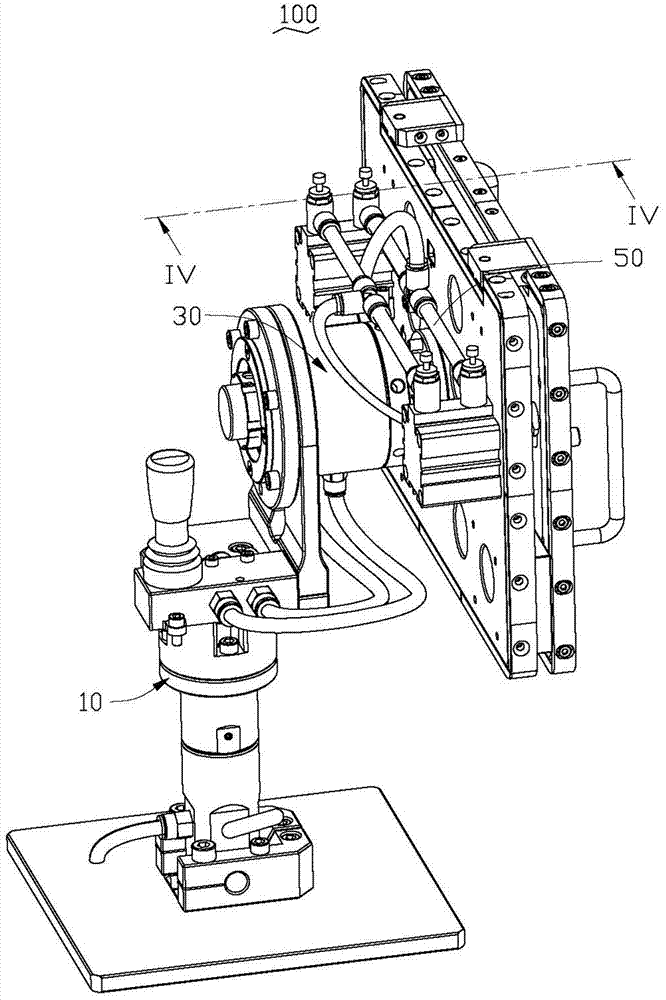

[0016] see figure 1 , the clamping device 100 is used to clamp and rotate the workpiece so that various parts of the workpiece can be processed. The clamping device 100 includes a support frame 10 , an air supply assembly 30 , and a clamping assembly 50 . The air supply assembly 30 is mounted on the support frame 10 , and the clamping assembly 50 is mounted on an end of the air supply assembly 30 away from the support frame 10 . The air delivery assembly 30 is used to deliver air from the support frame 10 to the clamping assembly 50 for the clamping assembly 50 to clamp the workpiece.

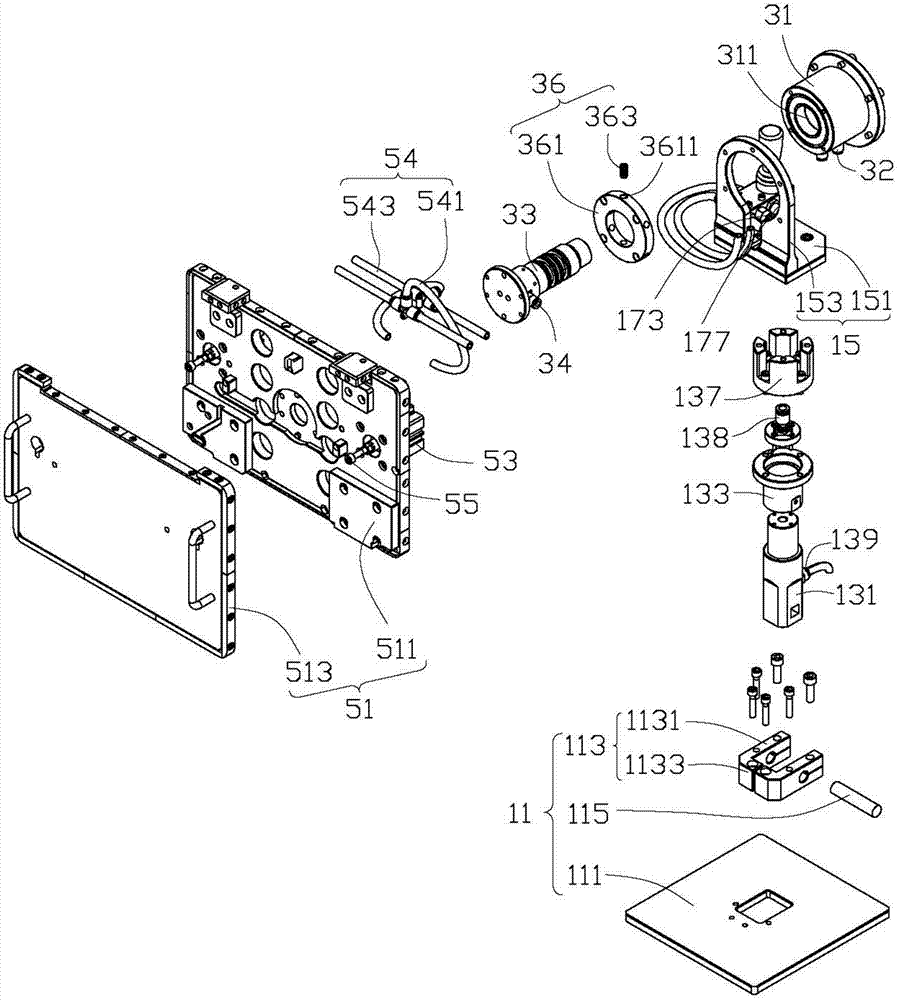

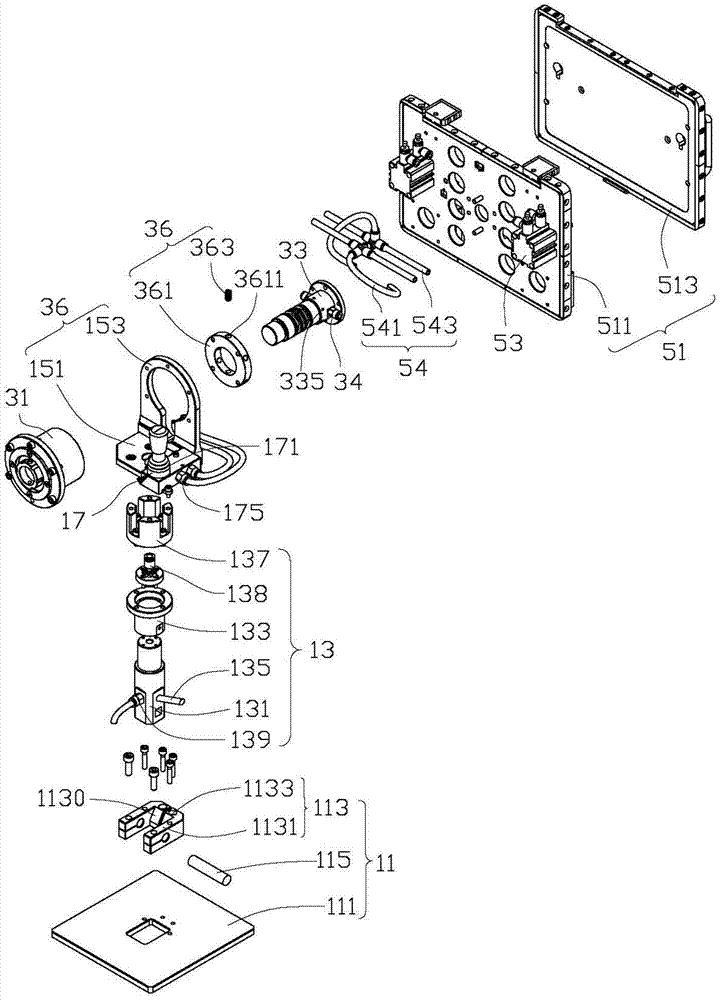

[0017] Please also refer to figure 2 and image 3 , the support frame 10 includes a fixed component 11 , a rotating component 13 , a mounting part 15 and a reversing component 17 . The fixing assembly 11 includes a base plate 111 , two opposite fixing pieces 113 and a connecting rod 115 . The two fixing parts 113 are relatively fixed on the base plate 111 . Each fixing member 113 include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com