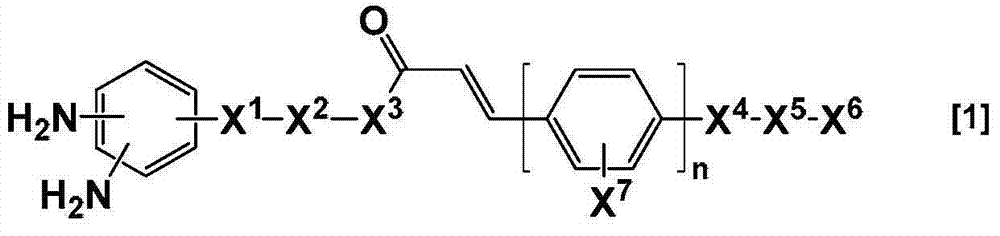

Liquid crystal aligning agent, liquid crystal alignment film, and liquid crystal display element using same

An amine compound and single bond technology, which is applied in the field of liquid crystal alignment treatment agent, liquid crystal alignment film and liquid crystal display elements using it, can solve problems such as circuit damage, dust generation, liquid crystal alignment film defects, etc., and achieve stable pretilt angle, reliable sex high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

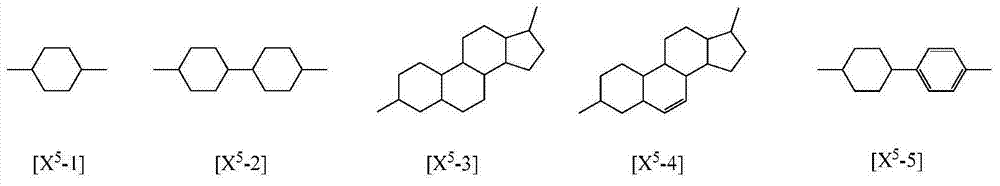

Method used

Image

Examples

Embodiment 1

[0463] Add 4-iodophenol 1 (22.0g, 0.100mol), potassium carbonate (20.7g, 0.150mol) and 130ml (mmol) of dimethylformamide in a four-necked flask, stir under nitrogen atmosphere, then heat up to 80 ℃. After reaching 80° C., 1-bromodecane (17.9 g, 0.0809 mol) was added dropwise over 30 minutes, and stirred for 1 hour after the dropwise addition was completed. After confirming the disappearance of 1-bromodecane by GC (gas chromatography), the solvent was distilled off, 120 ml of toluene and 150 g of pure water were added for extraction, and the aqueous layer was removed. Then, 100 ml of 1N NaOH was added to the organic layer for extraction, and the aqueous layer was removed. The obtained organic layer was dried with anhydrous magnesium sulfate, and then magnesium sulfate was filtered off, and the obtained organic layer was evaporated to remove the solvent under reduced pressure to obtain compound 2 (yield 26.9 g, 0.0747 mol, yield 92.3%). The structure of compound 2 is obtained ...

Embodiment 2

[0468]A solution obtained by mixing 3,5-dinitrobenzyl alcohol 3 (39.6g, 0.200mol), triethylamine (26.3g, 0.260mol) and 200ml of tetrahydrofuran was stirred at 0°C under a nitrogen atmosphere, and a 30-minute A solution obtained by mixing acryloyl chloride (21.7 g, 0.240 mol) and 40 ml of tetrahydrofuran was added dropwise to this solution. After the dropwise addition, the mixture was stirred for another 4 hours. After the reaction was completed, the solvent was distilled off, and 300 g of water was added to the obtained crude product, followed by stirring at 25° C. for 30 minutes in a slurry state. Then, the reaction solution was filtered, and the solid content was dried at 70° C. under reduced pressure for 3 hours to obtain compound 4 (yield 48.7 g, 0.193 mol, yield 96.5%). The structure of compound 4 is obtained by 1 H-NMR analysis to confirm.

[0469] 1 H-NMR (CDCl 3 ): δ9.02(t, 1H, J=2.4Hz, Ar-H), 8.58(m, 2H, Ar-H), 6.54(dd, 1H, J=17.6, 1.2Hz, -CH=CH 2 ),6.27-6.20(m,1...

Embodiment 3

[0473] Compound 2 (25.3g, 0.0702mol), compound 4 (21.1g, 0.0837mol), palladium chloride-acetonitrile complex (0.572g, 2.21mmol), tri(o-tolyl)phosphine (1.28g, 4.21mmol ), tripotassium phosphate (22.7g, 0.107mol), the suspension of dimethylacetamide 170g was decompressed to 50Torr with a diaphragm pump at room temperature, and the pressure was restored with nitrogen, and the above action was repeated 10 times, and the reactor was removed. and the oxygen contained in dimethylacetamide. Then, the temperature was raised, and the mixture was stirred at 110° C. for 3 hours under a nitrogen atmosphere. After the reaction, the solvent was distilled off, followed by extraction with 200 g of water and 250 g of chloroform. The separated aqueous layer was extracted twice with 250 g of chloroform, and the obtained organic layer was dried over anhydrous magnesium sulfate. Magnesium sulfate was filtered off, the obtained organic layer was evaporated to remove the solvent under reduced pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com