A pipeline connection structure

A connection structure and pipe body connection technology, applied in mechanical equipment, couplings and other directions, can solve the problems of difficult alignment of the pipe parts, unstable connection of the buckle parts, and inconvenient operation of the buckle, so as to achieve simple structure manufacturing, Easy assembly and good airtightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

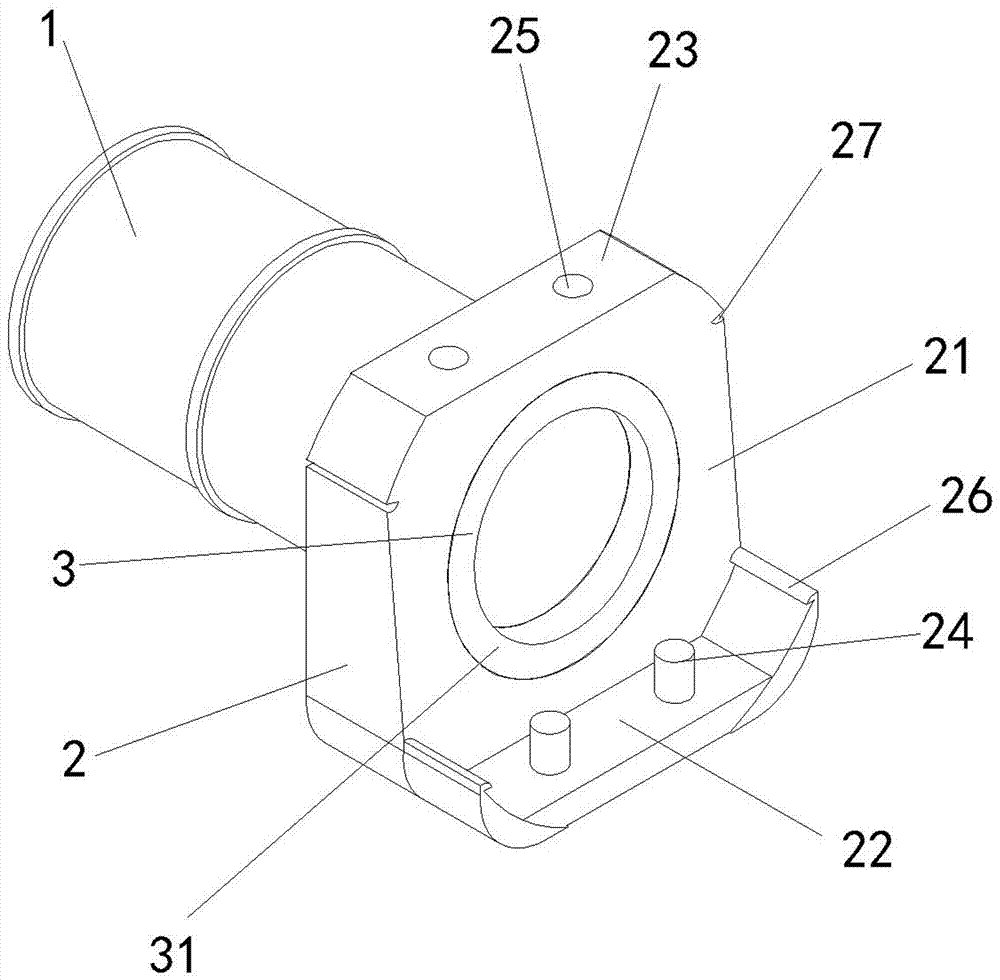

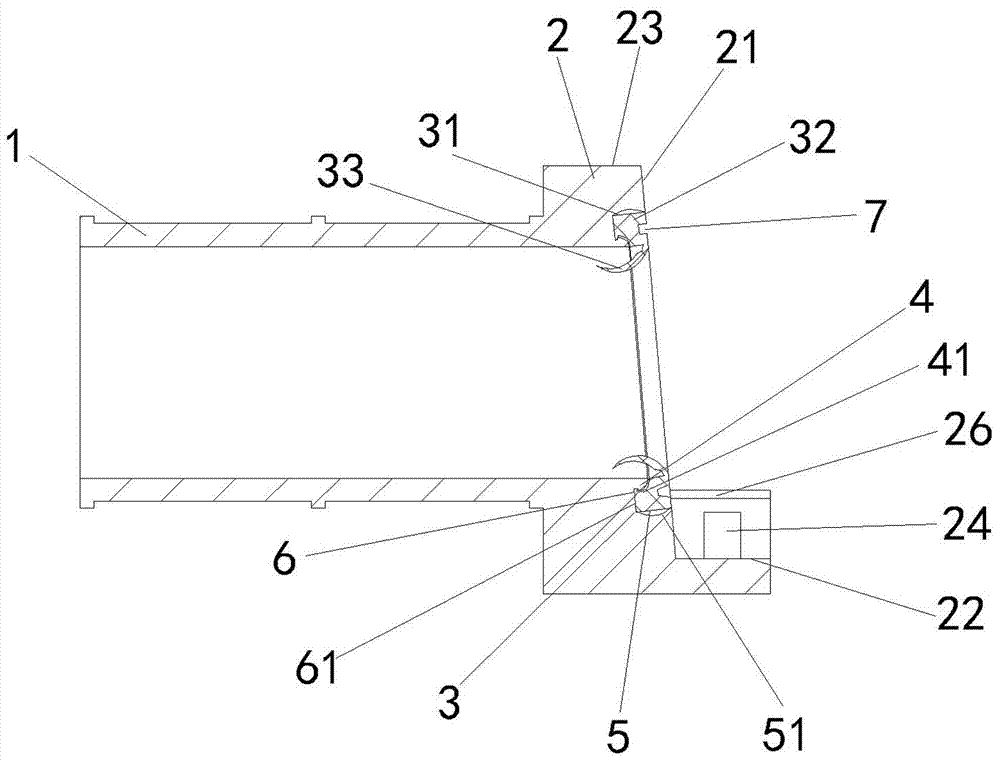

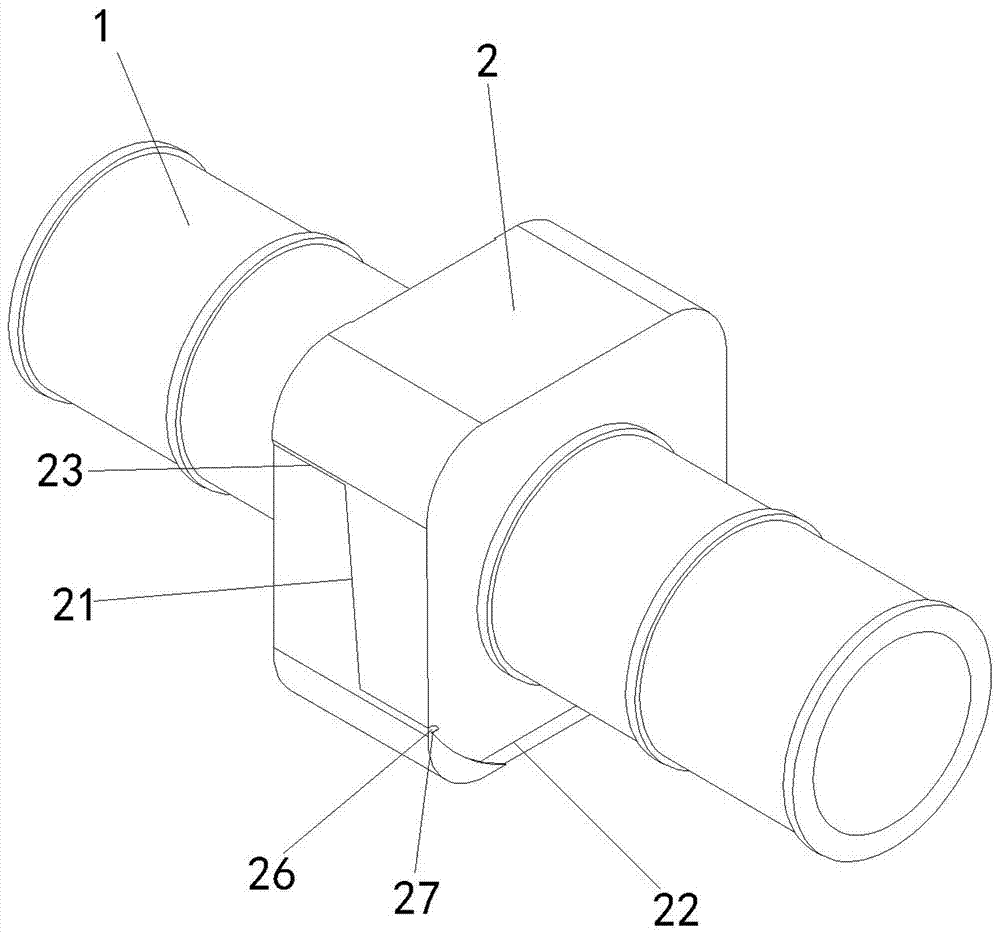

[0020] Embodiment one, such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 A pipe connection structure shown includes a pipe body connection part 1 and a pipe body fastening part 2, the pipe body connection part 1 is used to connect rigid or flexible pipes, and the pipe body fastening part 2 is used to connect the other pipe Joint, the pipe body buckle part 2 is radially larger than the pipe body connection part 1, the pipe body buckle part 2 includes an inclined pipe end joint surface 21, and the edge of the pipe end joint surface 21 is bent and connected to the pipe body buckle part 2 Moreover, the first limiting surface 22 and the second limiting surface 23 parallel to the axis of the tube body connecting portion 1 are fixedly connected to the tube body connecting portion 1 and the tube body fastening portion 2 as a whole. The cross-section of the buckle part 2 of the pipe body is trapezoidal, and a second limiting surface 23 is connected to the upper base...

Embodiment 2

[0025] In the second embodiment, a sealing part 3 is provided in the fastening part 2 of the pipe body, and the sealing part 3 includes an annular depression 31 and a sealing member cooperating with the depression 31. The sealing member includes a sealing body 32 arranged in the depression 31 and a flexible The reversible tubular sealing auxiliary body 33 connected to the sealing body 32 , the free end of the sealing auxiliary body 33 can be turned over between the first limiting surface 22 side and the second limiting surface 23 side of the pipe end joint surface 21 . A sealing part 3 is provided in the pipe body fastening part 2, and the sealing part 3 includes an annular depression 31 and a sealing member cooperating with the recess 31. The sealing member includes a sealing member body 32 arranged in the recess 31 and one end flexibly connected to the sealing member The reversible tubular sealing auxiliary body 33 of the body 32 , the free end of the sealing auxiliary body 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com