a pipe joint

A technology of pipe joints and pipe heads, applied in the direction of pipes/pipe joints/pipes, hose connection devices, flange connections, etc., can solve the problem of unstable connection of the buckle part, difficult alignment of the pipe part, and inconvenient buckle operation. and other problems, to achieve the effect of simple structure manufacturing, good airtightness and convenient assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

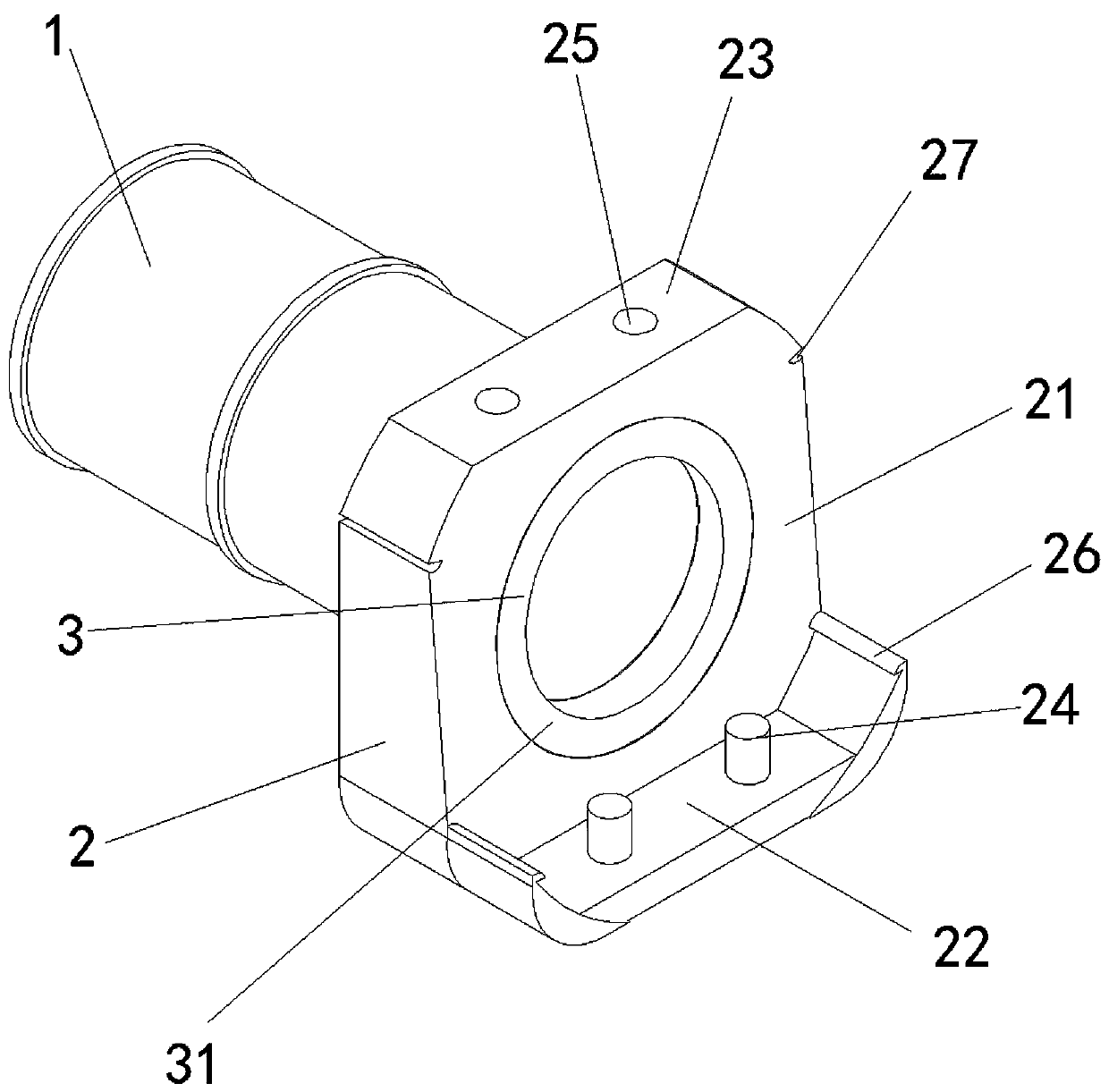

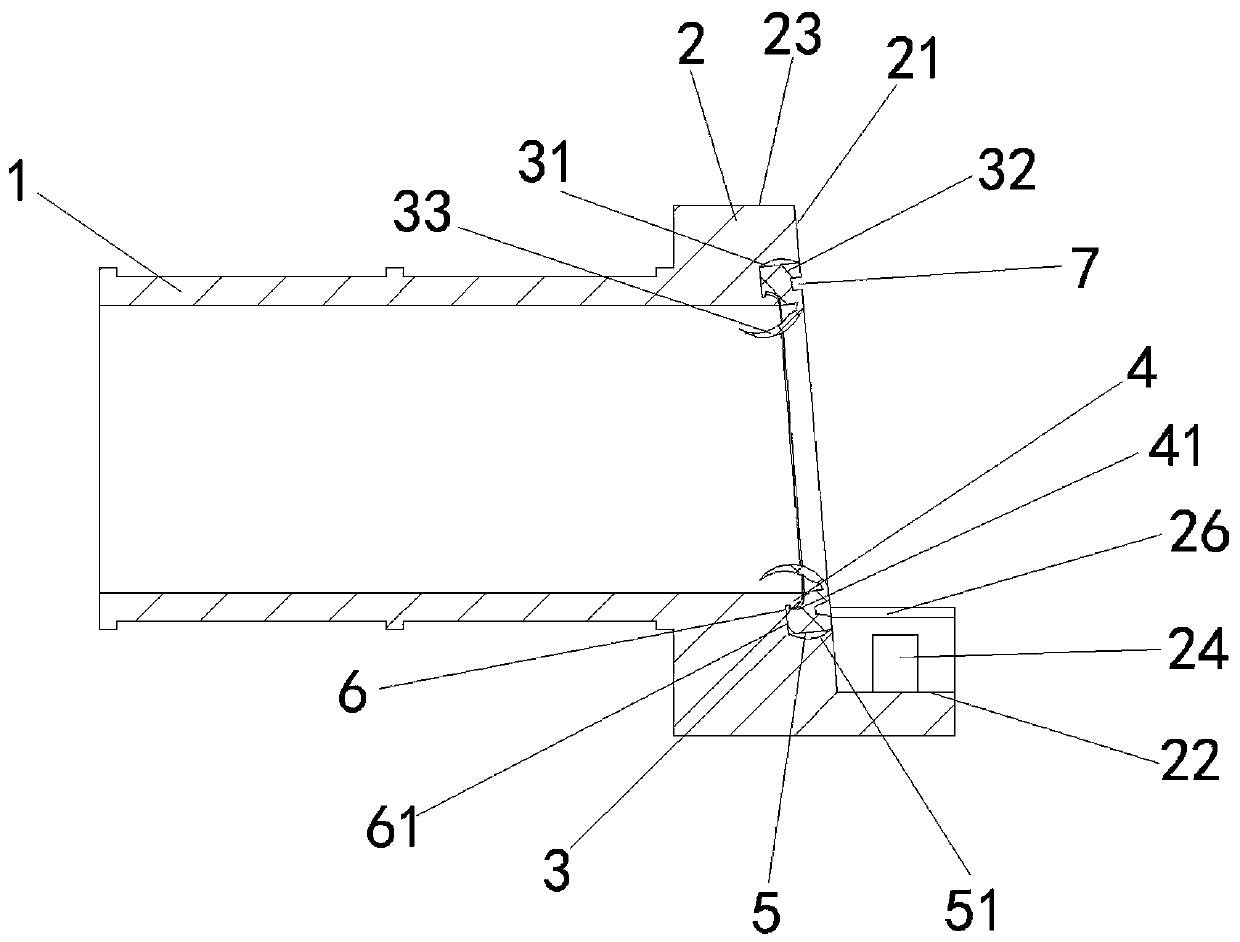

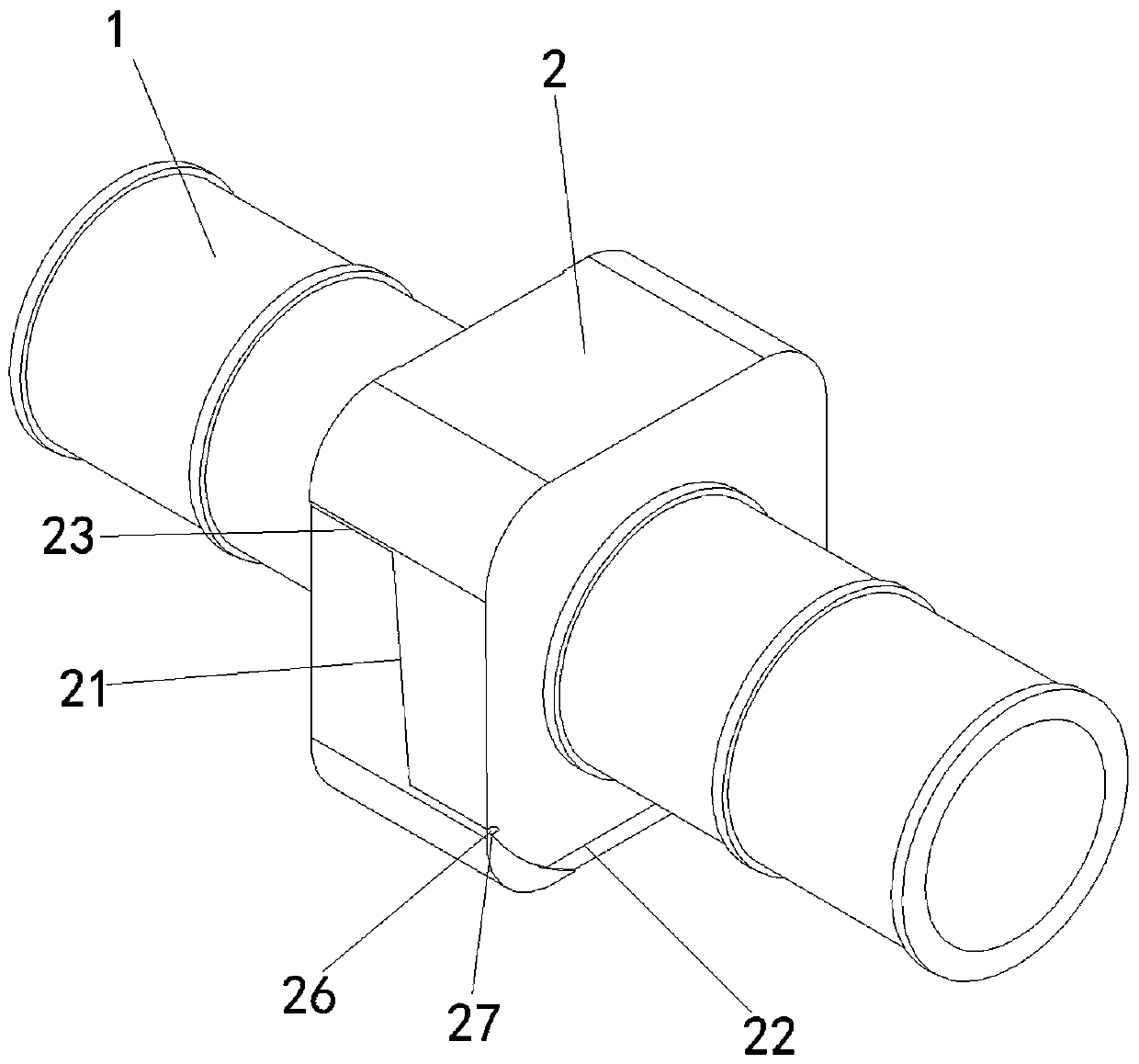

[0023] Embodiment one, such as figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 A pipe joint is shown, which is used to connect rigid or flexible pipes in one direction, and connects the same another pipe joint in the other direction, including a pipe body connecting part 1 and a pipe head fastening part 2, the pipe body The connecting part 1 is used to connect rigid or flexible pipes, the pipe head fastening part 2 is used to connect the other pipe joint, the pipe head fastening part 2 is radially larger than the pipe body connecting part 1, and the pipe head fastening part 2 includes an inclined The pipe end joint surface 21, the edge of the pipe end joint surface 21 is turned and connected with the first limit surface 22 and the second limit surface 23 included in the pipe head fastening part 2 and parallel to the axis of the pipe body connection part 1, and the pipe body The connecting part 1 and the buckling part 2 of the pipe head are fixedly connected as a...

Embodiment 2

[0028] Embodiment 2, a sealing part 3 is provided in the fastening part 2 of the pipe head, and the sealing part 3 includes an annular depression 31 and a seal that is installed in cooperation with the annular depression 31. The seal includes a seal body 32 disposed in the annular depression 31 and One end is flexibly connected to the reversible tubular sealing auxiliary body 33 of the seal body 32, and the free end of the sealing auxiliary body 33 can be turned over between the first limiting surface 22 side and the second limiting surface 23 side of the pipe end joint surface 21 . A sealing part 3 is provided in the buckle part 2 of the pipe head, and the sealing part 3 includes an annular depression 31 and a sealing member fitted with the annular depression 31. The sealing member includes a sealing member body 32 arranged in the annular depression 31 and one end flexibly connected to The reversible tubular sealing auxiliary body 33 of the seal body 32 , the free end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com