Improved variable frequency air conditioner

An inverter air conditioner, an improved technology, applied in the direction of mechanical equipment, fluid circulation arrangements, refrigeration components, etc., can solve the problems of small flow changes, unsatisfactory energy efficiency ratio, and unsatisfactory heating energy efficiency ratio. Thermal energy efficiency ratio, the effect of improving energy efficiency ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

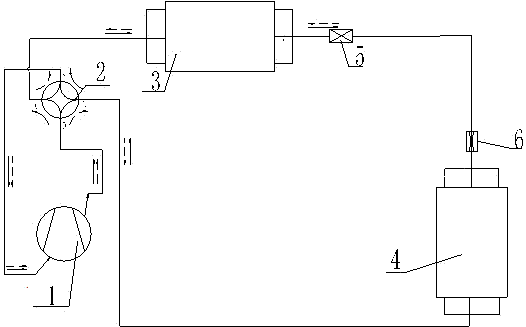

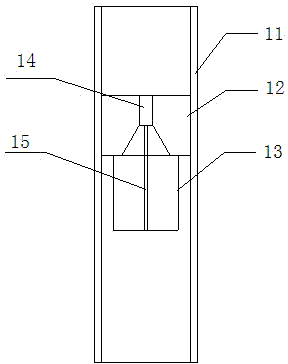

[0037] Such as figure 1 As shown in , 2, an improved inverter air conditioner includes a compressor 1, a four-way valve 2, a condenser 3 and an evaporator 4, and the delivery pipeline connecting the condenser 3 and the evaporator 4 is arranged according to the cooling flow direction. A variable flow throttling device and a refrigeration check valve device, the conduction direction of the refrigeration check valve device points to the condenser 3, the refrigeration check valve device is close to the evaporator 4, and the refrigeration check valve is installed at a distance from the inlet of the evaporator in the cooling direction End 80cm, the cooling check valve device adopts the nozzle check valve 6, the variable flow throttling device adopts the electronic expansion valve 5, and the heating throttling is realized by adjusting the opening of the electronic expansion valve 5, the nozzle check valve 6 includes the valve body 11. The movable spool 13 and the fixed valve seat 12,...

Embodiment 2

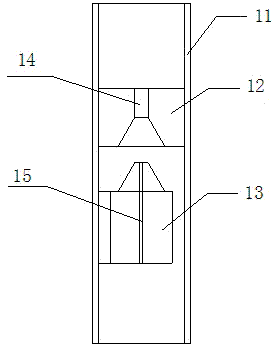

[0043] Such as image 3 As shown, the rest is the same as that of Embodiment 1, except that three nozzle check valves 6 arranged in parallel are used as the three-way refrigeration check valve device and the electronic expansion valve 5 is used as the variable flow throttling device. Realize unexpected significant increase in APF value.

[0044] The following is a year-to-year year-to-year experiment on the energy efficiency ratio of an inverter air conditioner using three nozzle check valves 6 as a three-way refrigeration check valve device and one electronic expansion valve 5 as a variable flow throttling device according to national standards. The experimental data is tabulated as follows:

[0045]

[0046] It can be seen from the above experimental data that the APF value of the inverter air conditioner using the prior art is 4.797, while the APF values obtained by using the technical solution of the present invention are 5.841, which is significantly improved.

Embodiment 3

[0048] Such as Figure 4 As shown, the rest is the same as that of Embodiment 1, except that the one-way valve 8 and the capillary tube 9 arranged in parallel are used as a one-way refrigeration check valve device and the electronic expansion valve 5 is used as a variable flow throttling device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com