Antifreezing-agent multi-path large-temperature-rise heat-extracting air-exhausting vapor-source cascading heat pump

A multi-process, antifreeze technology, applied in the direction of fluid circulation arrangement, damage protection, lighting and heating equipment, etc., can solve the problem of difficult to realize the defrosting of the reheating coil in winter, increase the power consumption of circulating water pump and antifreeze pump, common Single-stage heat pump cycle does not consider other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

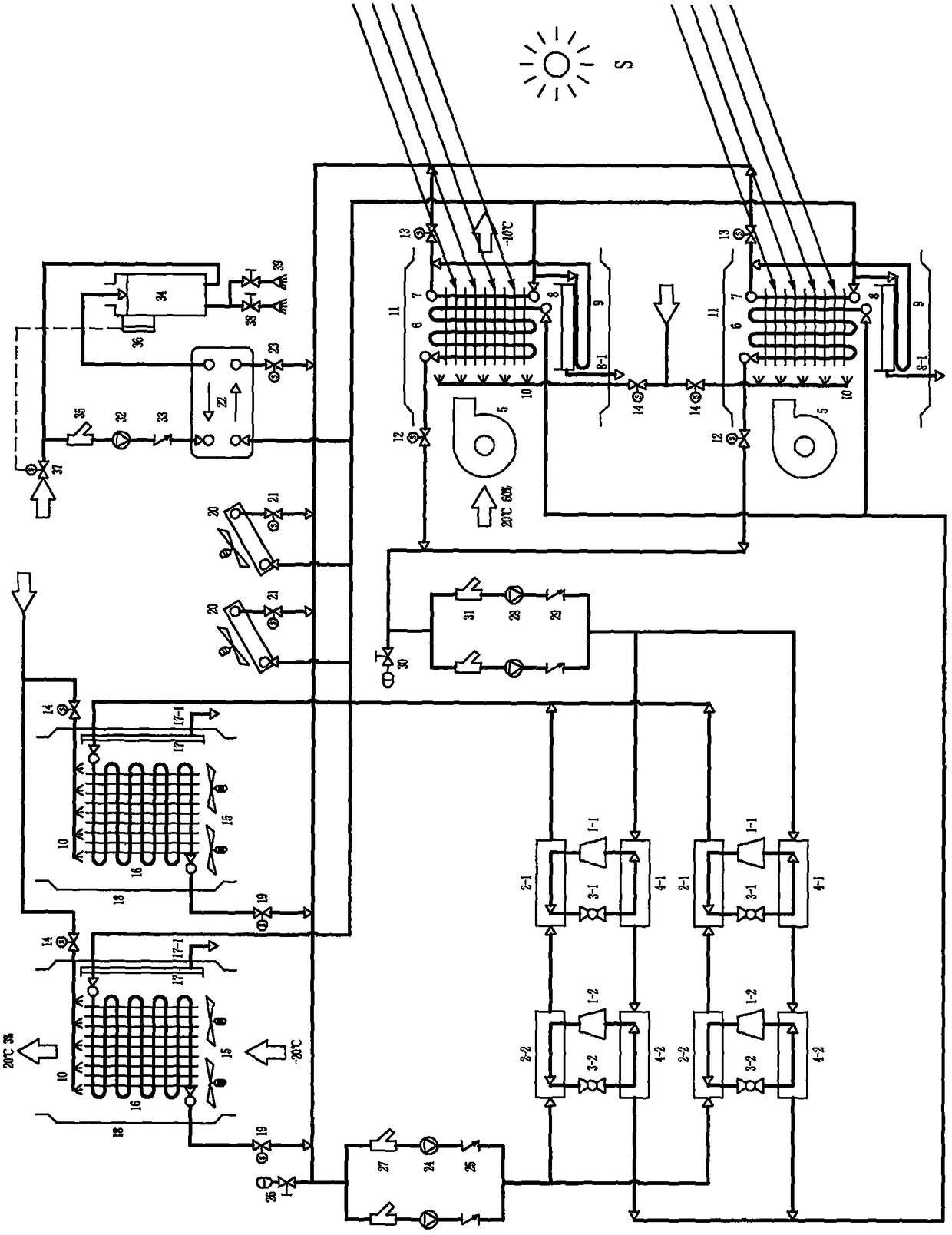

[0075] The antifreeze proposed by the present invention has multiple processes and large temperature rise to obtain heat and exhaust air and water vapor source cascade heat pump. figure 1 As shown, the specific description is as follows: 4 sets of cascade heat pumps operate in parallel, and the antifreeze side of the high-temperature heat source side heat exchanger 4-1 of each set of cascade heat pumps and the antifreeze side of the low-temperature heat source side heat exchanger 4-2 are connected in series. The circulating water sides of the low-temperature use-side heat exchanger 2-2 and the high-temperature use-side heat exchanger 2-1 of the cascade heat pump are connected in series, and the heat of the circulating water side drives the reverse 3-flow fresh air coil 16 of 8 fresh air units 18 connected in parallel , 200 fan coils 20, 1 hot water heater 22, 10 defrosting coils 7 and ice melting coils 9 of the exhaust air regenerator 11, and the antifreeze side cooling capacit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com