Automatic fish killing machine

An automatic and organic technology, applied in fish processing, fish cleaning/descaling, slaughtering, etc., can solve the problem of low efficiency of manual fish killing, and achieve the effect of simple and efficient design, improved production efficiency, and simple manufacturing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with accompanying drawing and embodiment.

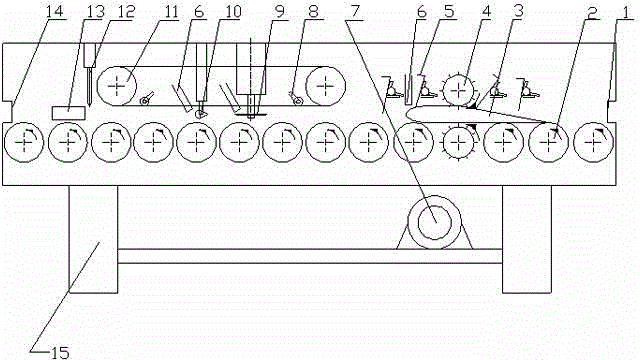

[0013] An automatic fish killing machine, which consists of a feed port 1, a conveying stick 2, a fish body 3, a descaling stick 4, a pressing plate 5, a water spray device 6, a motor 7, a distance adjusting device 8, a disc knife for cutting fish belly 9, Visceral removal device 10, pinch belt 11, fish head removal device 12, push plate 13, discharge port 14 and body 15, discharge port 14 is installed on the left side of the body 15, and feed port 1 is installed on the right side, A row of conveying sticks 2 is installed below the feeding port 1, and fish bodies 3 are placed on the carrying rods 2 to realize the transportation of the fish bodies. On the left side of the feeding port 1, a descaling stick 4, a pressing plate 5, and a water spray device 6 are sequentially installed to realize Scale scraping and cleaning are integrated, the left side of the wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com