a filter device

A filter device and filter element technology, which is applied in the direction of solid separation, separating solids from solids with airflow, chemical instruments and methods, etc., can solve problems such as technical limitations and inability to discharge, and achieve good filtering effect, easy maintenance, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in combination with specific embodiments and accompanying drawings.

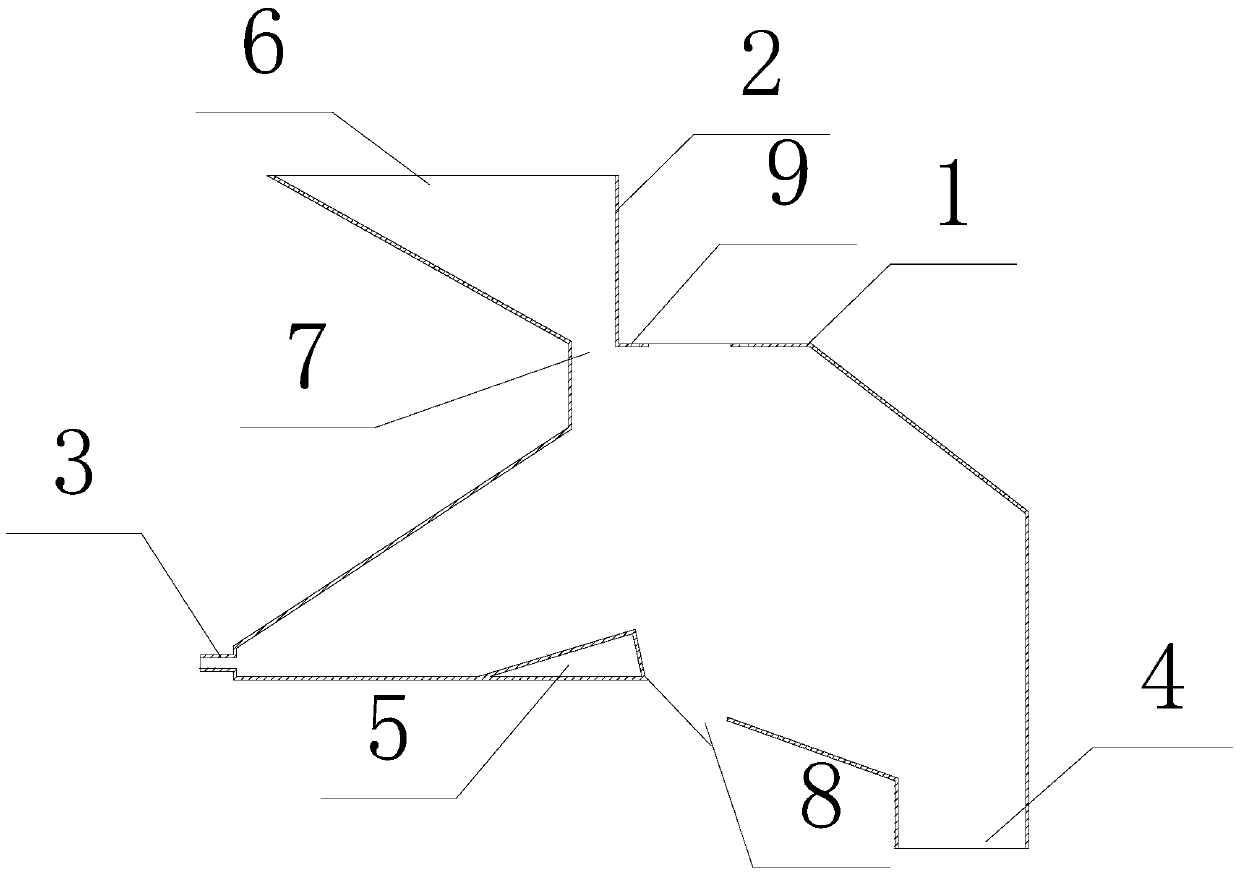

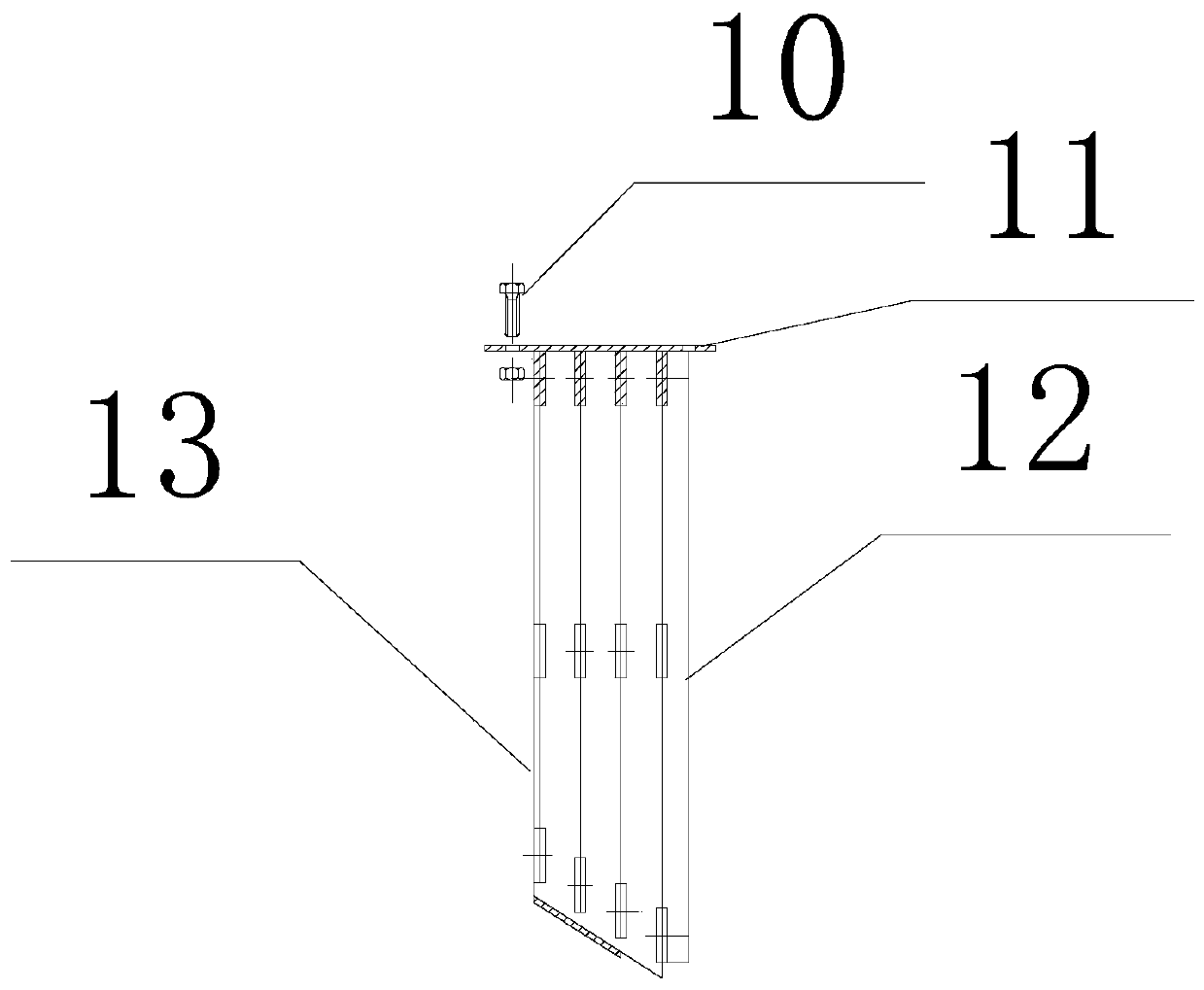

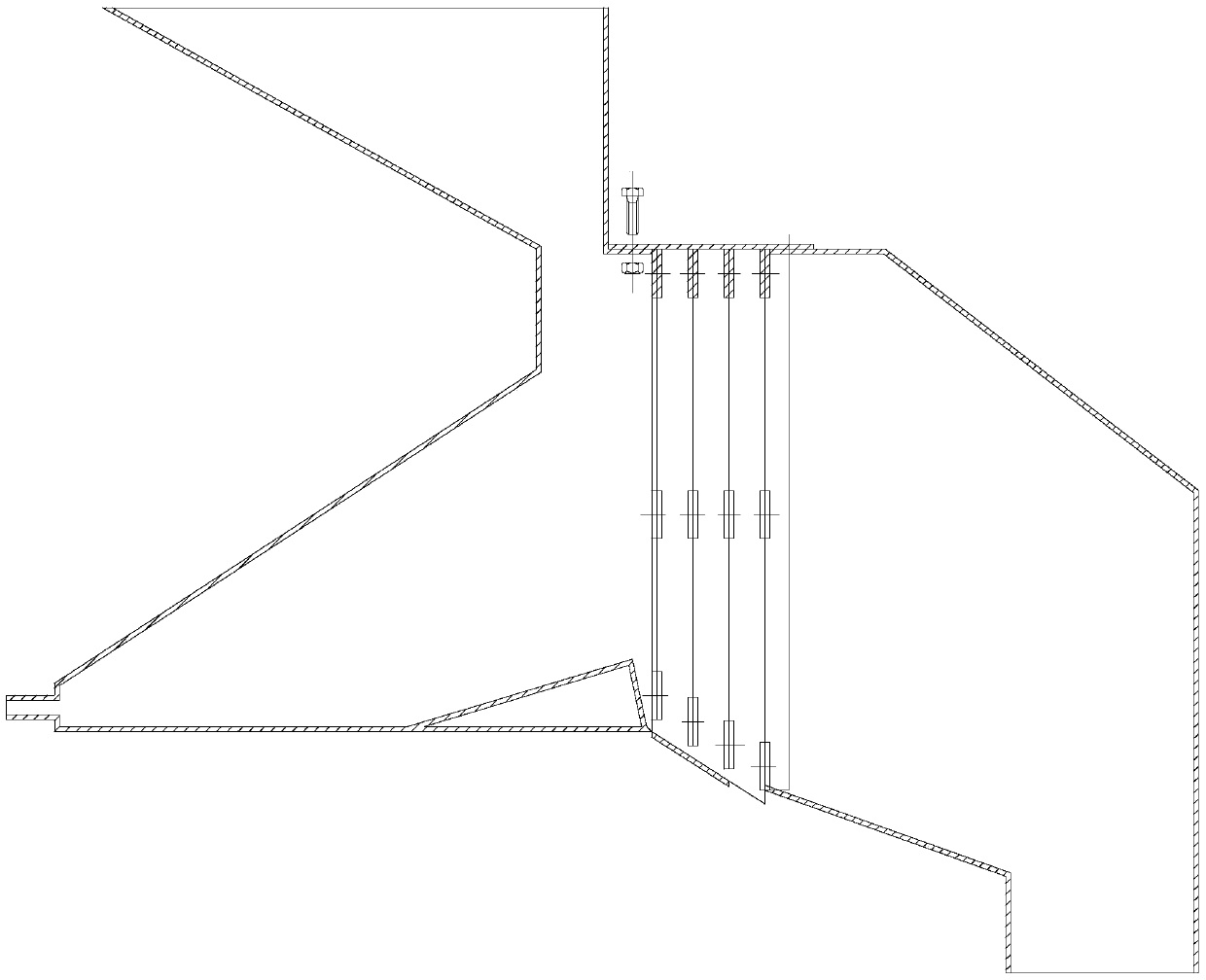

[0019] refer to figure 1 and figure 2 As shown, the housing 1 of the filtering device is provided with a hopper 2, and the hopper 2 is a bucket-shaped structure in which the outlet 7 is smaller than the inlet 6. The housing 1 is also provided with a compressed air inlet 3 and a particle outlet 4. The bottom of the housing 1 is also provided with a deflector 5, the relative angle between the deflector 5 and the bottom of the housing is 15 degrees, and the filter element 13 is a 4-layer filter core plate 12, according to the degree of filtration according to 30 mesh, 70 mesh, 100 mesh, The 140 meshes are arranged from coarse to fine and are connected by a connecting plate 11 . The connecting plate 11 is also provided with connecting bolts 10 matching the assembly holes 9 on the upper part of the housing 1 .

[0020] Before filtering, the filter el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com