Patents

Literature

31results about How to "Increase molecular density" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

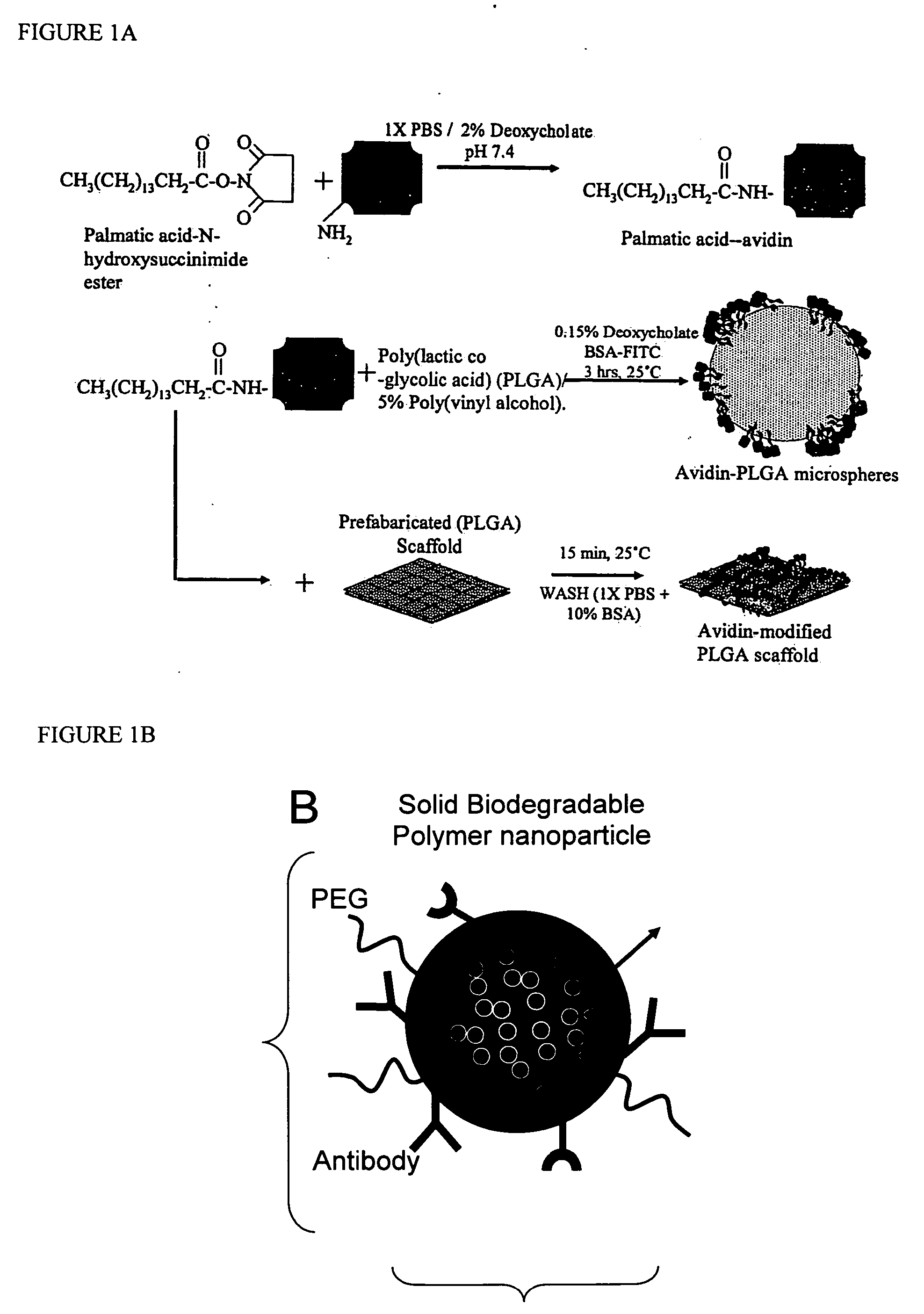

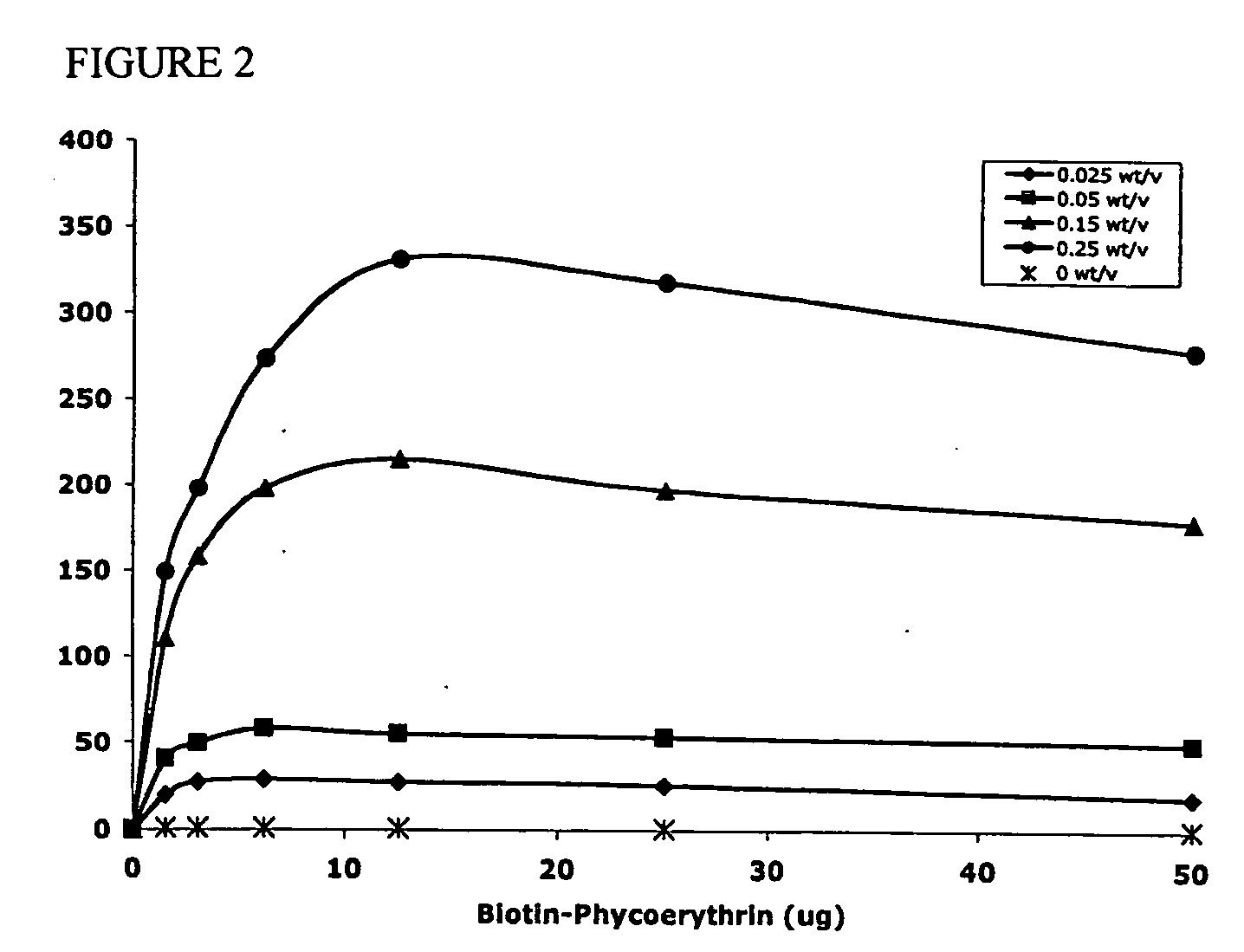

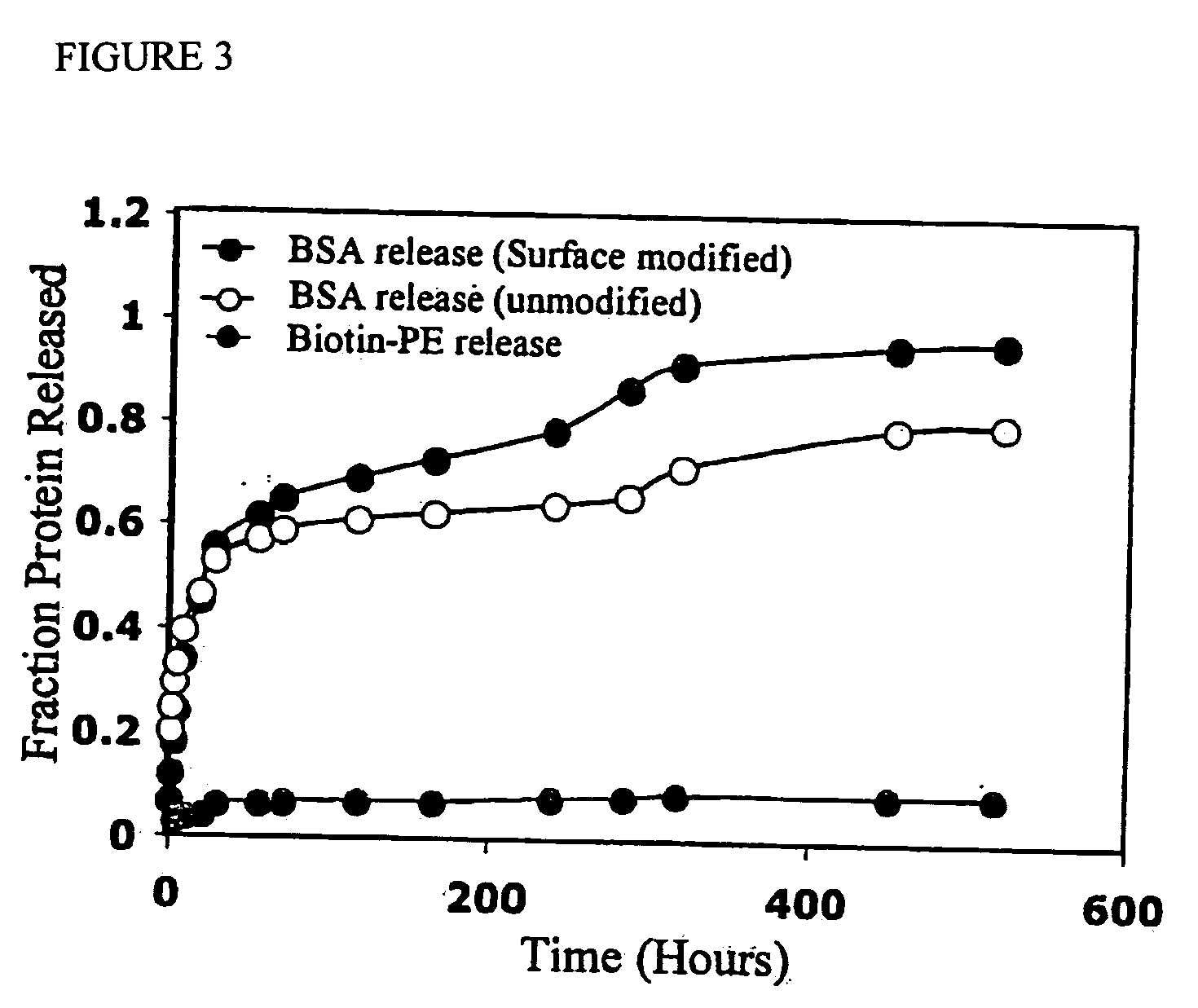

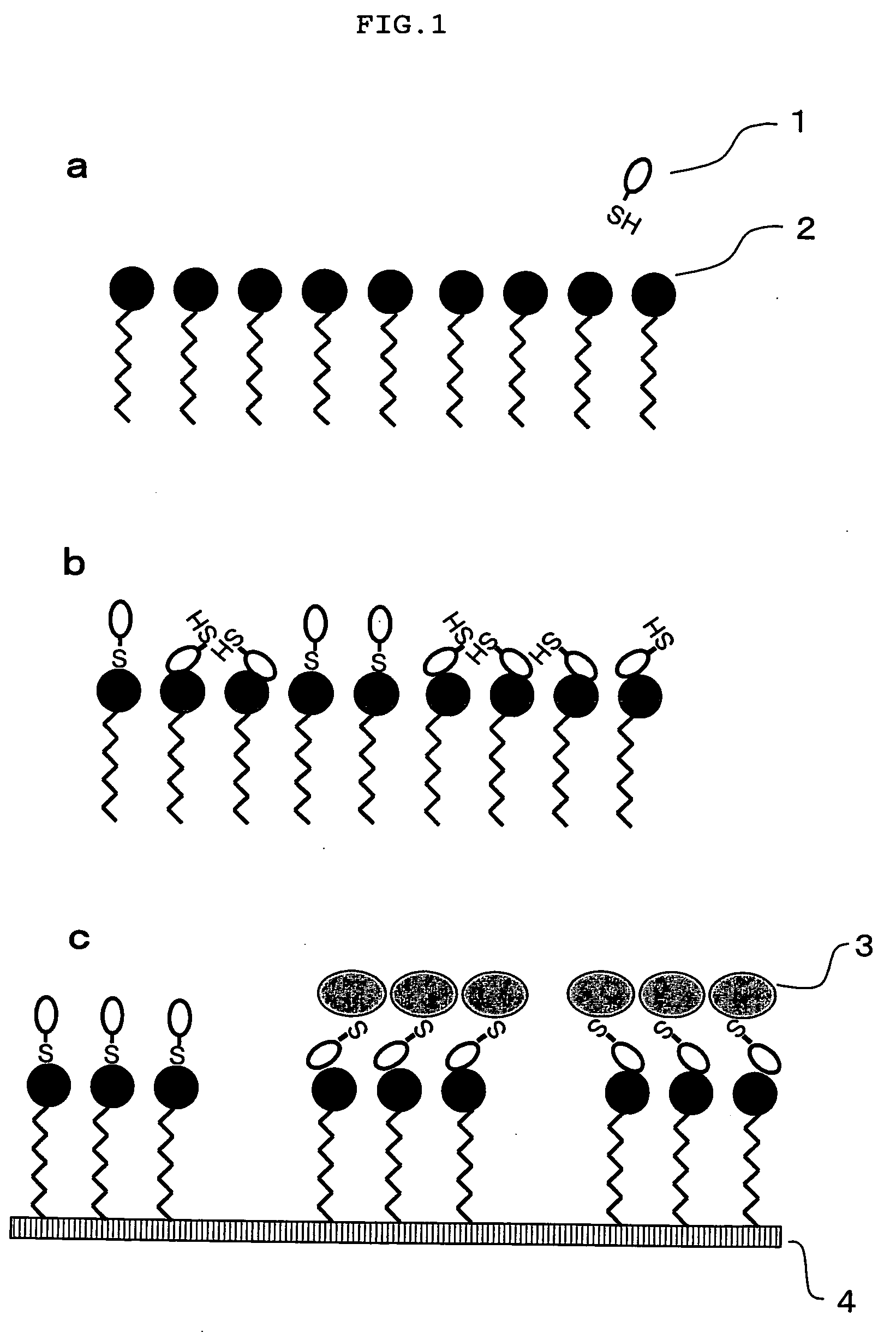

Targeted and high density drug loaded polymeric materials

ActiveUS20060002852A1Increase molecular densityHigh densityPowder deliveryBiocideAntigenWound dressing

Polymeric delivery devices have been developed which combine high loading / high density of molecules to be delivered with the option of targeting. As used herein, “high density” refers to microparticles having a high density of ligands or coupling agents, which is in the range of 1000-10,000,000, more preferably between 10,000 and 1,000,000 ligands per square micron of microparticle surface area. A general method for incorporating molecules into the surface of biocompatible polymers using materials with an HLB of less than 10, more preferably less than 5, such as fatty acids, has been developed. Because of its ease, generality and flexibility, this method has widespread utility in modifying the surface of polymeric materials for applications in drug delivery and tissue engineering, as well other other fields. Targeted polymeric microparticles have also been developed which encapsulate therapeutic compounds such as drugs, cellular materials or components, and antigens, and have targeting ligands directly bound to the microparticle surface. Preferred applications include use in tissue engineering matrices, wound dressings, bone repair or regeneration materials, and other applications where the microparticles are retained at the site of application or implantation. Another preferred application is in the use of microparticles to deliver anti-proliferative agents to the lining of blood vessels following angioplasty, transplantation or bypass surgery to prevent or decrease restenosis, and in cancer therapy. In still another application, the microparticles are used to treat or prevent macular degeneration when administered to the eye, where agents such as complement inhibitors are administered.

Owner:YALE UNIV

Light weight wall board or wall building block and manufacturing method thereof

InactiveCN1541971AIncrease molecular densityHigh strengthConstruction materialSolid waste managementHigh densityCompound (substance)

The material for light wall board and block consists of agricultural leftover, calcium increasing coal flyash, magnesium oxide, bentone and small amount of magnesium chloride and chemical preserving curing agent. The production process of light wall board and block includes the steps of: preparing agricultural leftover, calcium increasing coal flyash, magnesium oxide and bentone; compounding magnesium chloride aqua of Baume degree of 20-34; adding chemical preserving curing agent to the aqua via stirring; mixing prepared agricultural leftover, calcium increasing coal flyash, magnesium oxide and bentone with the solution; forming and natural curing. The advantages of the light wall board and block include high density, high strength, fireproofing, acid and alkali resistance, etc.

Owner:陈明轩

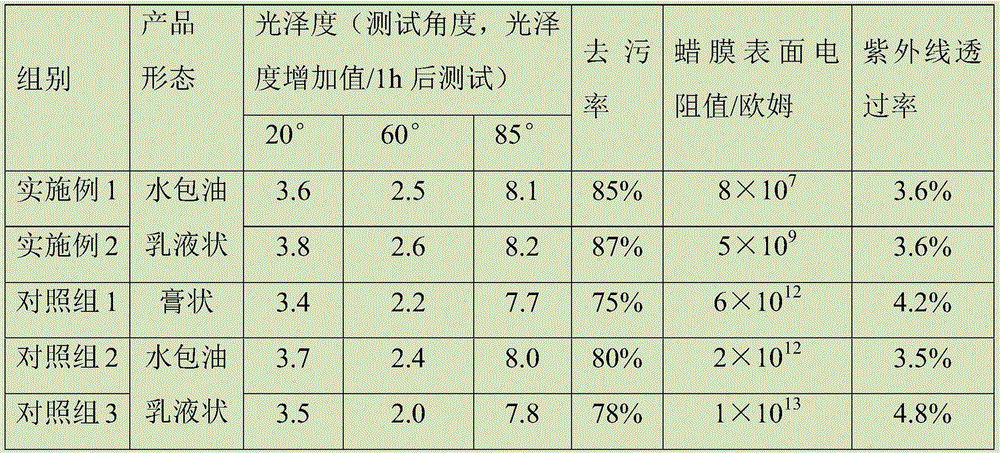

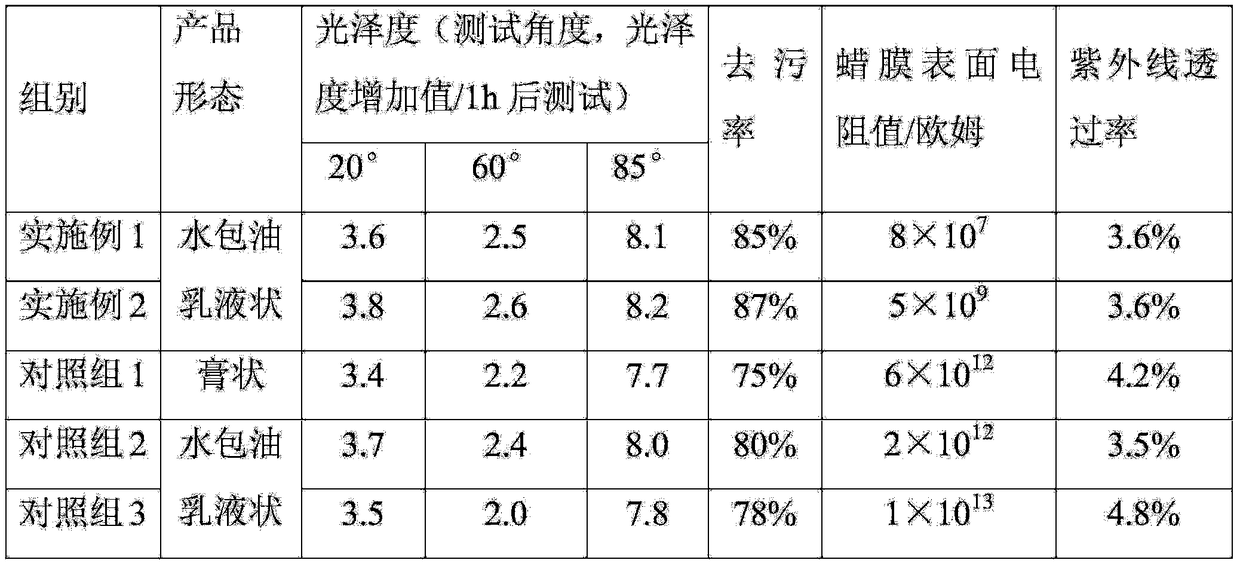

Cleaning and polishing integrated antistatic automobile polishing wax and preparation method thereof

ActiveCN106085247AHas the function of absorbing ultraviolet raysIncrease brightness functionInorganic/elemental detergent compounding agentsCationic surface-active compoundsEmulsionAntistatic agent

The invention relates to the field of polishing wax, and specifically relates to a cleaning and polishing integrated antistatic automobile polishing wax and a preparation method thereof. The cleaning and polishing integrated antistatic automobile polishing wax comprises, by mass, 1%-4% of an antistatic agent, 5%-10% of an emulsion, 25%-35% of a compound solution, 1%-2% of a brightener, 0.1%-0.3% of an ultraviolet absorbent, 0.1%-0.2% of a preservative, and 55%-65% deionized water. The antistatic agent is a polymer of sulfonated styrene and maleic acid or a sulfonated polystyrene polymer; the solute of the emulsion is a mixture of carnauba wax, paraffin, Fischer-Tropsch wax and an emulsifier, the solvent is the emulsifier, the mass fraction of the solute is 15%-20%, and in the solute, the carnauba wax, paraffin, and Fischer-Tropsch wax are in a mass ratio of 2:4:1-2:8:1. The automobile polishing wax provided by the invention integrates the functions of cleaning and dust removing, polishing, ultraviolet protection, static resistance, sterilizing and the like, and is convenient to use.

Owner:DONGGUAN UNIV OF TECH

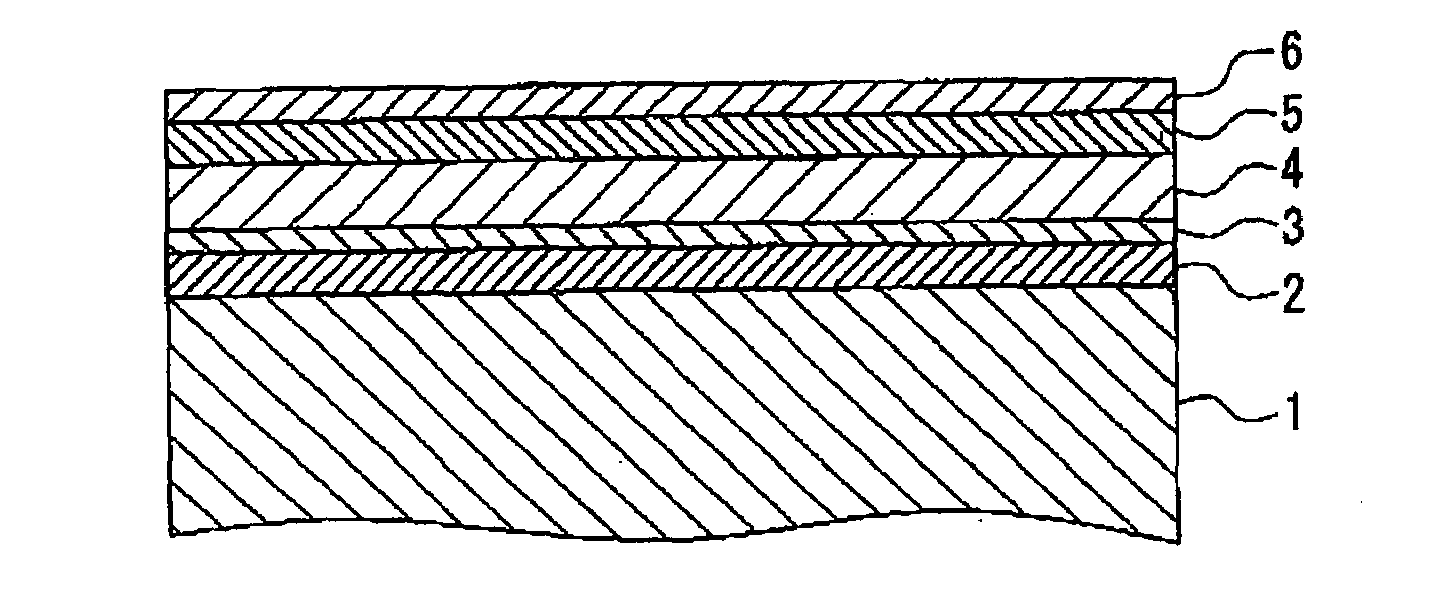

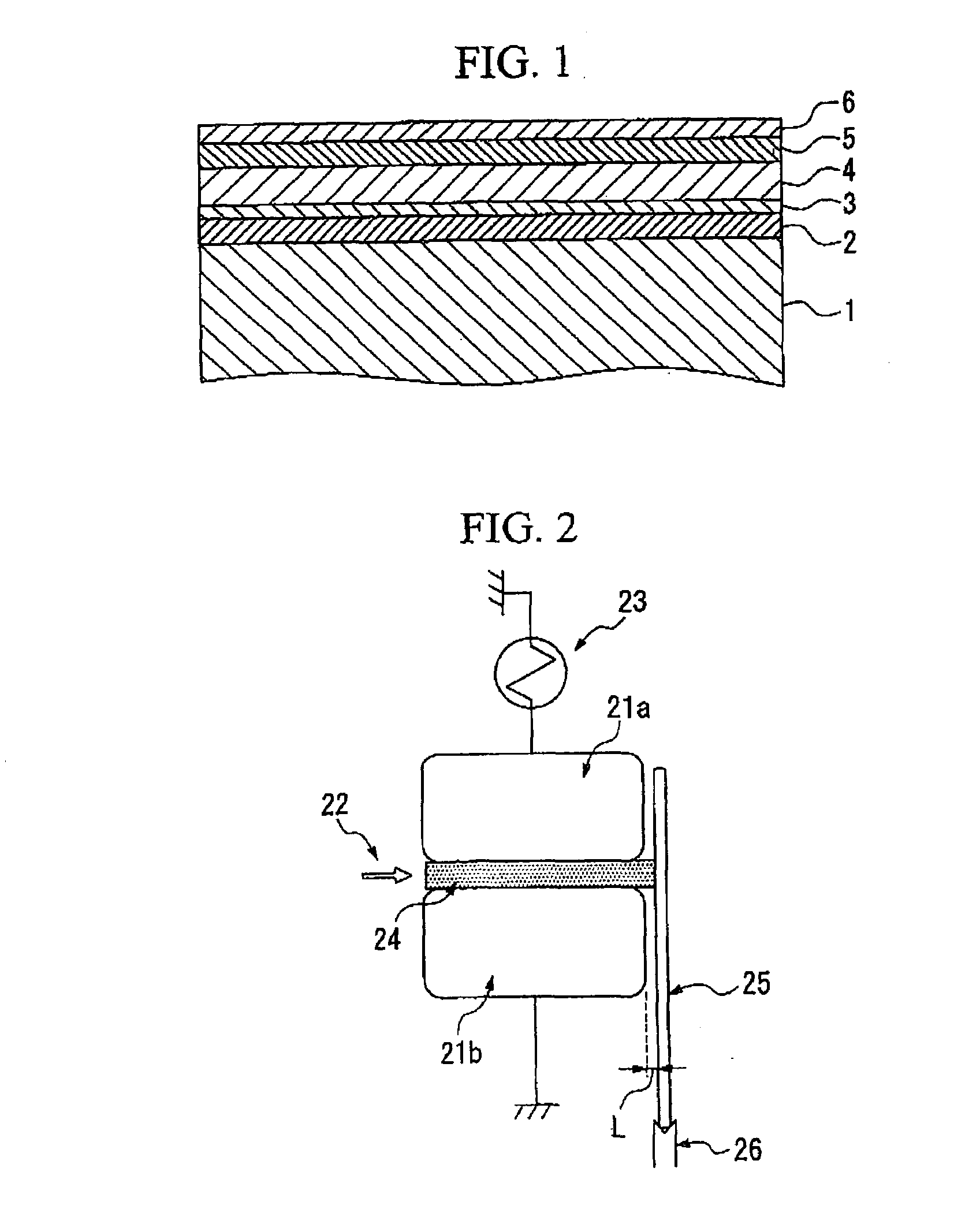

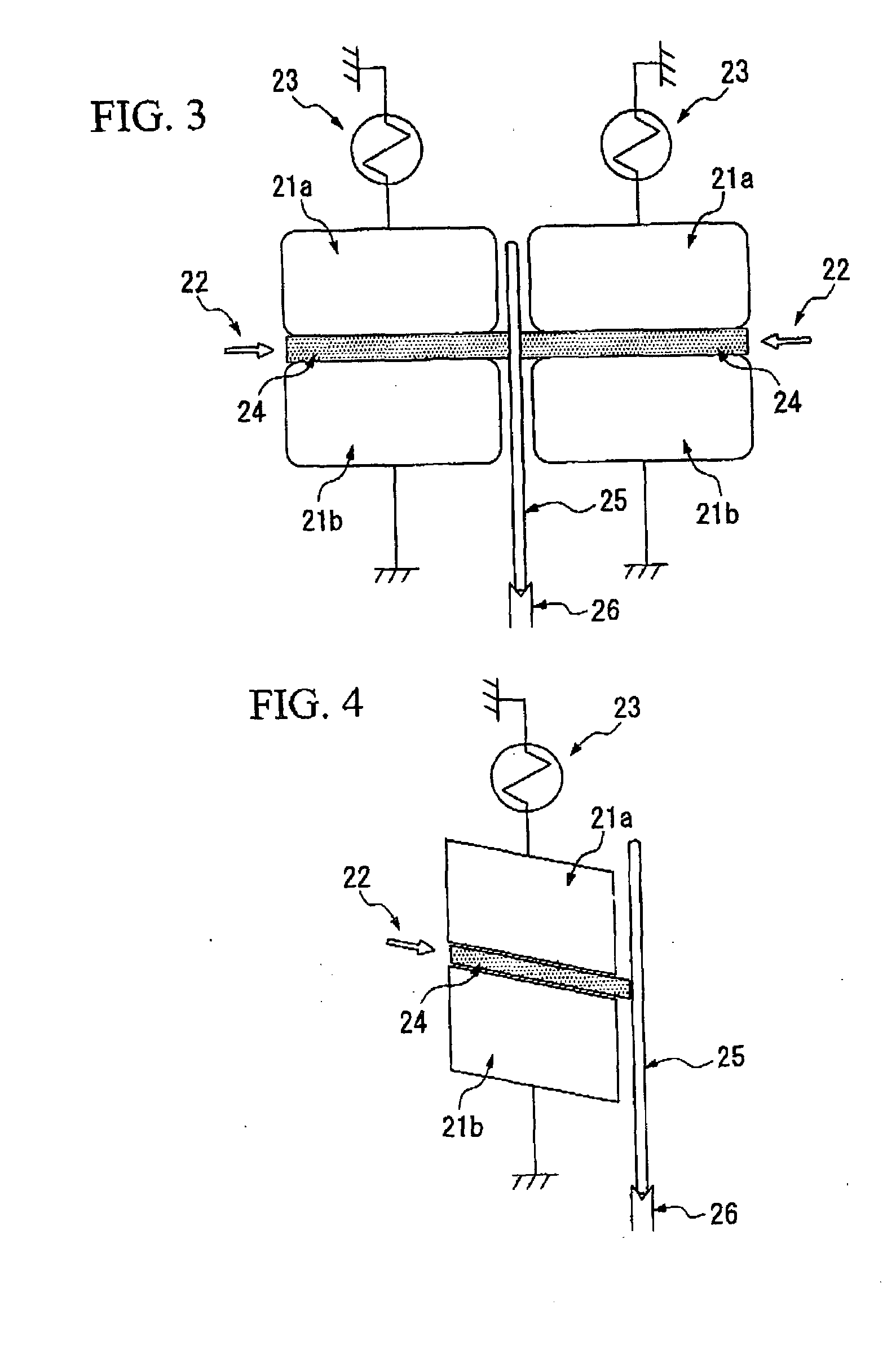

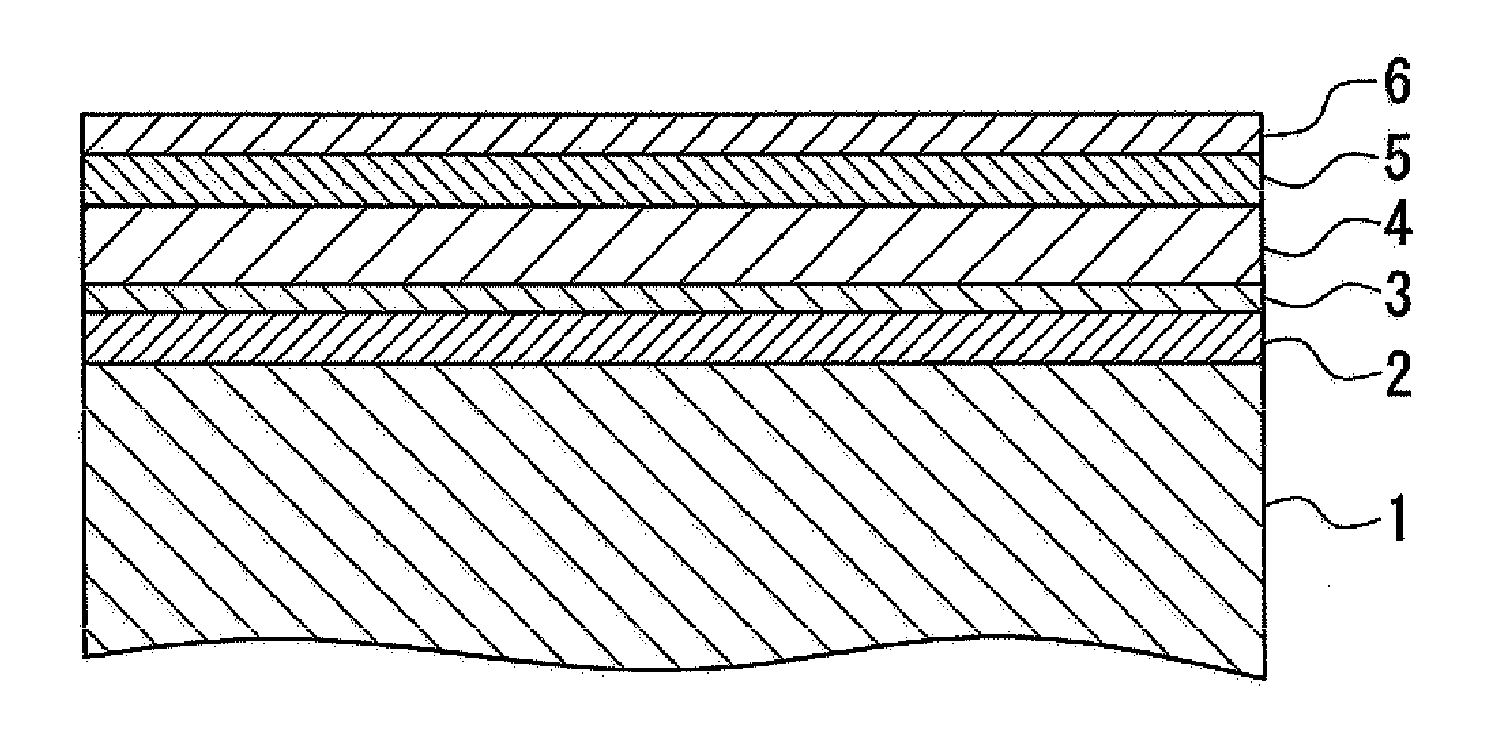

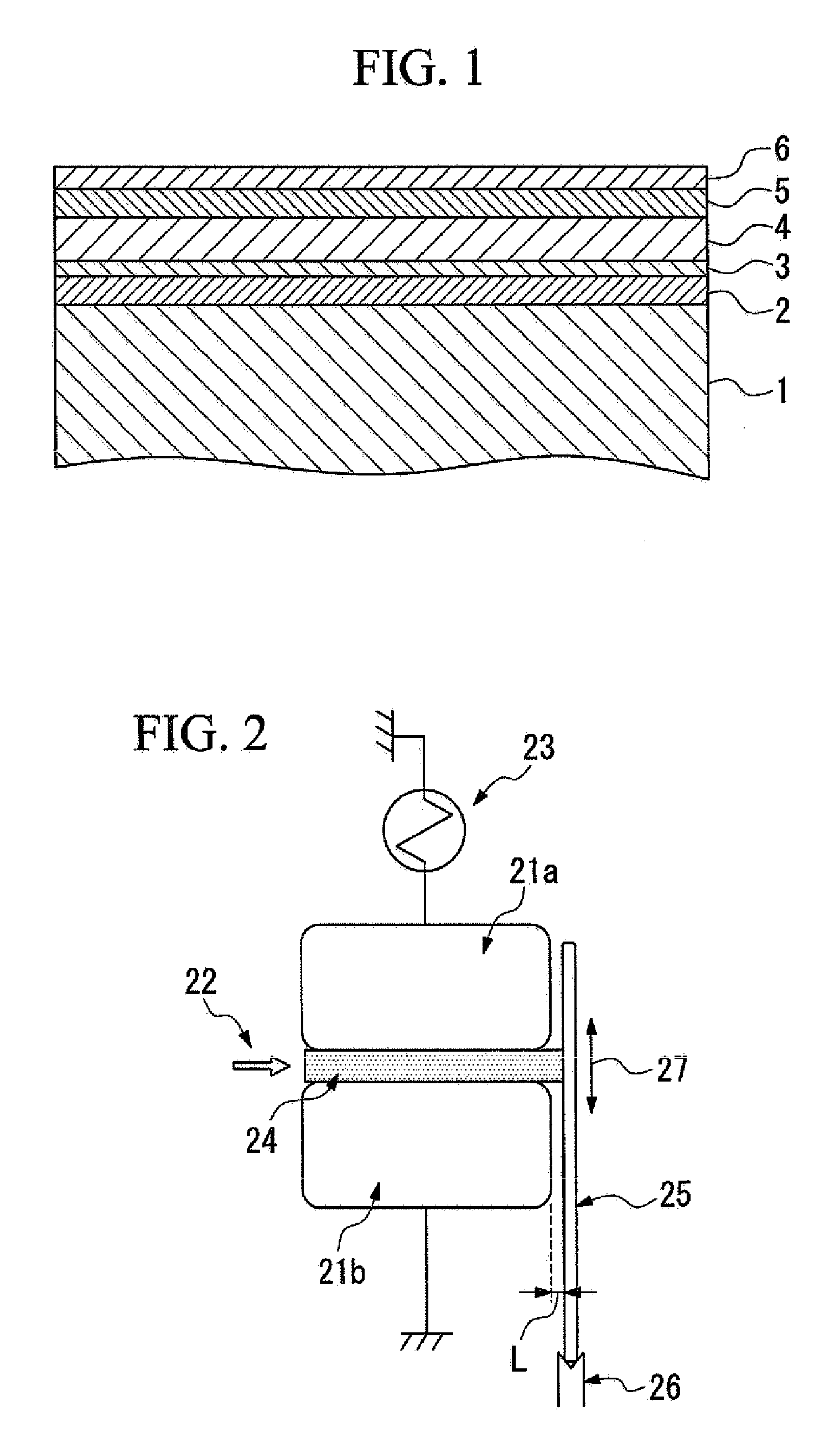

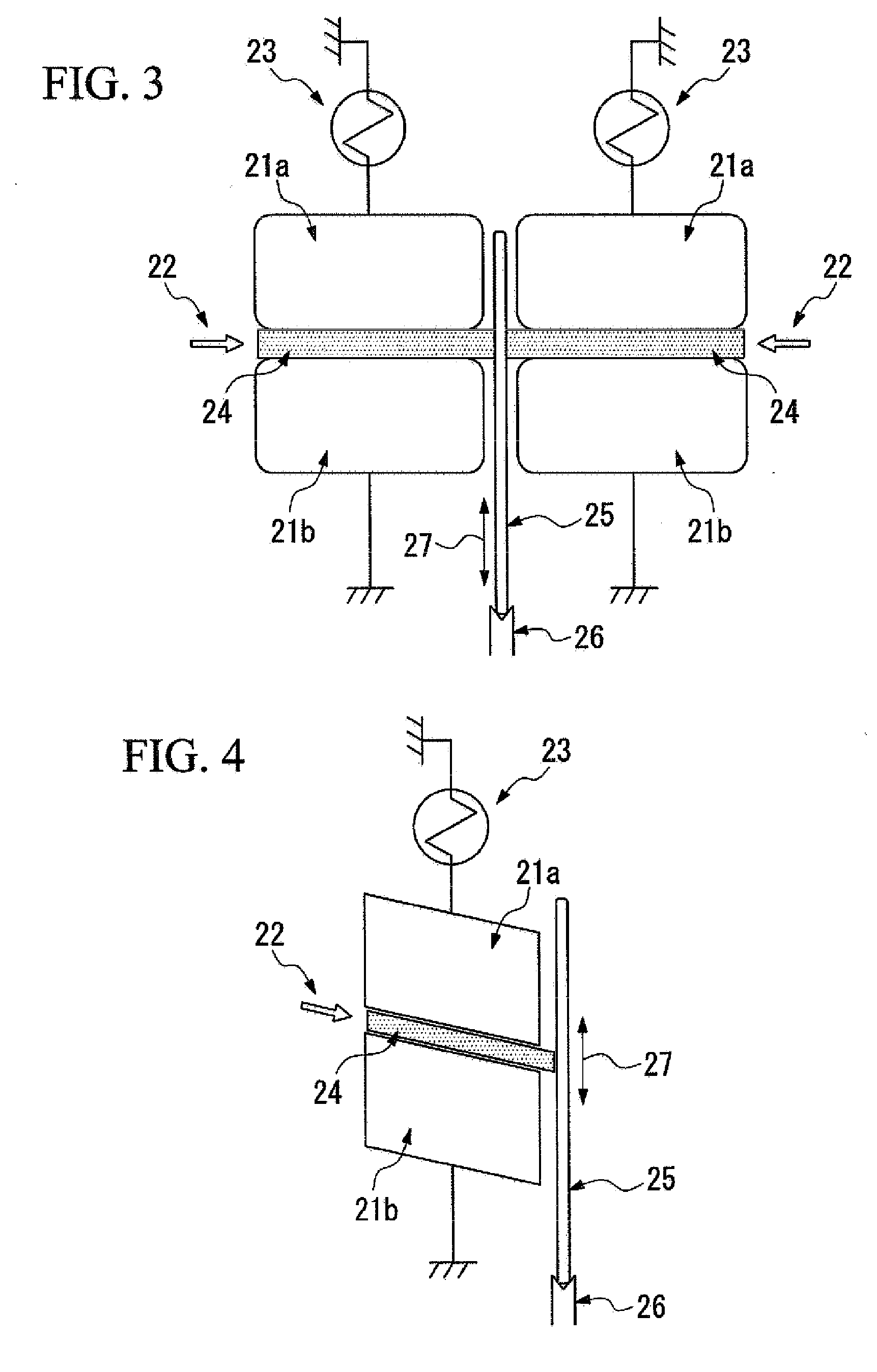

Magnetic Recording Medium and Production Process Thereof

InactiveUS20080310050A1High bonding strengthStatic friction coefficientMechanical working/deformationLamination ancillary operationsTectorial membraneEngineering

The present invention provides a magnetic recording medium having superior startup operation and durability as well as satisfactory surface lubricity. The present invention relates to a production process of a magnetic recording medium in which at least a magnetic layer, a protective film layer and a lubricant layer are sequentially laminated on a non-magnetic substrate, wherein the protective film layer is surface treated using a gas activated by plasma generated at a pressure in the vicinity of atmospheric pressure. The present invention also relates to a magnetic recording medium produced according to the aforementioned production process.

Owner:SHOWA DENKO KK

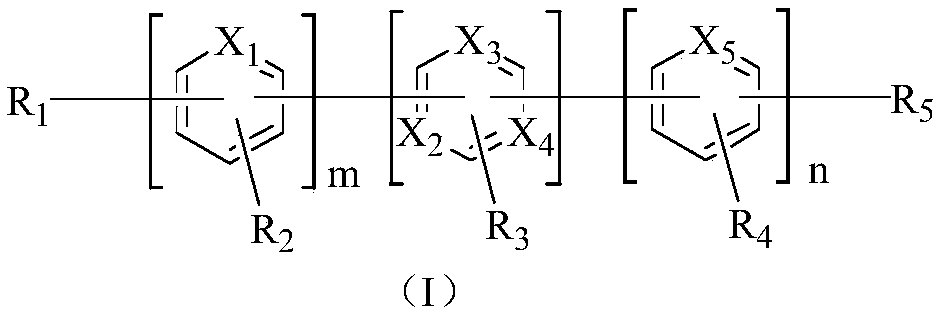

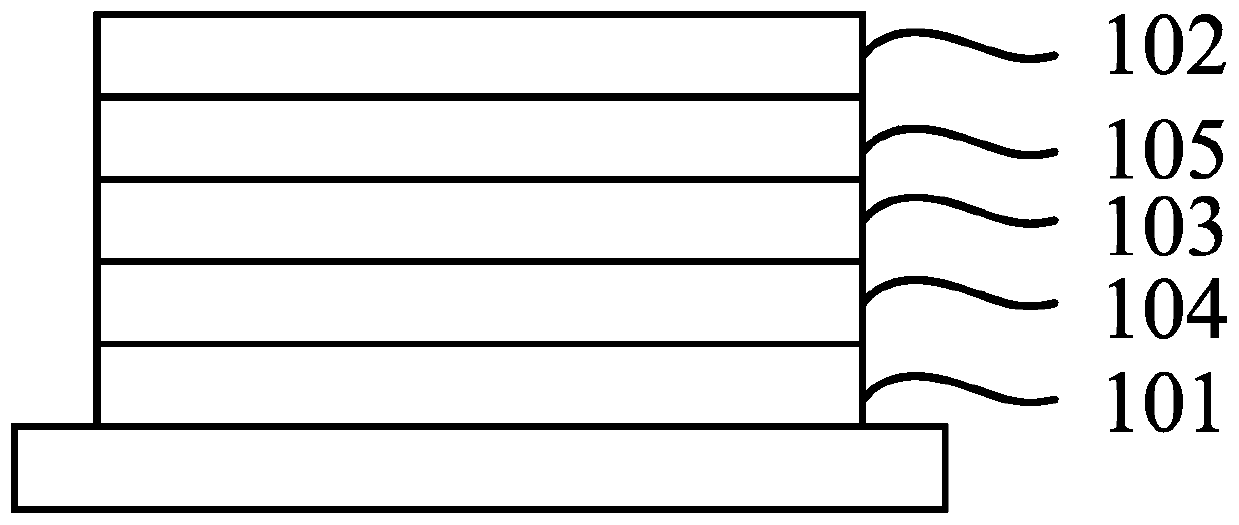

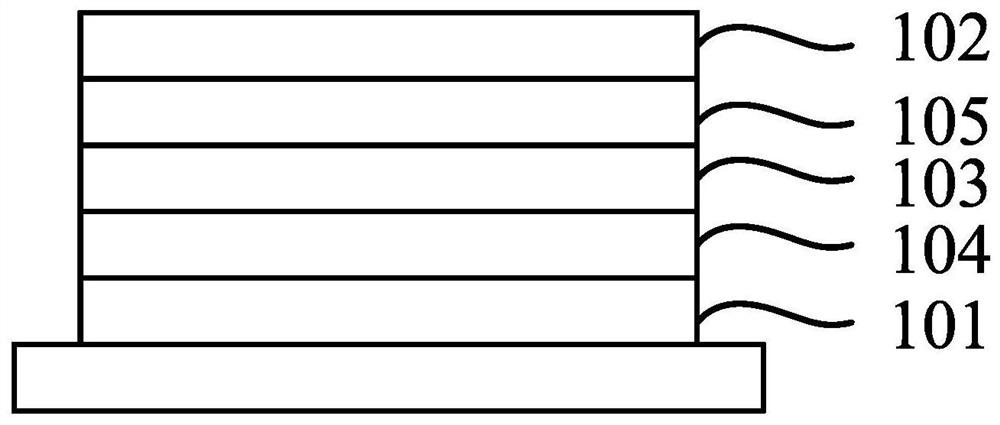

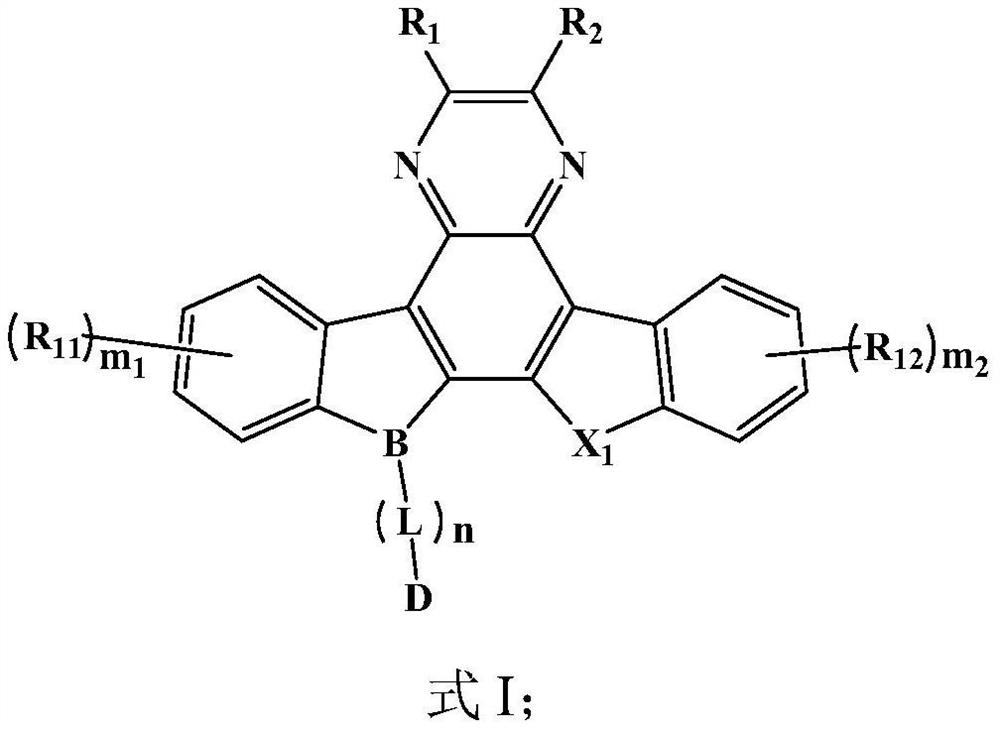

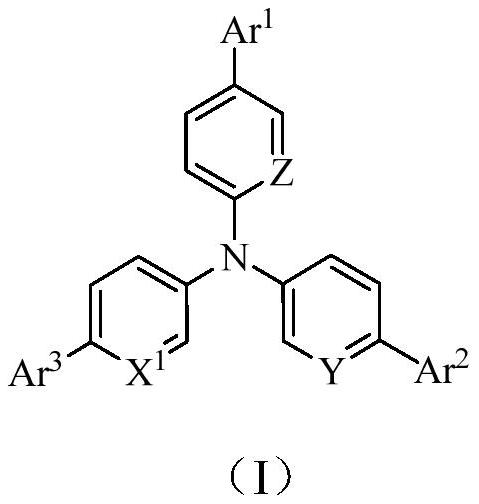

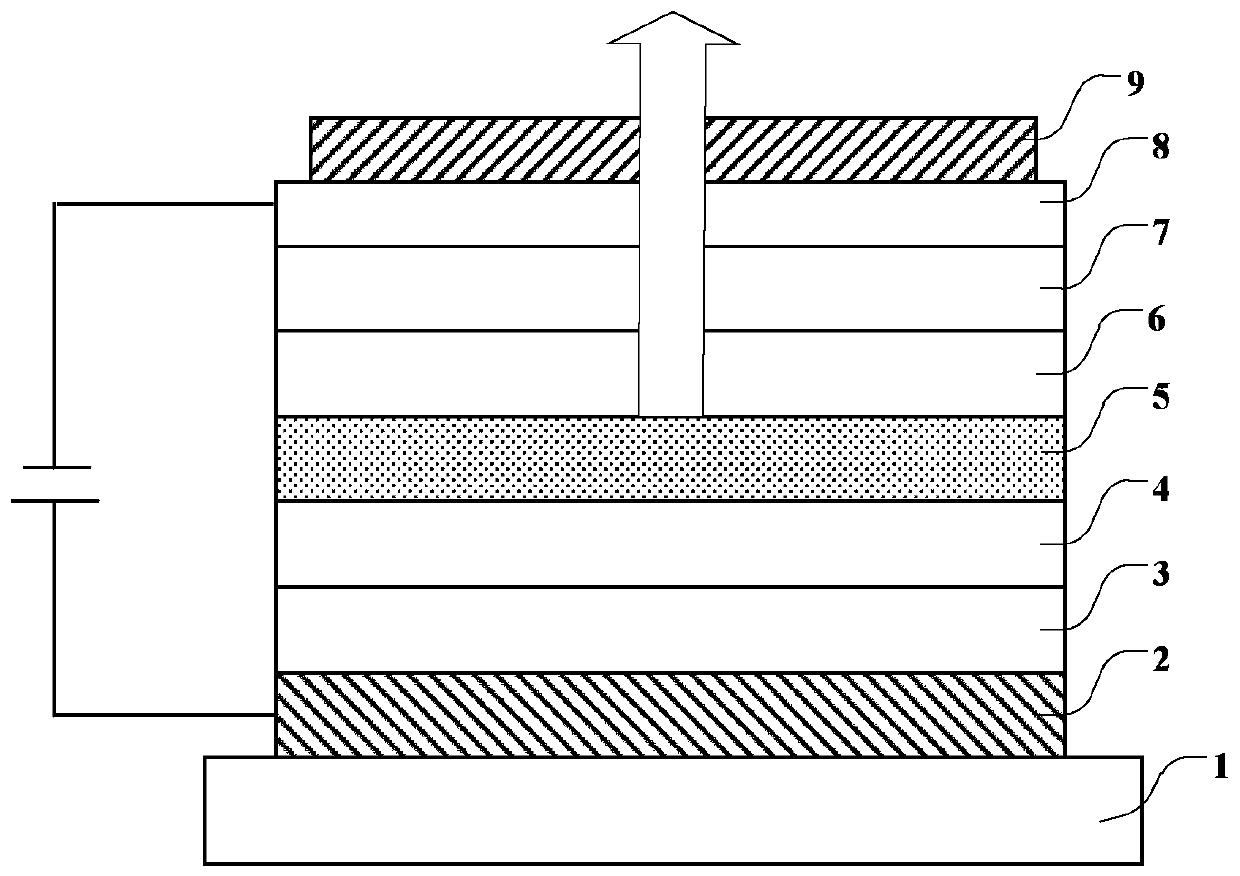

Nitrogen heterocyclic compound and organic light-emitting display device

ActiveCN108864054AImprove removal efficiencyImprove luminous efficiencyOrganic chemistrySolid-state devicesElectricityDisplay device

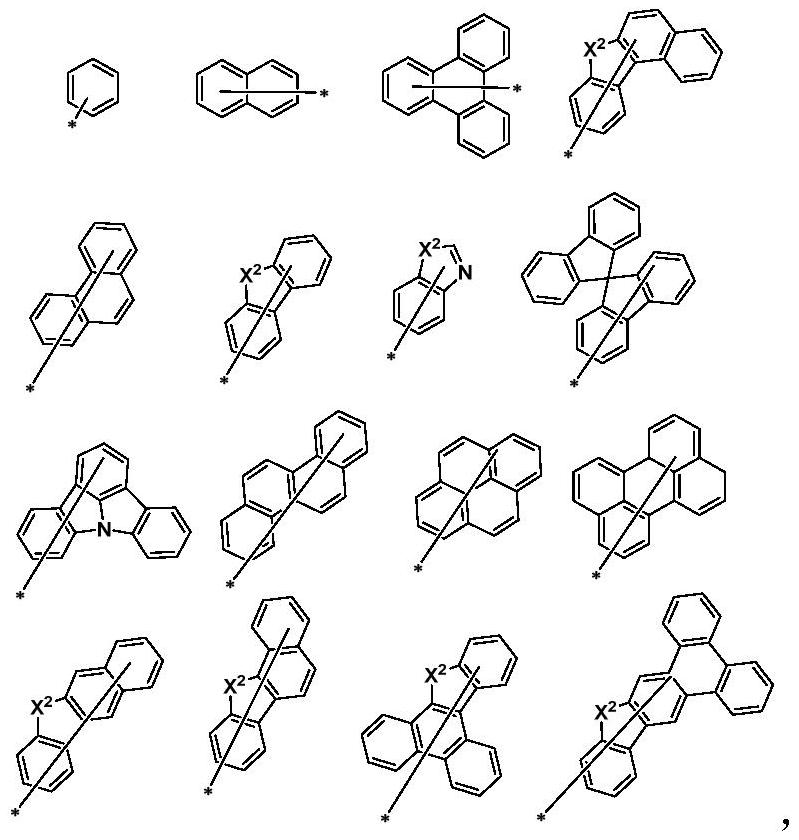

The invention relates to a nitrogen heterocyclic compound, which has a structure shown in a formula (I), wherein X1-X5 are C atoms or N atoms, and at least two of X2-X4 are N atoms; m and n are respectively and independently selected from 0, 1 or 2, and the sum of the m and the n greater than or equal to 1; R1-R5 are the same or different, and R1-R5 are respectively and independently selected fromsubstituted or unsubstituted C6-C60 aryls, substituted or unsubstituted C10-C60 fused aryls, substituted or unsubstituted C4-C60 five-membered heterocyclic rings, substituted or unsubstituted C6-C60six-membered heterocyclic rings. The nitrogen heterocyclic compound, as a main material or a CPL layer material in an electroluminescent device, has a higher triplet state energy level ET and a largermolecular density as well as higher glass transition temperature and molecular thermal stability, effectively improves the balanced migration of carriers, widens an exciton recombination region, effectively improves the light extraction efficiency, and greatly improves the luminous efficiency and service life of the device, thus being better applied in the technical field of electroluminescent devices. The invention also provides an organic light emitting display device.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD

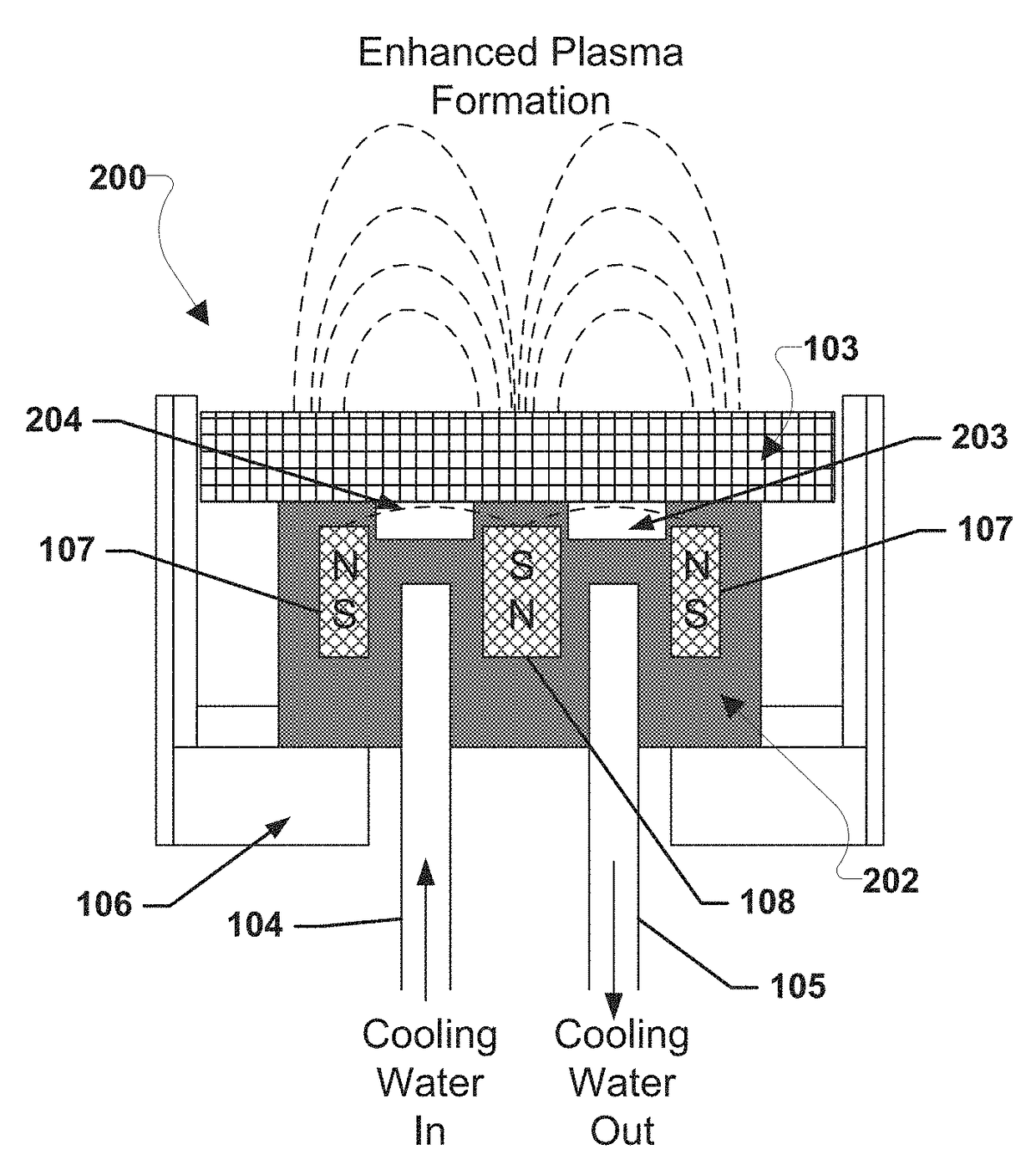

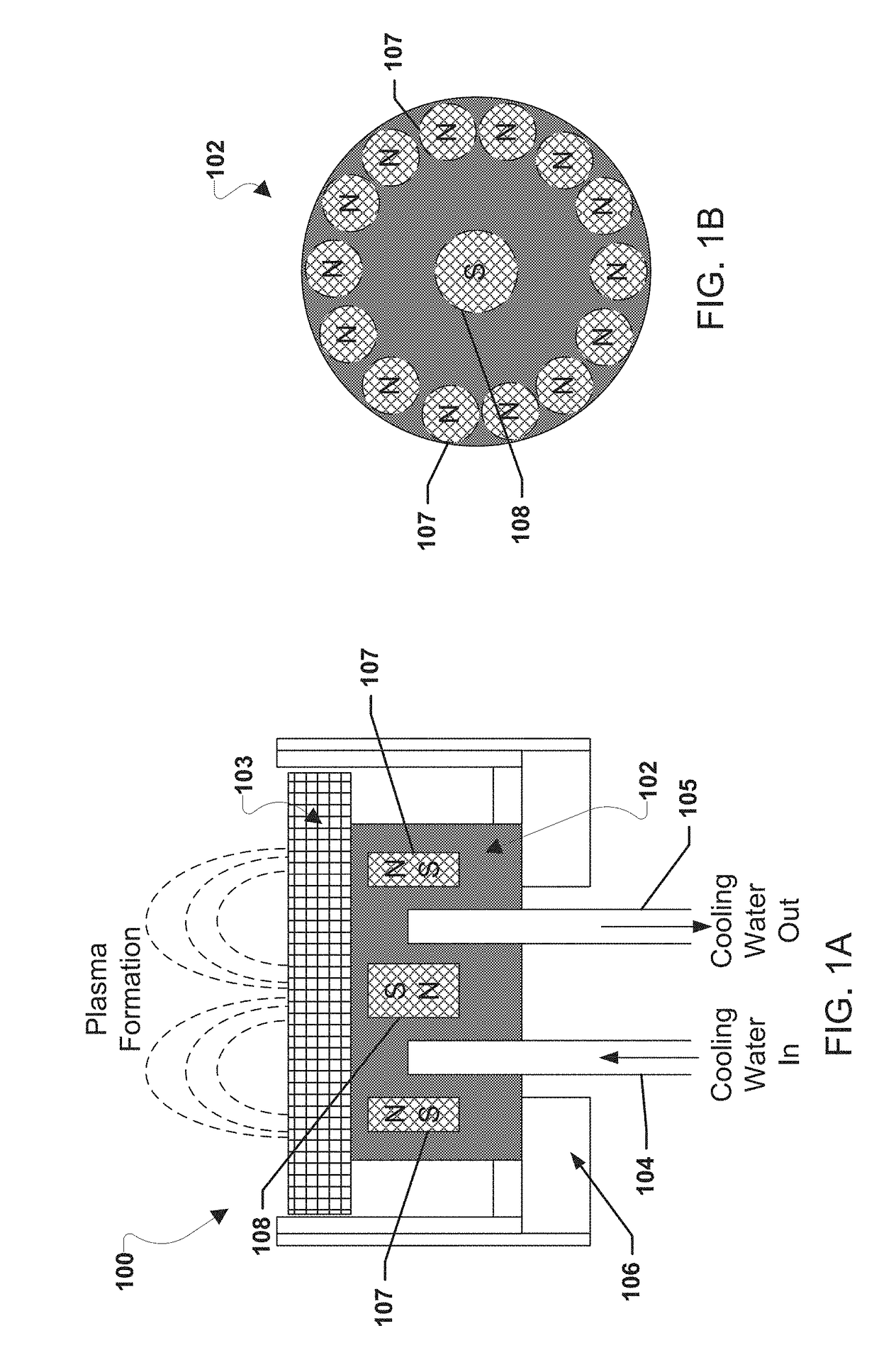

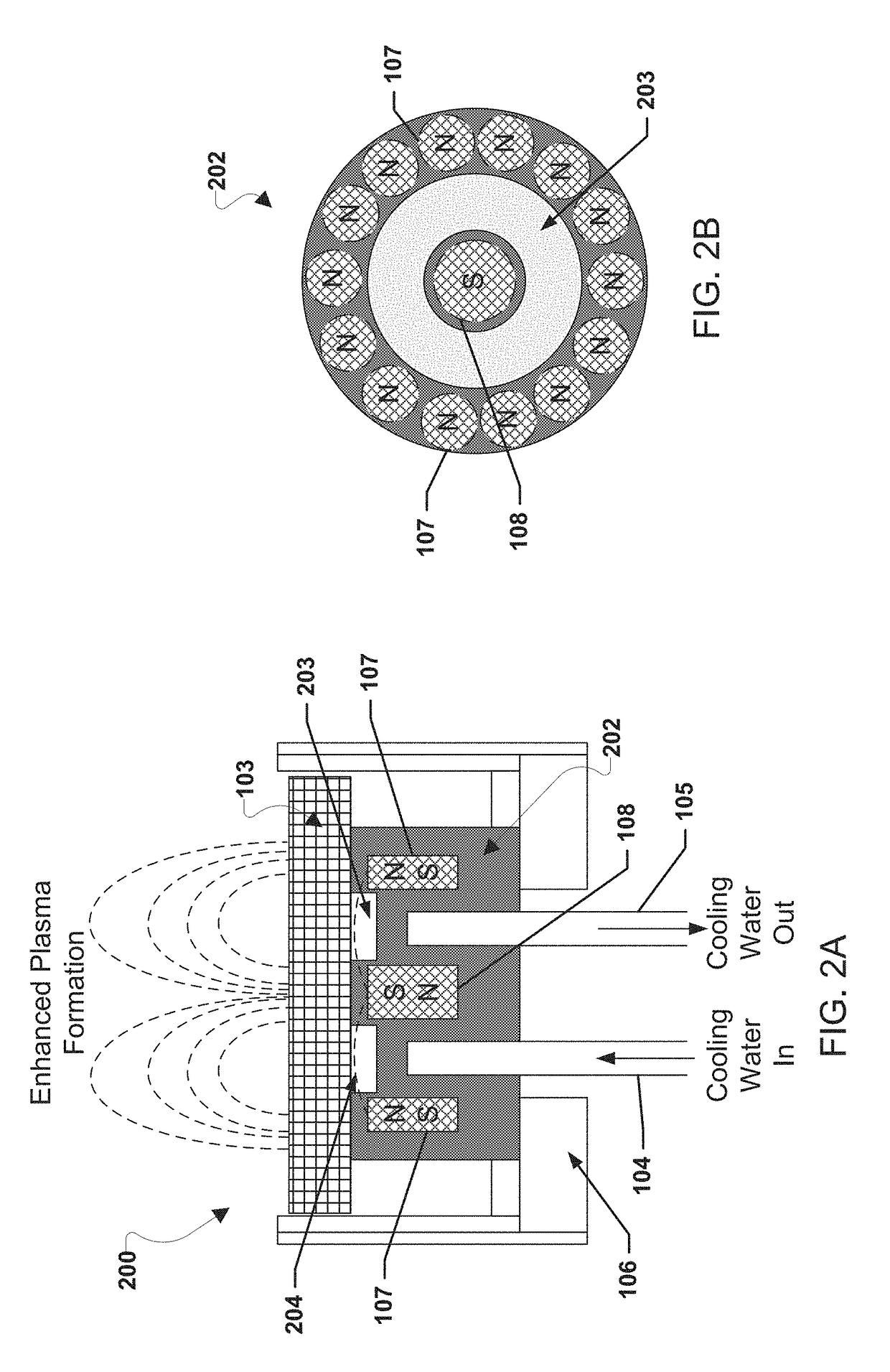

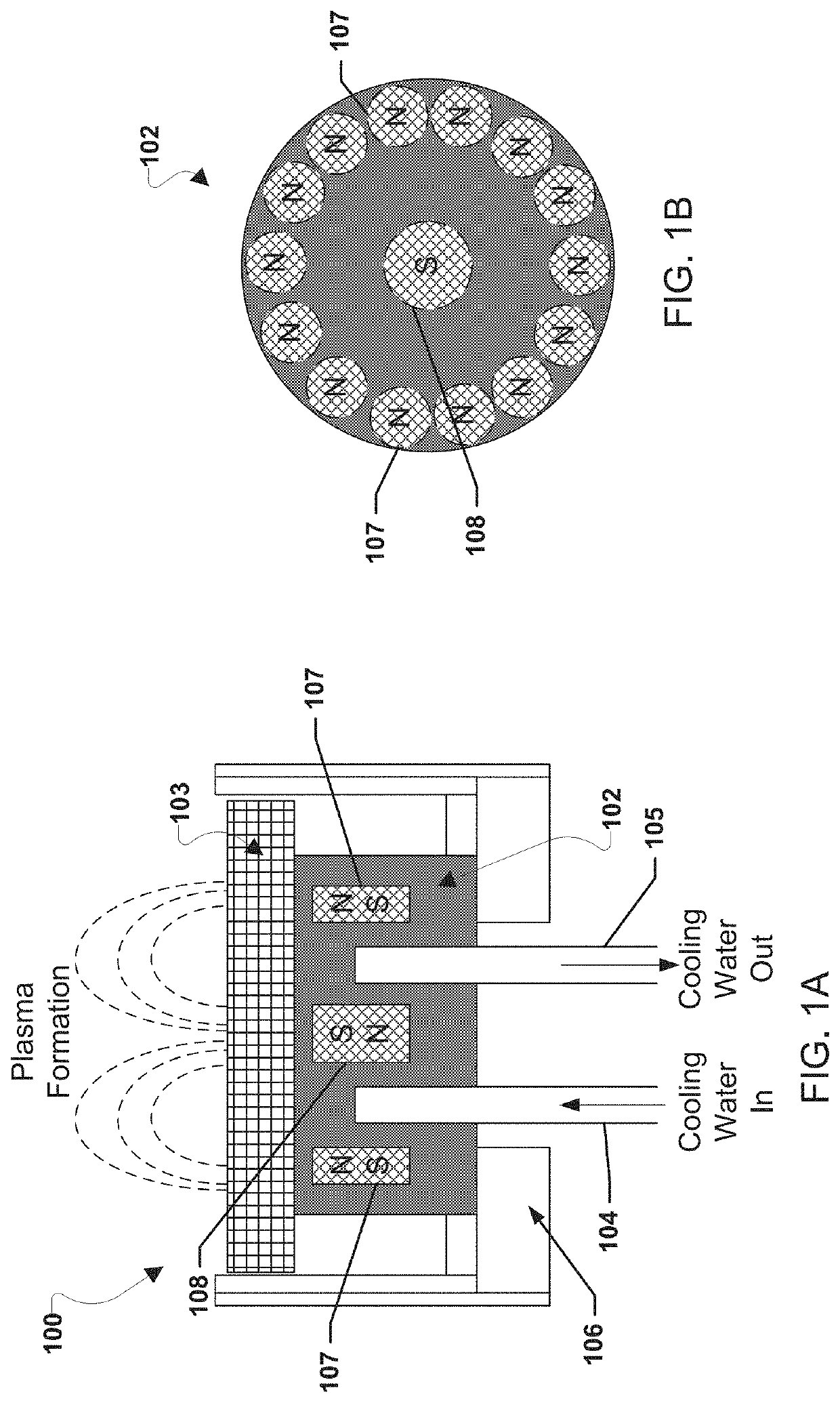

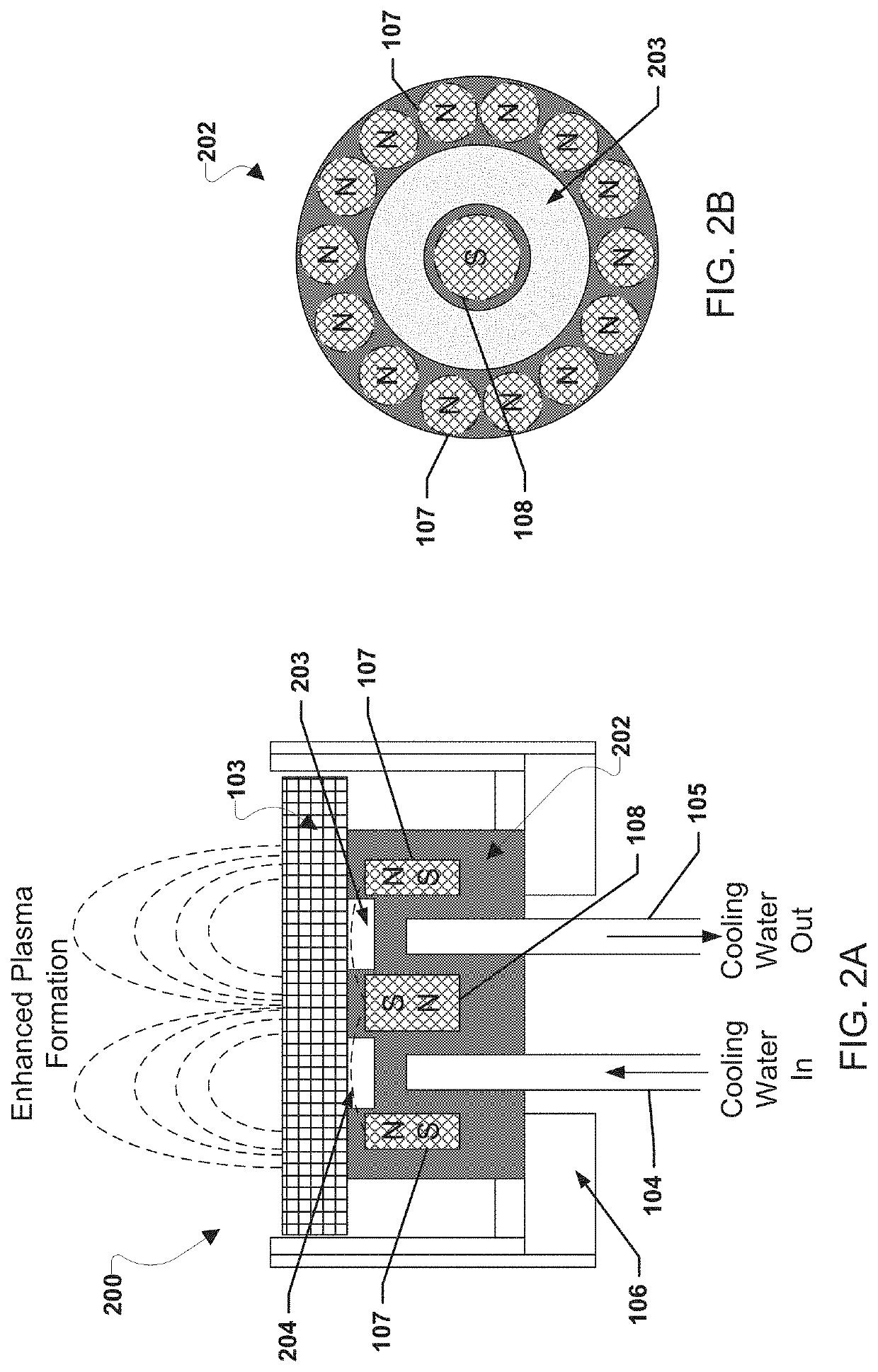

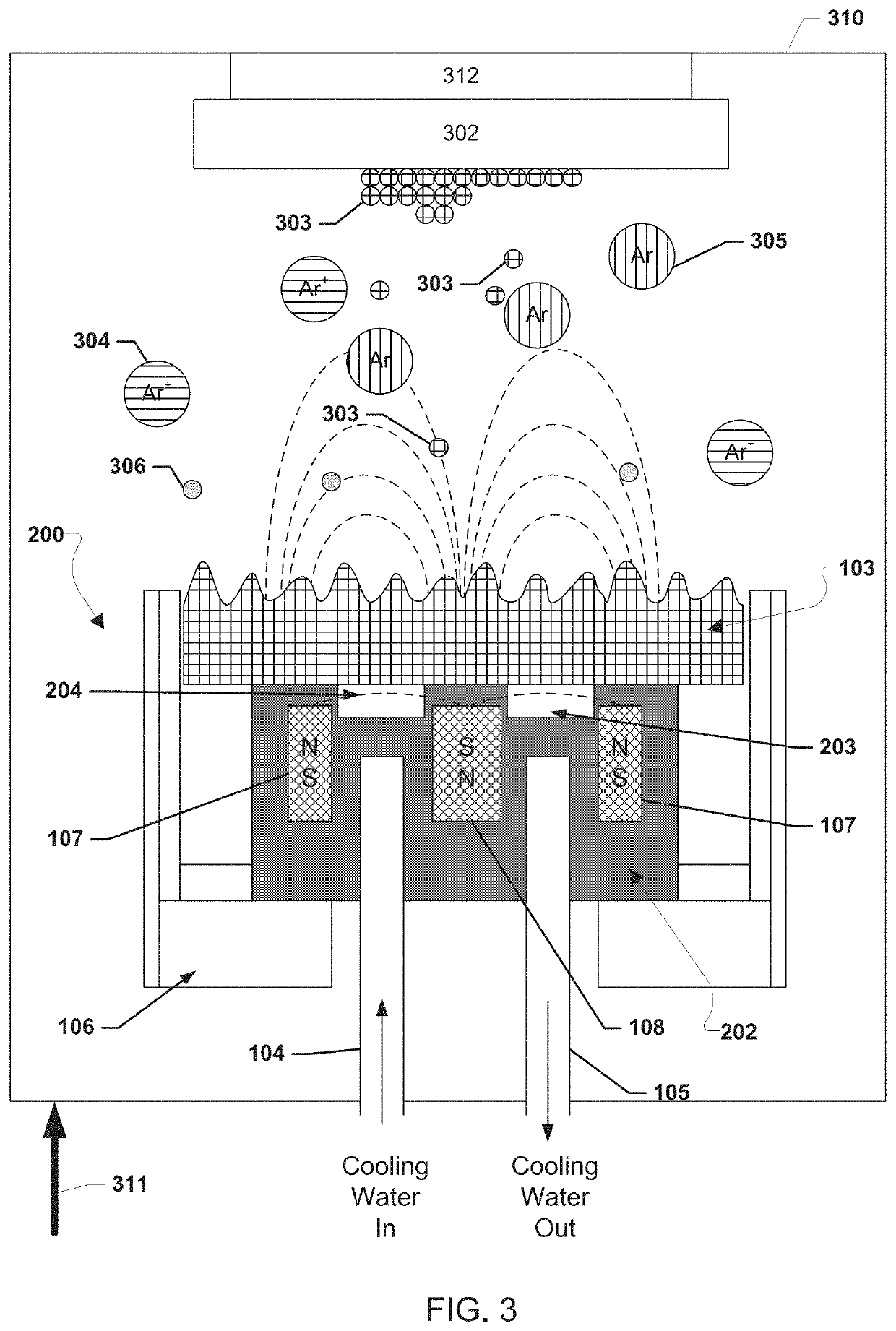

Molten Target Sputtering (MTS) Deposition for Enhanced Kinetic Energy and Flux of Ionized Atoms

ActiveUS20170268122A1Increase kinetic energyFaster crystal formationPolycrystalline material growthElectric discharge tubesSputteringSingle crystal

Various embodiments provide Molten Target Sputtering (MTS) methods and devices. The various embodiments may provide increases in the kinetic energy, increases in the energy latency, and / or increases in the flux density of molecules for better crystal formation at low temperature operation. The various embodiment MTS methods and devices may enable the growth of a single crystal Si1-xGex film on a substrate heated to less than about 500° C. The various embodiment MTS methods and devices may provide increases in the kinetic energy, increases in the energy latency, and / or increases in the flux density of molecules without requiring the addition of extra systems.

Owner:NASA

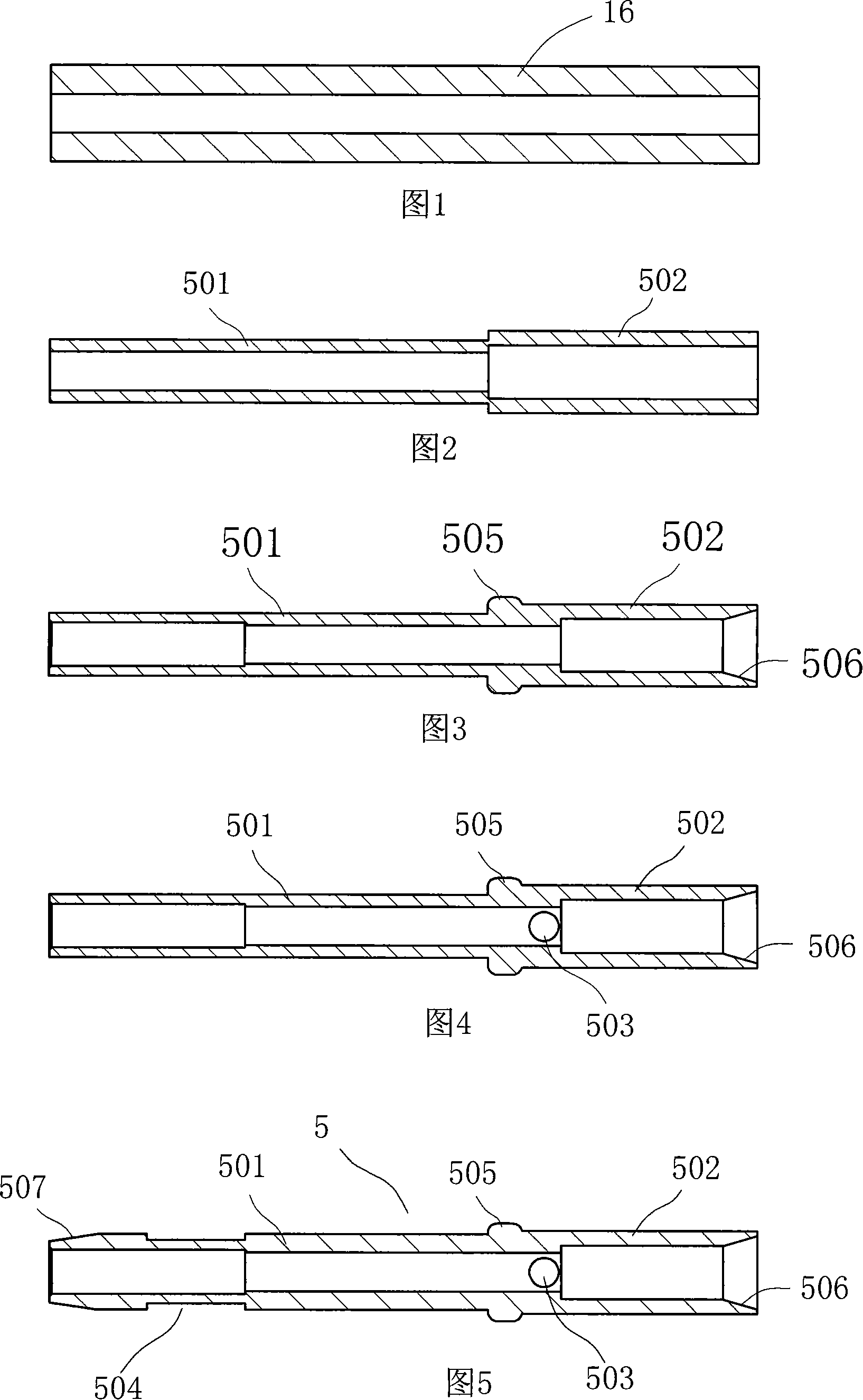

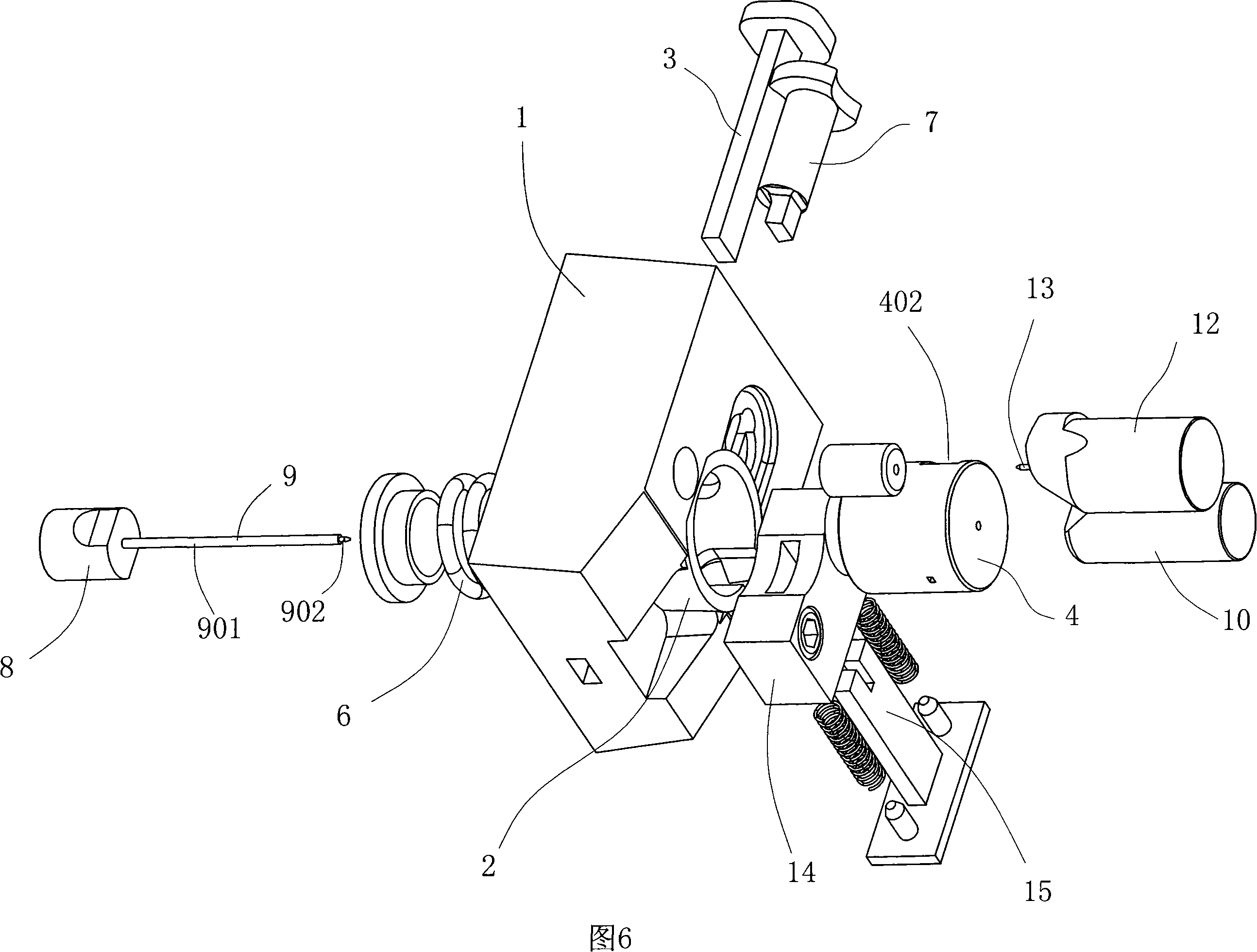

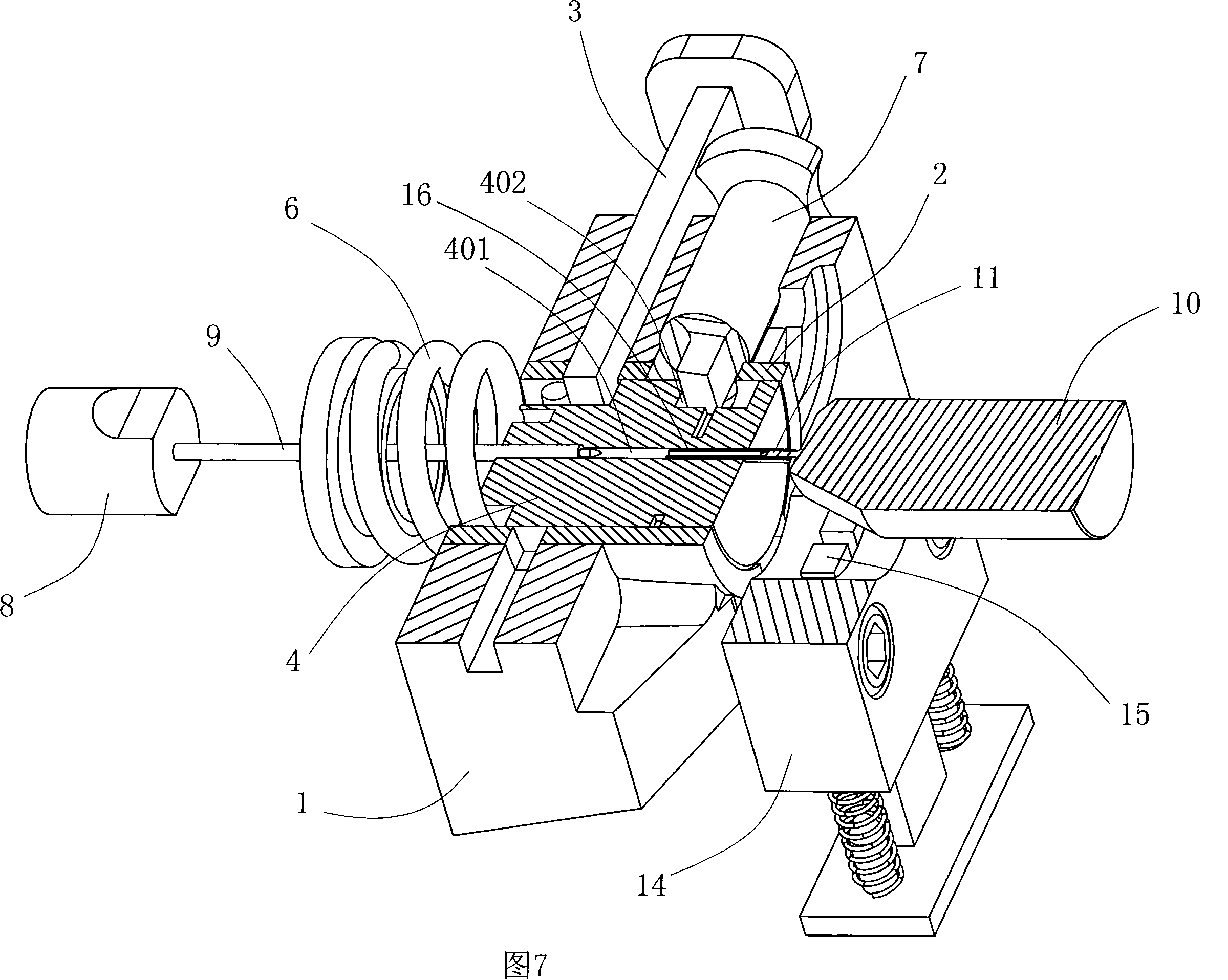

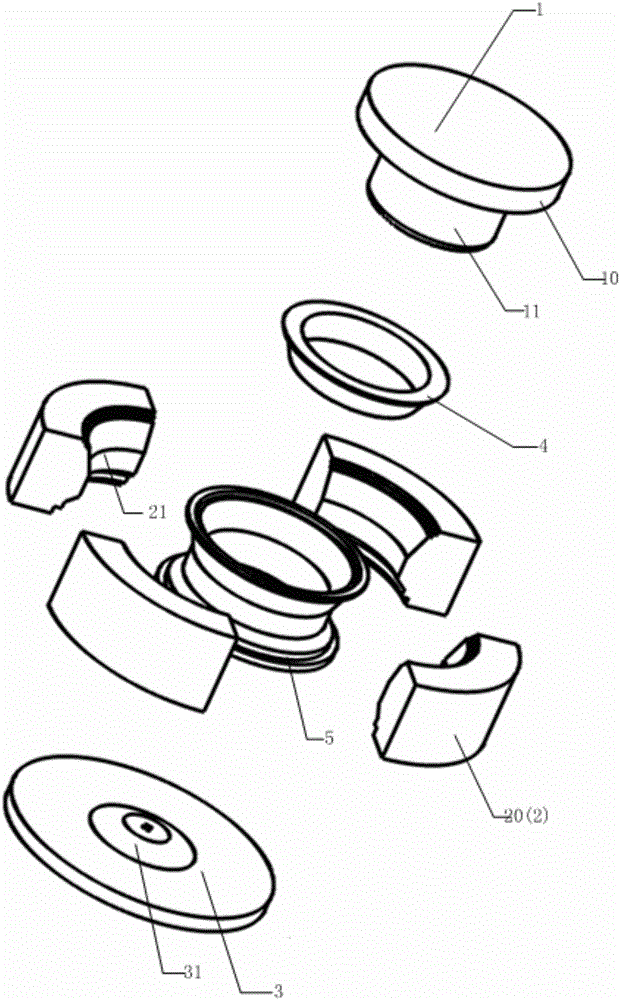

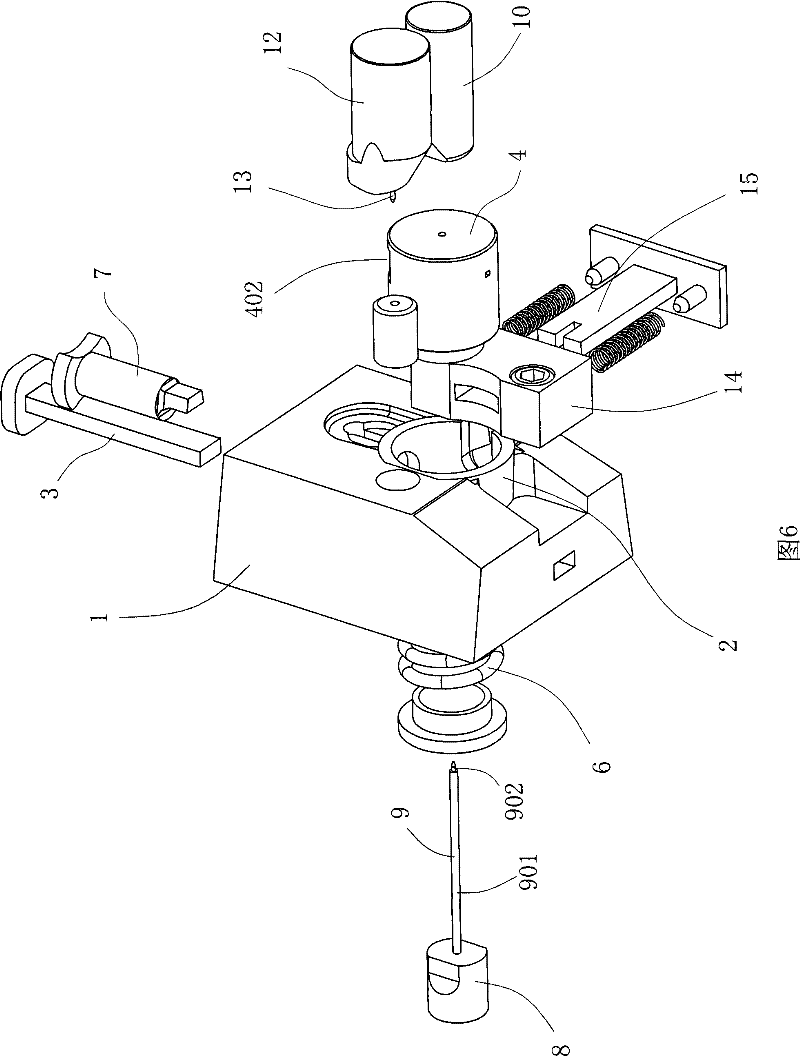

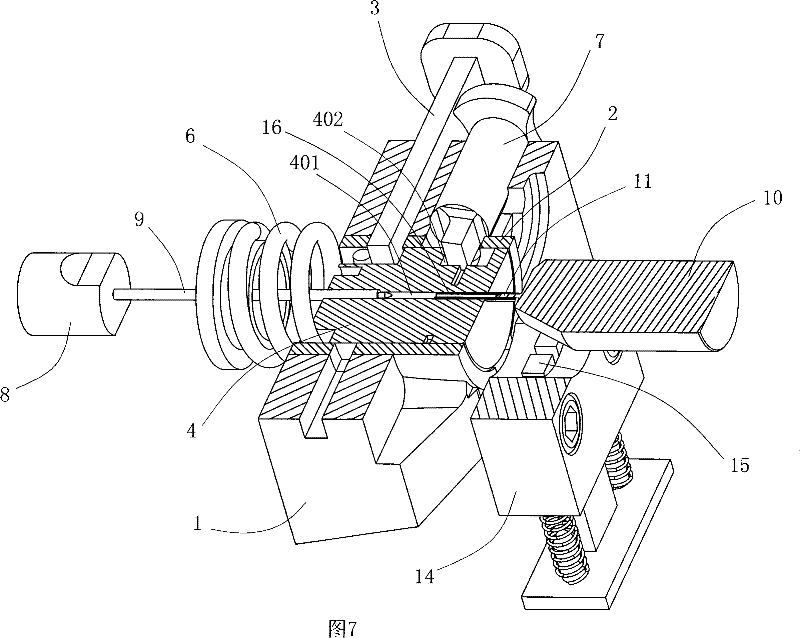

Cigarette lighter nozzle manufacture method and mould for the method

The invention discloses a lighter nozzle manufacturing method and a mould for the method. The manufacturing method is supported with low carbon steel tubes as raw materials; the invention comprises such steps as cutting, cold heading, horizontal hole-punching and catwalk slot machining and etc. The mould, however, comprises a support, a first mould, a resetting spring, a first staple, a second mould, a third mould and a fourth mould; the first mould is assembled inside a through-hole in the support; the interior is opened with the first through-hole in the consistent external diameter as that of the front of the end-product nozzle; the second mould is composed of the second thimble fitting with the first through-hole, so as to form the front part of the nozzle; the fourth mould inside is composed of an aperture in an identical external diameter as that of the rear of the end-product nozzle; the aperture inside is provided with the fourth thimble, in order to form the rear part and the shoulder on the nozzle. The invention method has the advantages of simple technologies, high production efficiency, low raw-material cost and manufacturing expenses, and low consumption of materials and etc; the mould has the advantages of simple structure and convenient use, and therefore, in particular adapting to the manufacturing of lighter nozzles.

Owner:徐伟明

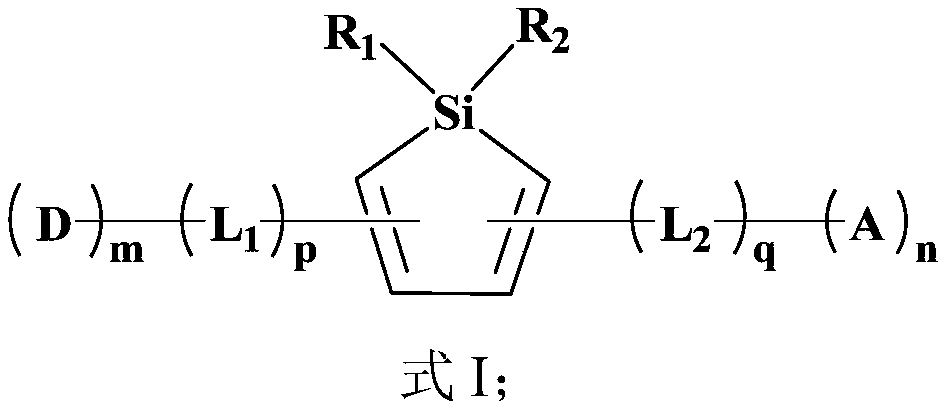

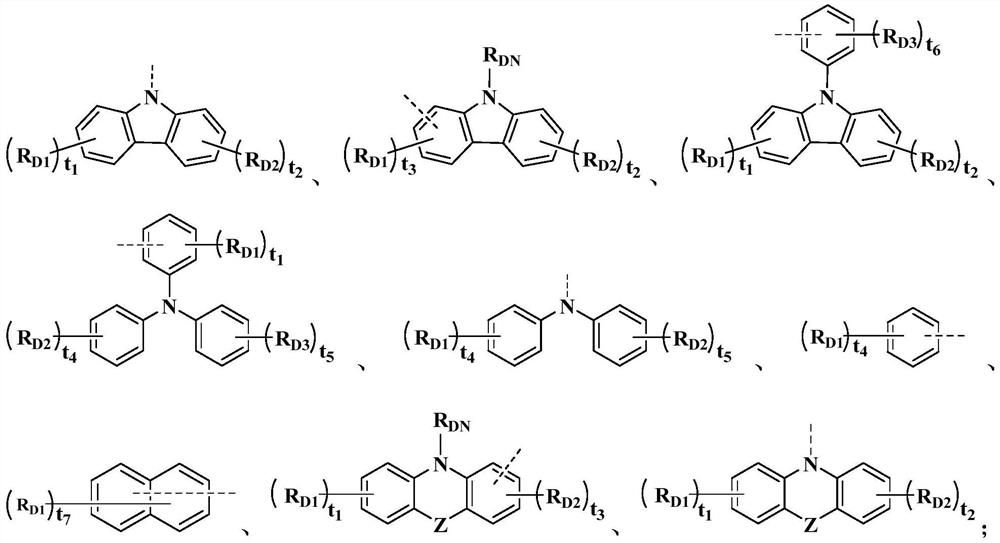

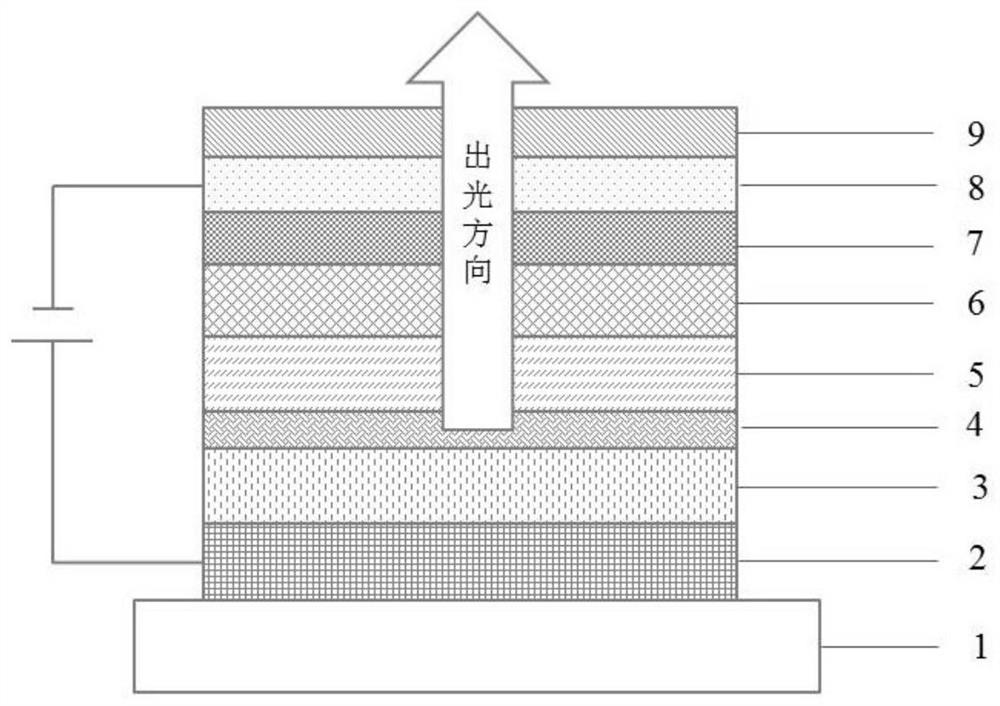

Organic electroluminescent compound and application thereof

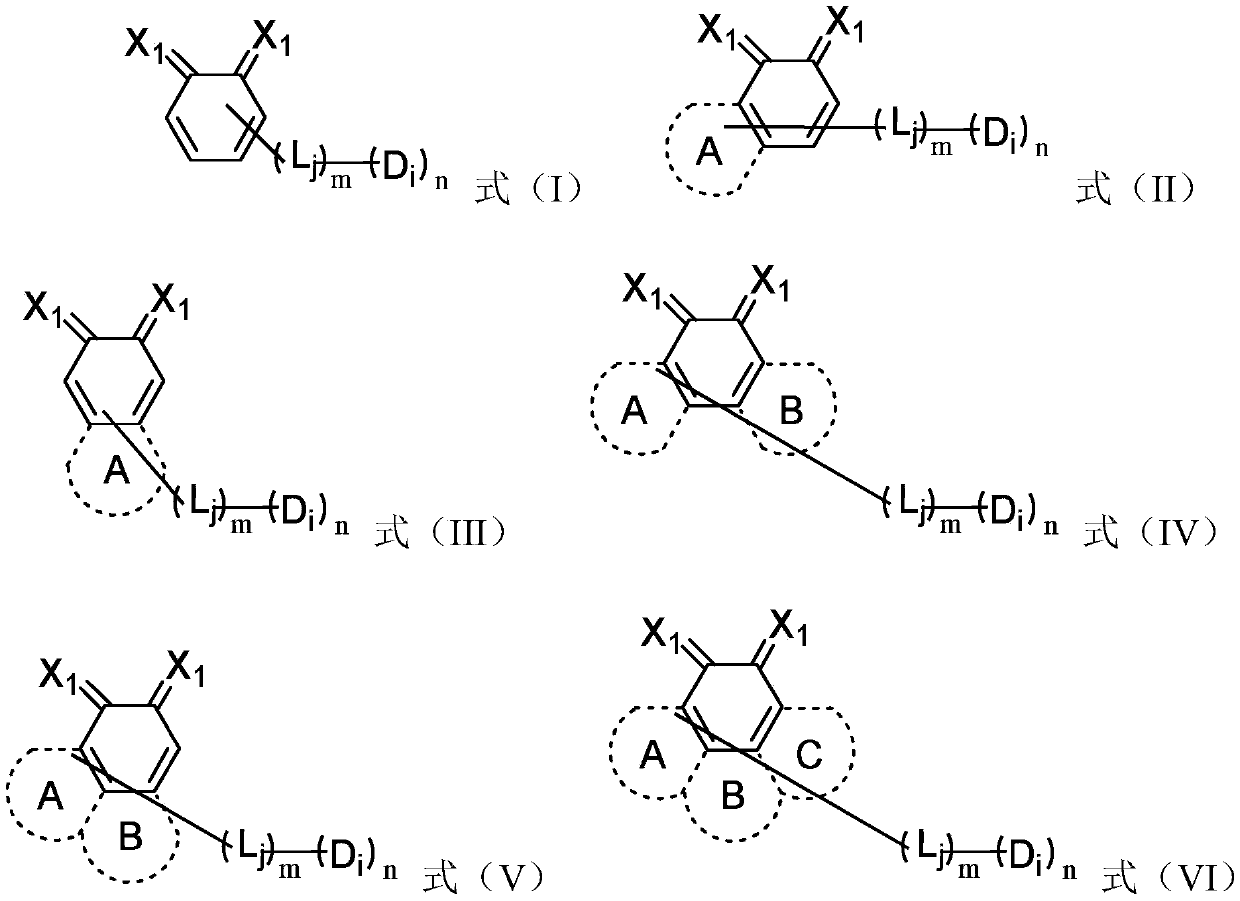

ActiveCN110590827AGood electron affinityGood electron mobilitySilicon organic compoundsGroup 5/15 element organic compoundsOrganic electroluminescenceOrganic compound

The invention provides an organic electroluminescent compound and application thereof. The organic electroluminescent compound has a structure as shown in formula I and is a novel bipolar light-emitting organic compound. The organic electroluminescent material can be used as a light-emitting layer material of an organic electroluminescent device comprising an anode, a cathode, and at least one organic thin film layer between the anode and the cathode, and the light-emitting layer of the organic thin film layer comprises any one or a combination of at least two of the organic electroluminescentcompounds. The organic electroluminescent compound provided by the invention has high triplet energy level ET, large molecular density, high glass transition temperature and molecular thermal stability; balanced migration of carriers is improved effectively; an exciton recombination area is widened; the light extraction efficiency is improved; and the luminous efficiency of an organic electroluminescent device is greatly improved, the service life of the organic electroluminescent device is greatly prolonged, and the application prospect is wide.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD

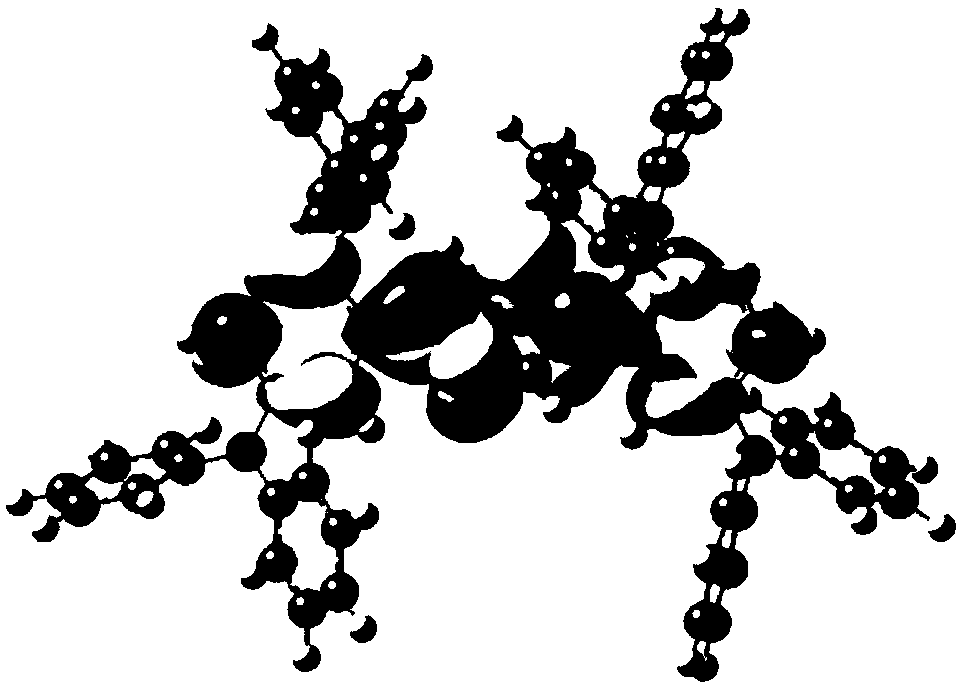

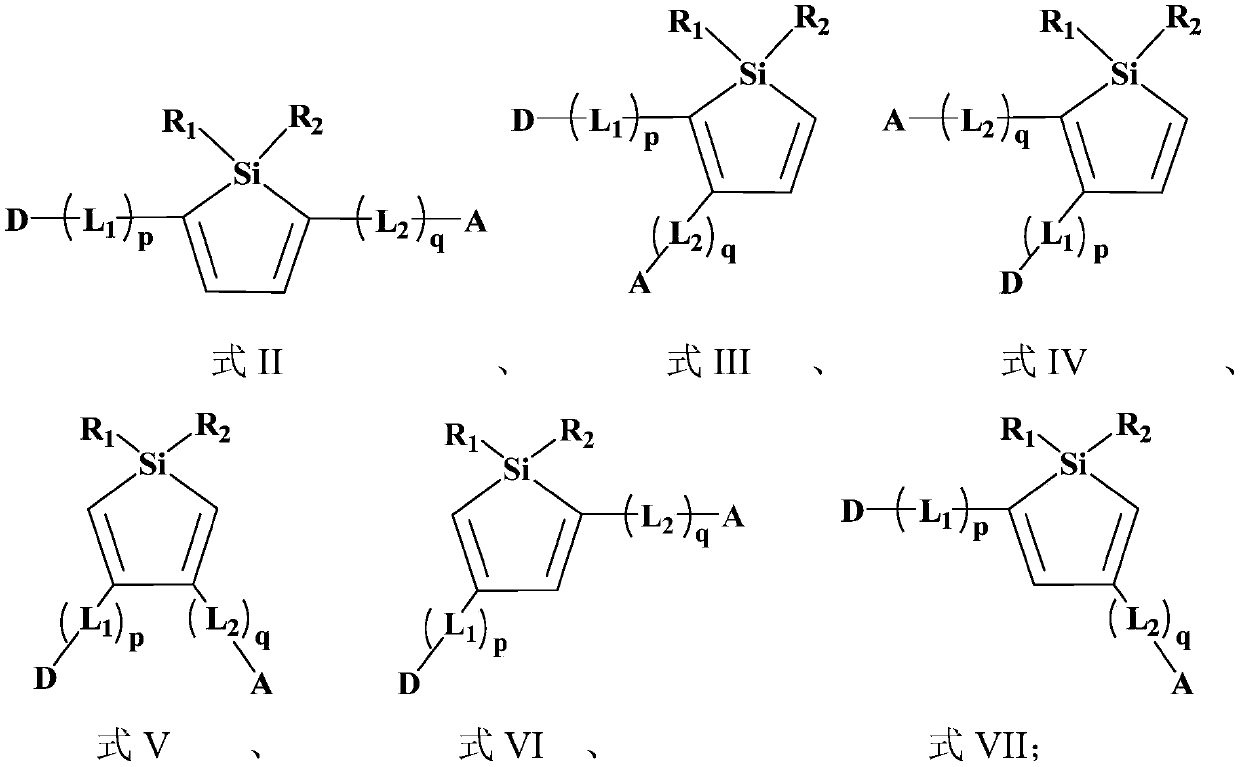

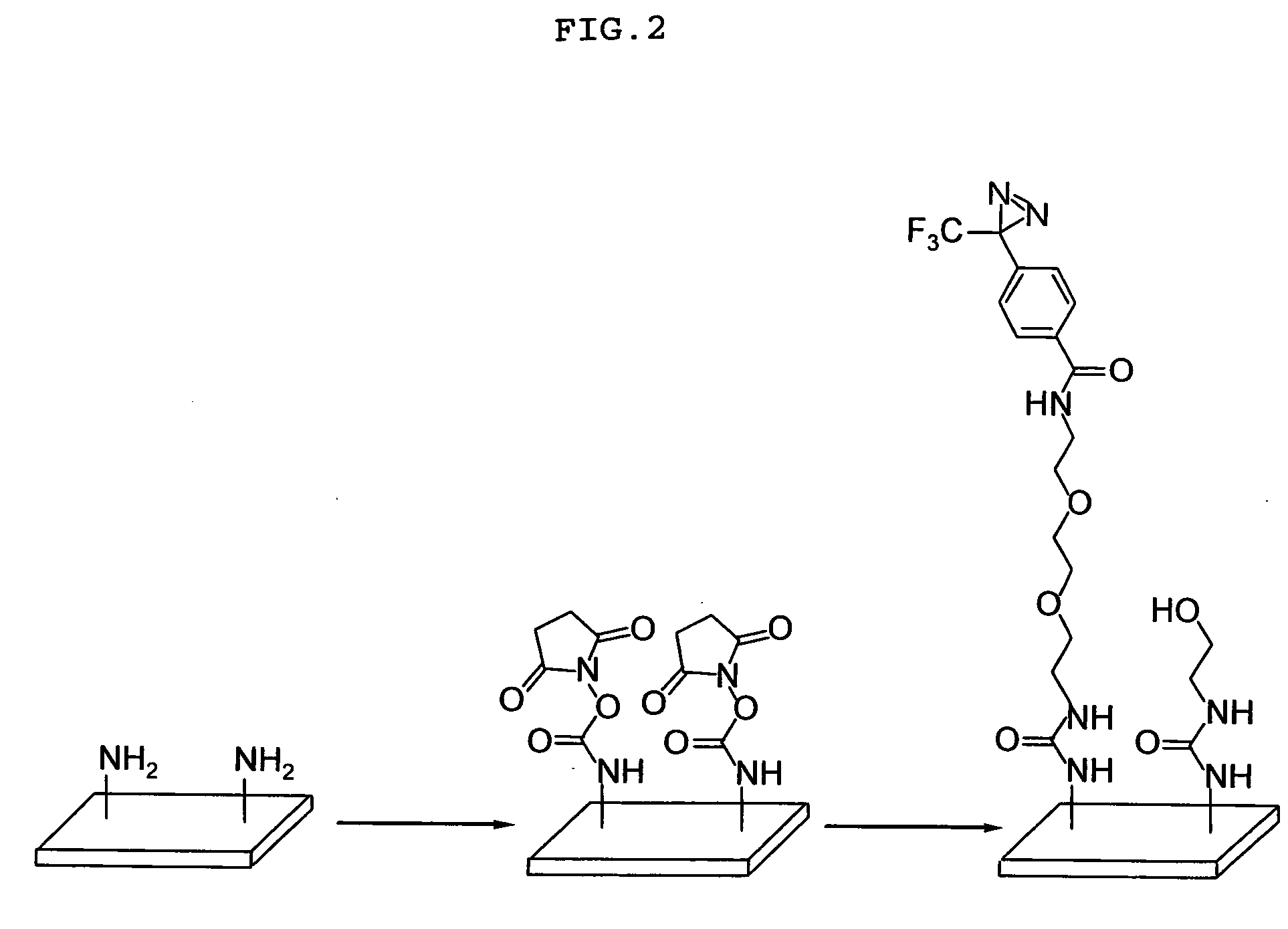

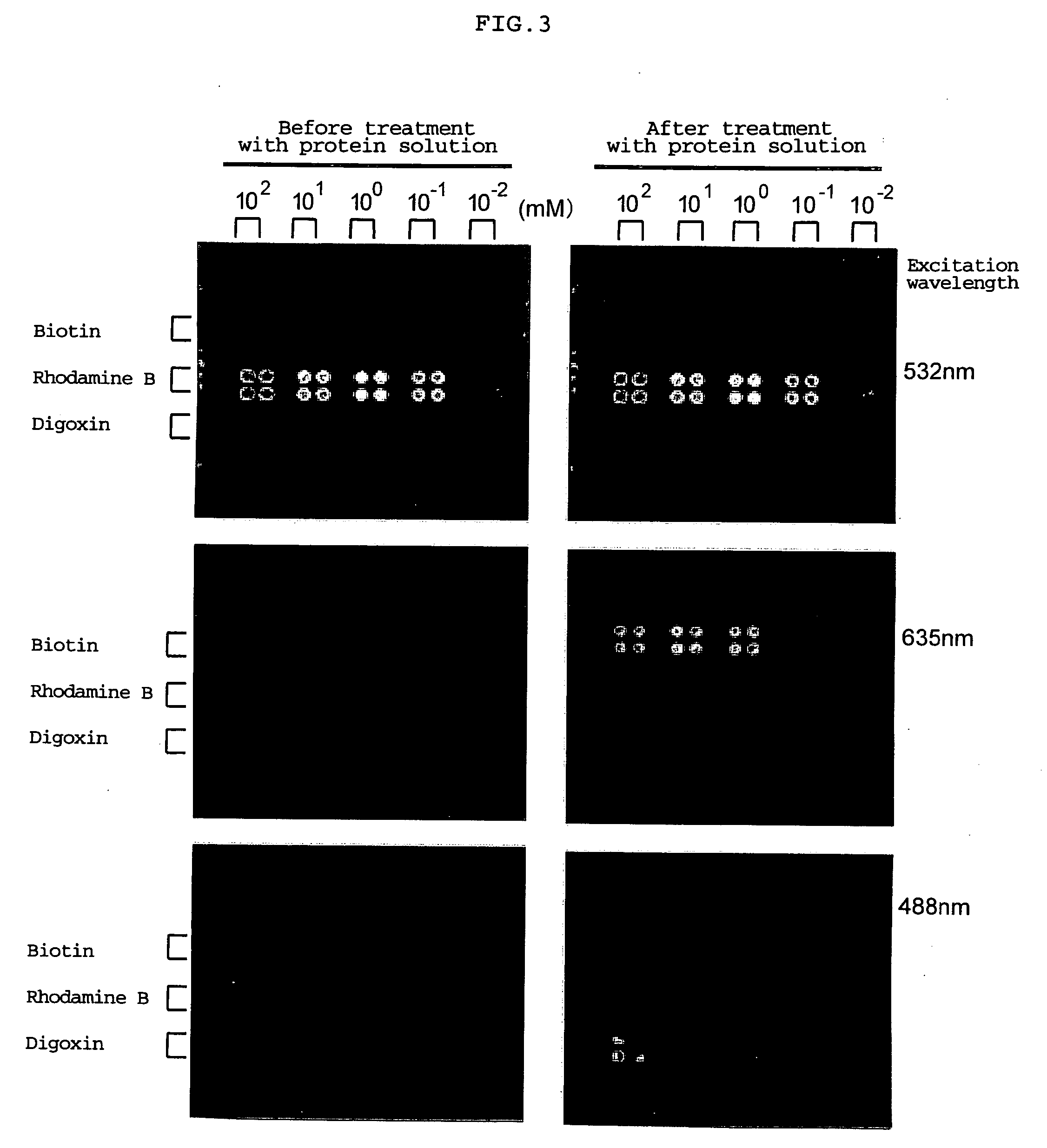

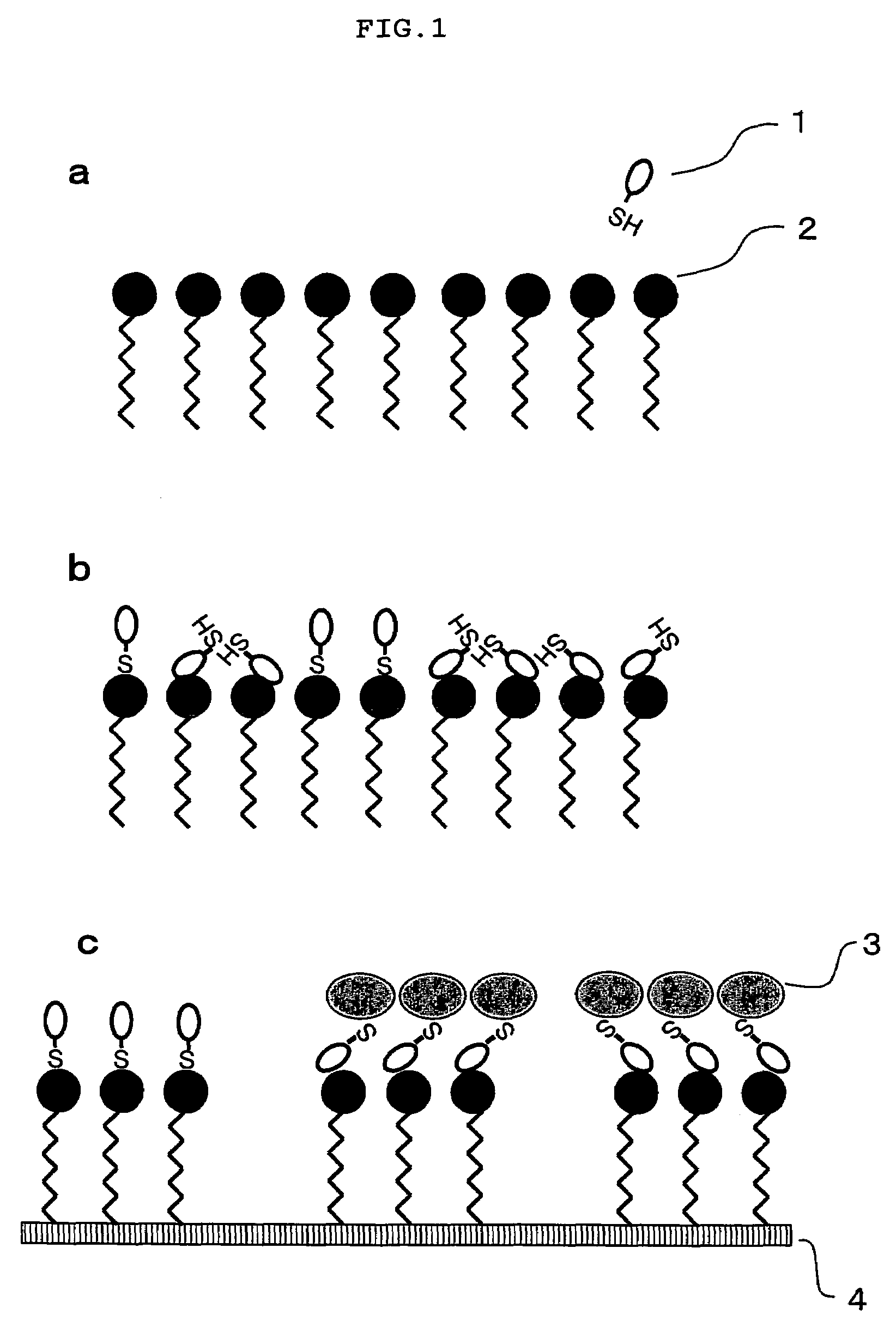

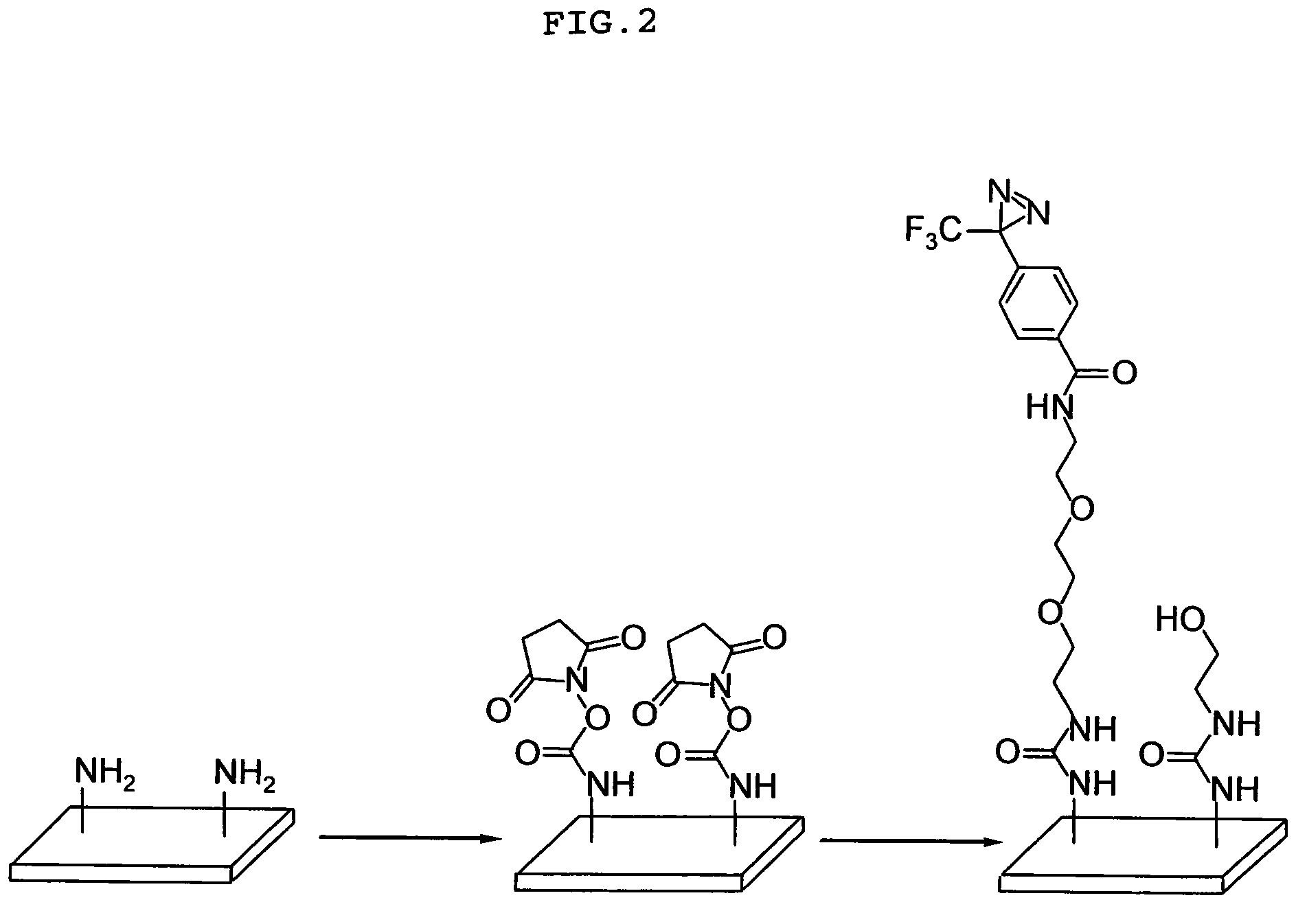

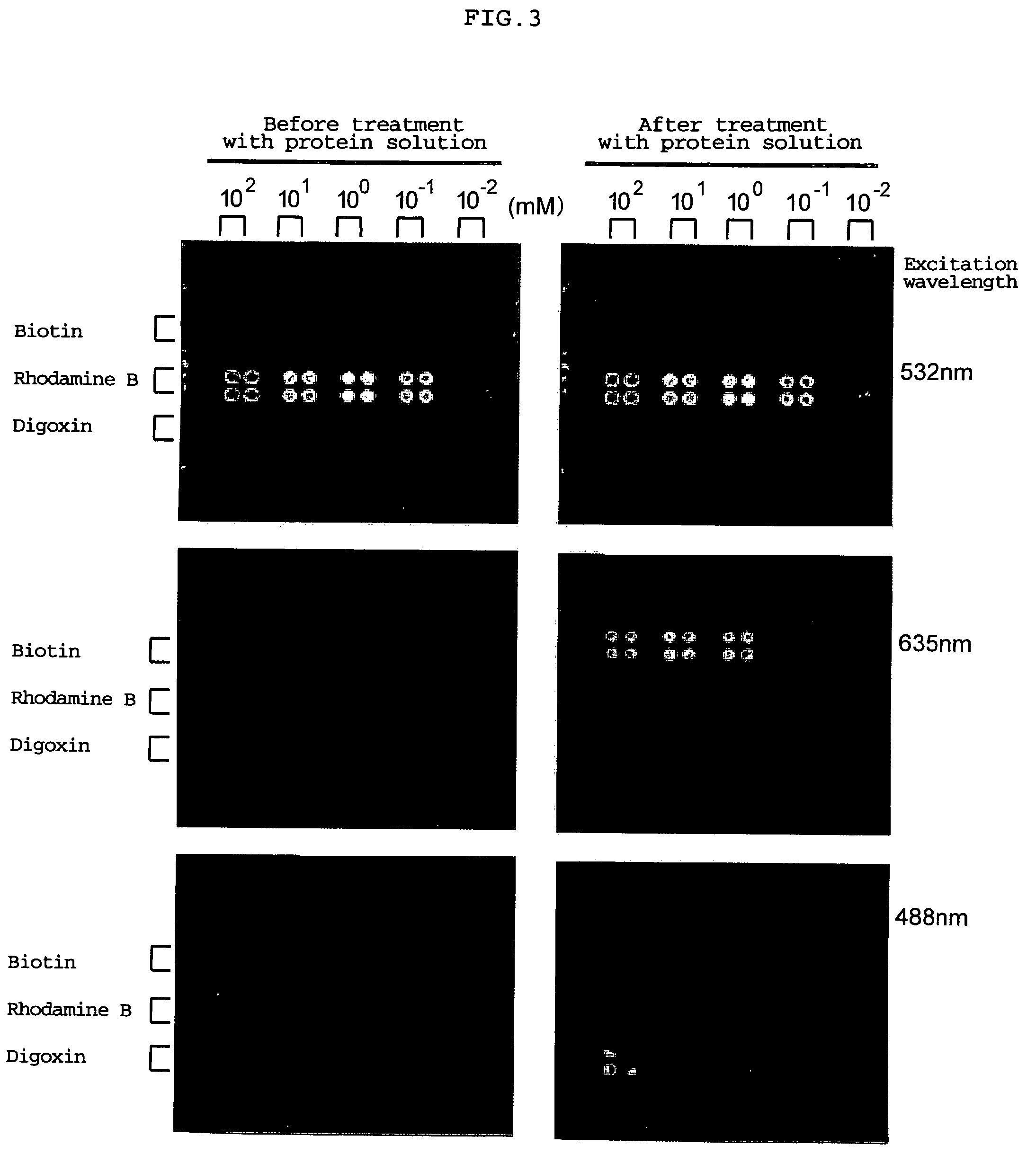

Method of fixing low-molecular compound to solid-phase support

InactiveUS20060194251A1Increase molecular densityImprove reaction efficiencyMaterial nanotechnologyMicrobiological testing/measurementChemical compoundAnalytical chemistry

A method of fixing a low-molecular compound to a solid-phase support, which comprises a step in which a solution containing a low-molecular compound is brought into contact with a solid-phase support having a photoreactive compound bonded to the surface, a step in which the solution containing a low-molecular compound is evaporated to dryness in the state of being in contact with the solid-phase support, and a step in which the solid-phase support is irradiated with light to form a covalent bond between the photoreactive compound and the low-molecular compound. This fixing method enables a low-molecular compound to be fixed to a solid-phase support without the aid of a functional group.

Owner:RIKEN

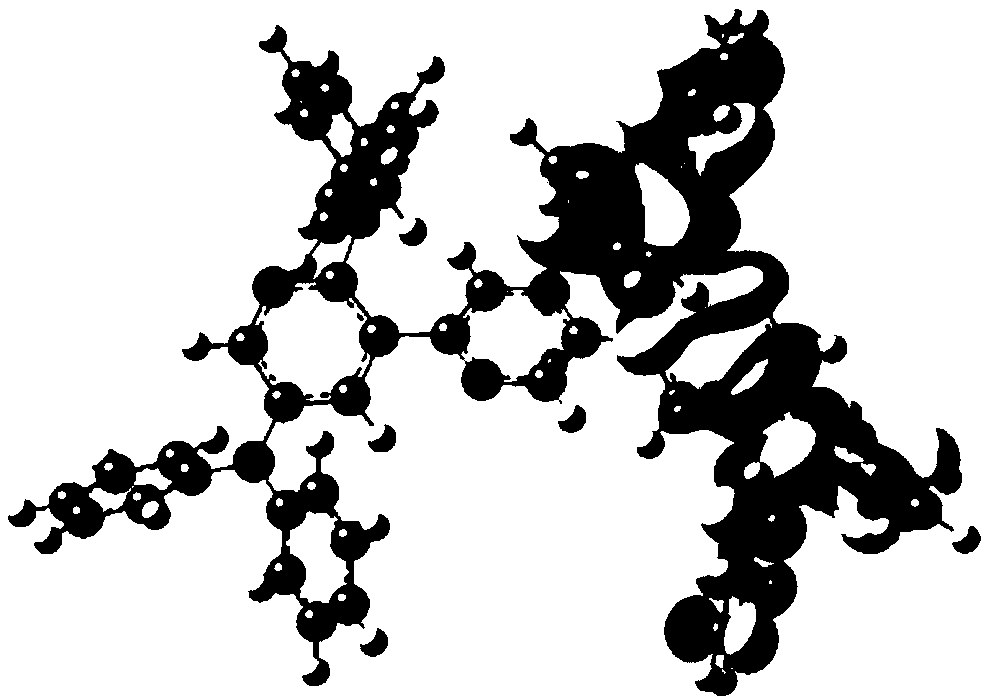

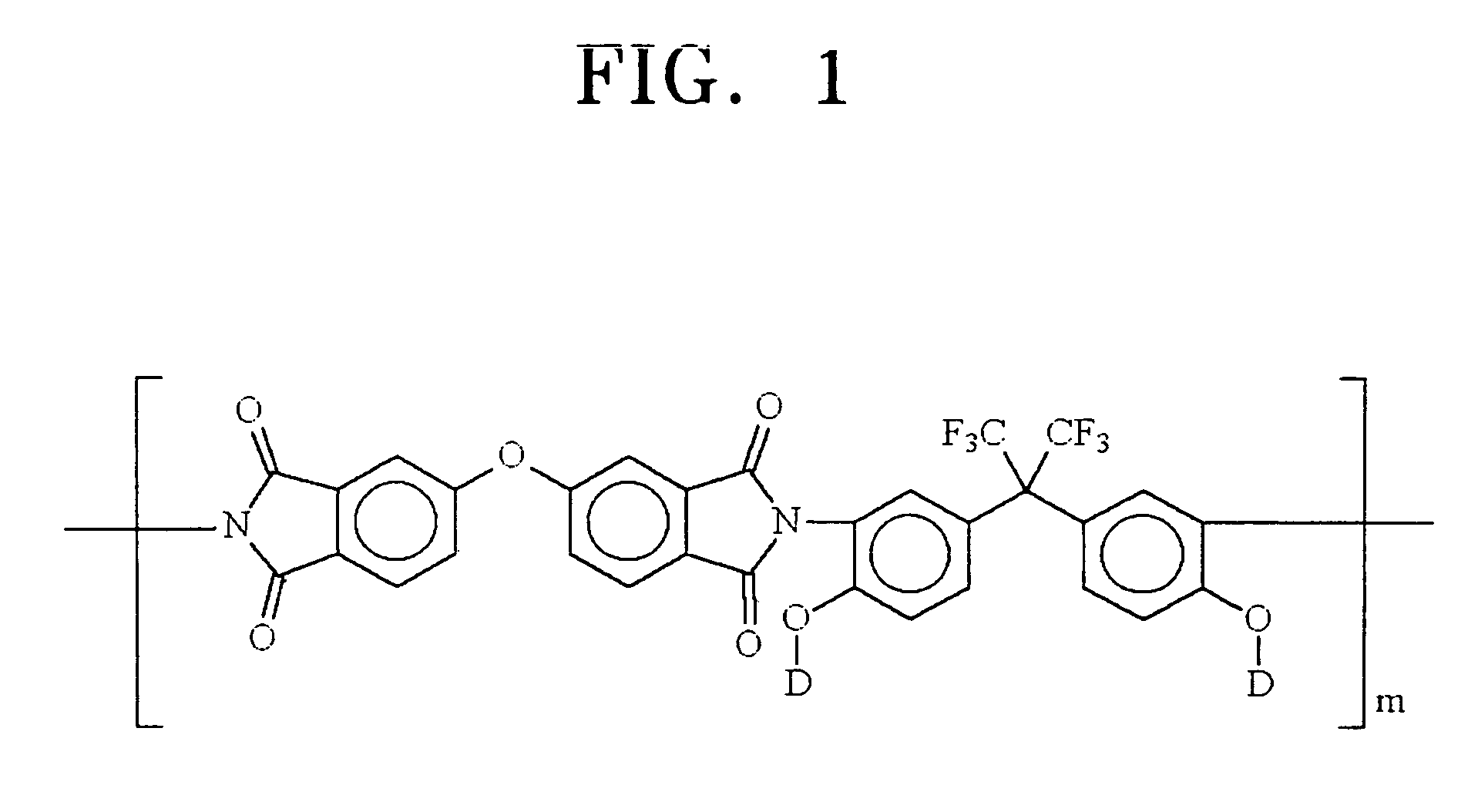

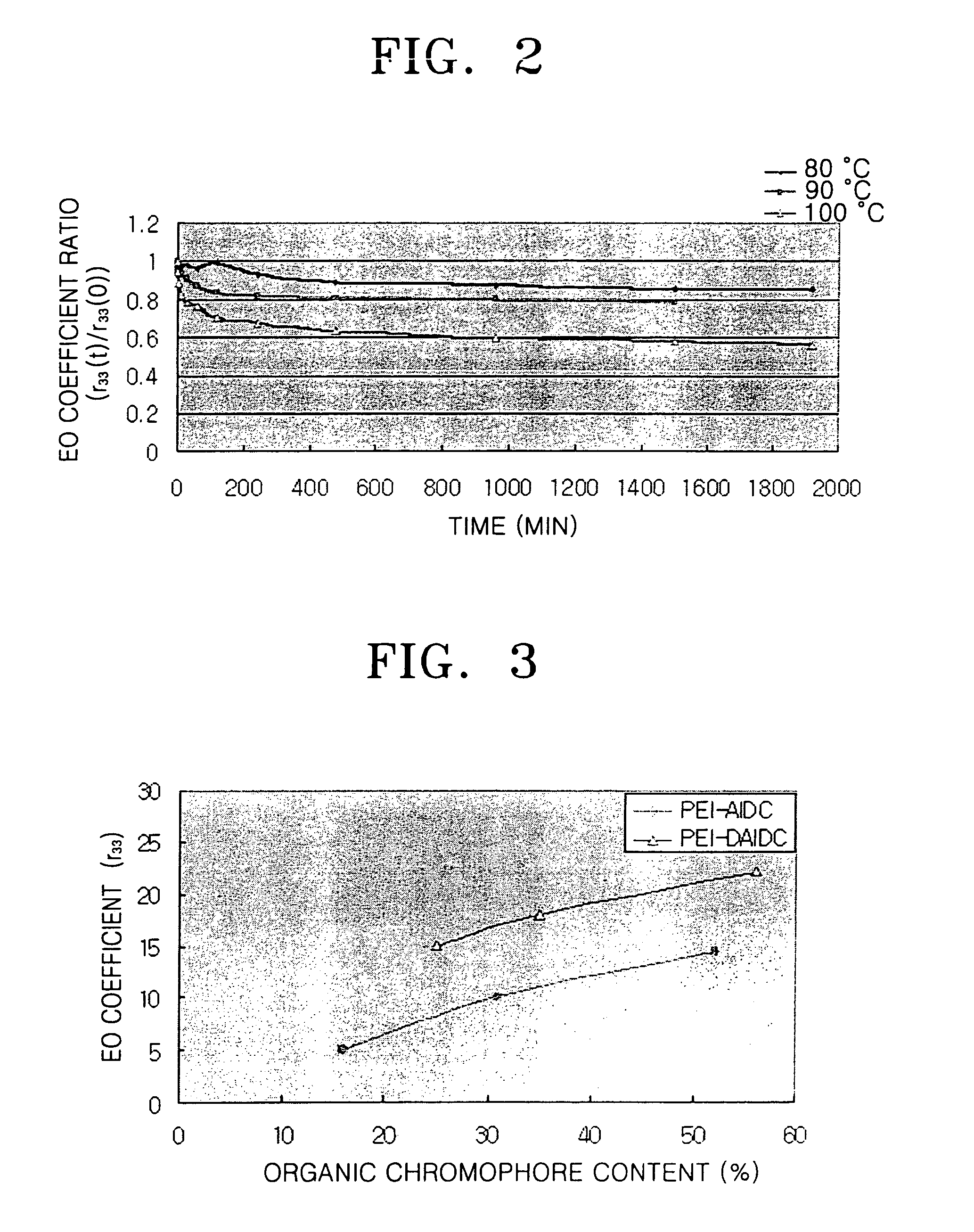

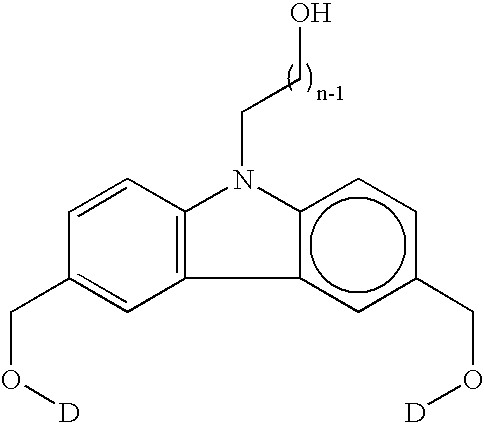

Organic dye molecules and nonlinear optical polymeric compounds containing chromophores

InactiveUS7276188B2Increase molecular densityAdd nonlinearityOrganic chemistryPhotosensitive materialsOrganic dyeBackbone chain

Organic dye molecular materials prepared by coupling existing organic chromophore molecules to benzene or carbazole derivatives and nonlinear optical polymeric compounds having polyimide repeating units coupled with the organic dye molecular material are provided. The organic dye molecular material coupled to a polymer main chain in the preparation of the nonlinear optical polymeric compound has the following formula:where X1 is carbon, oxygen, sulfur, nitrogen, ester (CO2), or amide (CONR1), where R1 is an alky or phenyl group having 1 to 6 carbon atoms, D is an organic chromophore molecule, and n is an integer from 1 to 10.

Owner:ELECTRONICS & TELECOMM RES INST

Method of manufacturing magnetic recording medium, magnetic recording medium and surface treatment apparatus

InactiveUS20090097165A1Improve surface characteristicDecrease in activityLamination ancillary operationsElectric discharge tubesSurface finishingMagnetic layer

The present invention provides a magnetic recording medium having superior startup operation and durability as well as satisfactory surface lubricity. The present invention relates to a method of manufacturing a magnetic recording medium in which at least a magnetic layer, a protective film layer and a lubricant layer are sequentially laminated on a non-magnetic substrate, wherein the lubricant layer is surface treated using a gas activated by plasma generated at a pressure in the vicinity of atmospheric pressure. The present invention also relates to a magnetic recording medium produced according to the aforementioned manufacturing method.

Owner:SHOWA DENKO KK

Organic compound, organic electroluminescent material and application thereof

ActiveCN111808125AIncrease molecular densityMacromolecule densitySolid-state devicesSemiconductor/solid-state device manufacturingOrganic compoundGlass transition

The invention provides an organic compound, an organic electroluminescent material and application thereof. The organic compound has a structure as shown in a formula I. Through the special design ofa mother nucleus structure and a substituent group, the organic compound has a high triplet state energy level ET, a large molecular density, a high glass transition temperature and high molecular thermal stability, effectively improves carrier balance migration, broadens an exciton recombination region, improves the light extraction efficiency and substantially improves the luminescence efficiency and service life of an electroluminescent device. The organic compound can be used in a light-emitting layer or an electron transport layer of an OLED device, is especially suitable for being applied to the light-emitting layer of the OLED device as a phosphorescent host material, can significantly improve the light-emitting efficiency and chromaticity of the device, reduces the turn-on voltageand energy consumption of the device, and prolongs the service life of the device.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD

Magnetocompression-assisted fusion

InactiveUS20180268945A1Improve approachLess separationNuclear energy generationConductive materialBinding energyHydrogen atom

A method for facilitating fusion by magnetocompression of hydrogen isotopes. A magnetic field of at least 105 T is exposed to fuel including hydrogen isotopes. After exposure to the magnetic field, the fuel is energized by a laser, ionizing the hydrogen and converting the fuel to plasma. The magnetic field compresses internuclear separation of H2+. The magnetic field also compresses the electron radius of hydrogen atoms, resulting in increased electron binding energy. Each of these changes accompanying magnetocompression facilitates fusion of the nuclei following laser excitation. A solenoid for enhancing magnetic fields is also described. The solenoid includes conduction member defining a cavity therein. The conduction member is a highly conductive material, which may include a composite of a semiconductor and a conductor. The solenoid may be applied to hold the fuel or in any application to concentrate the magnetic field in a small volume.

Owner:1994680 ALBERTA LTD

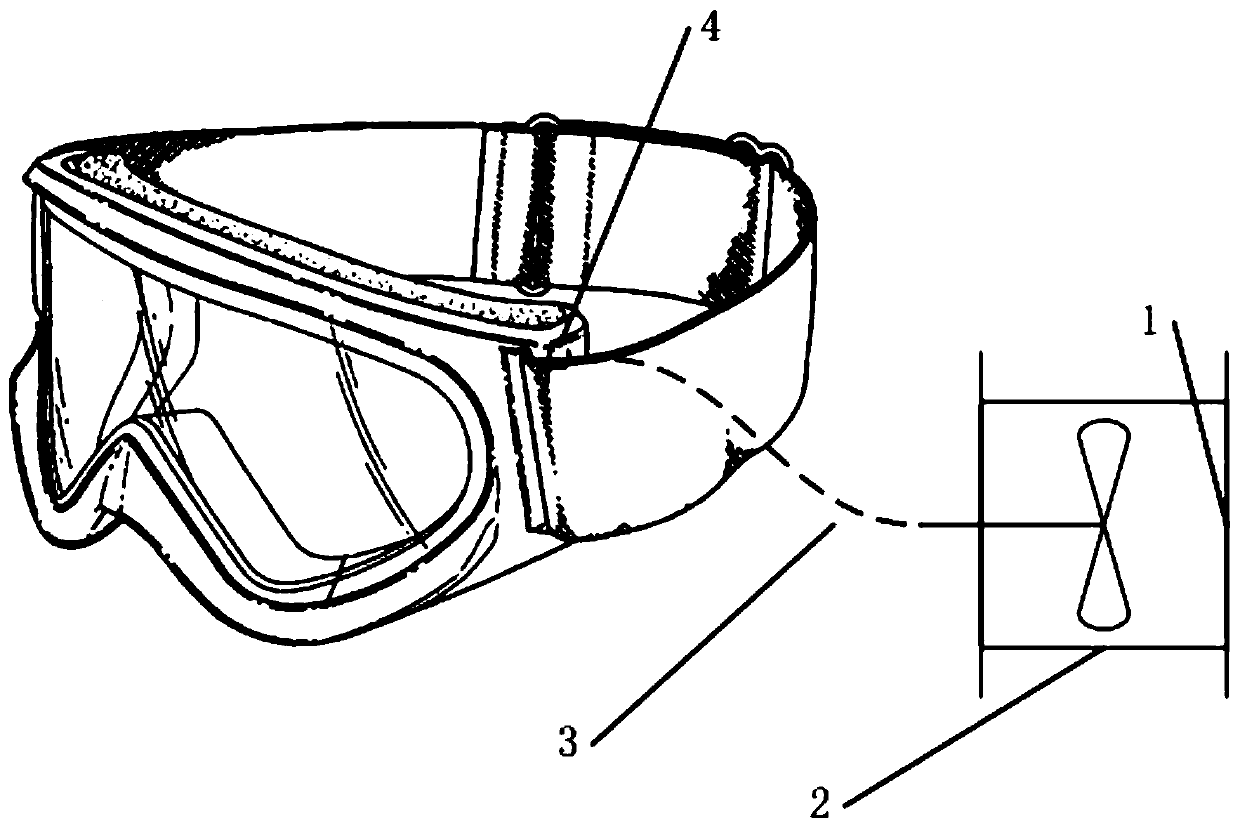

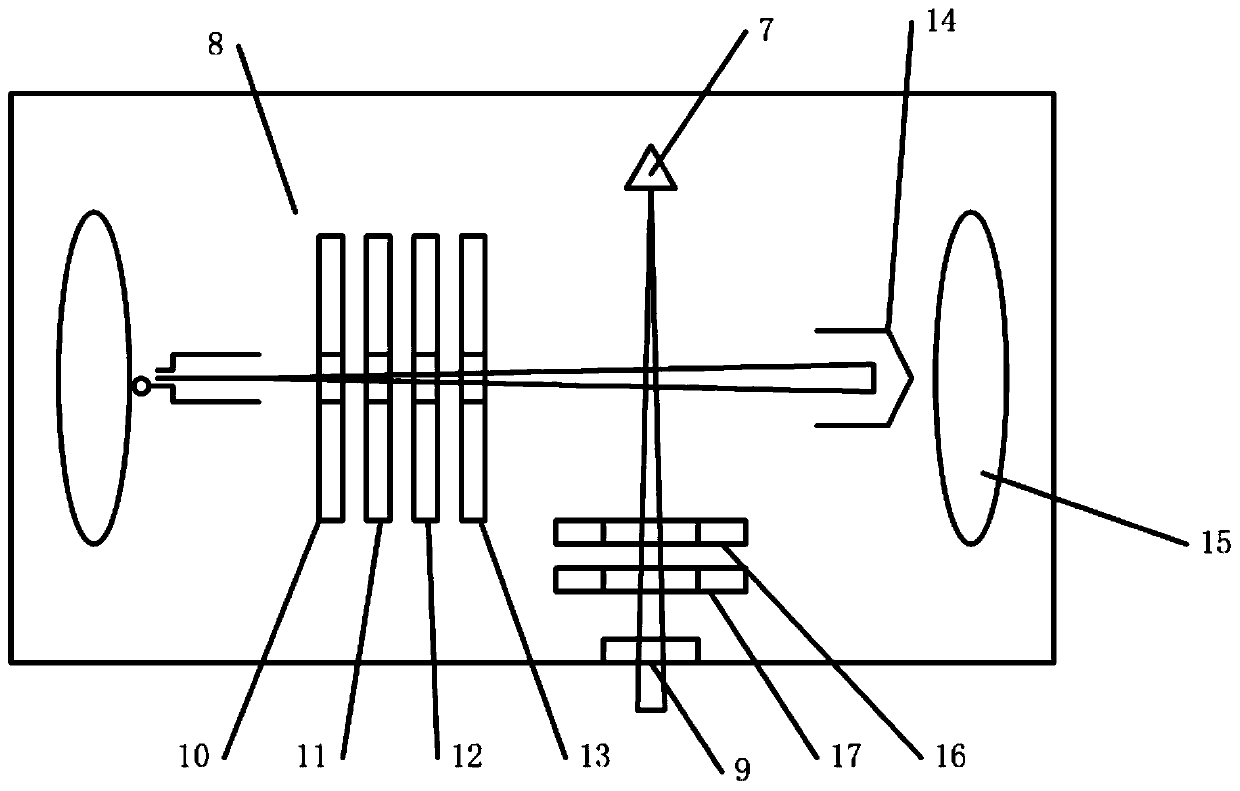

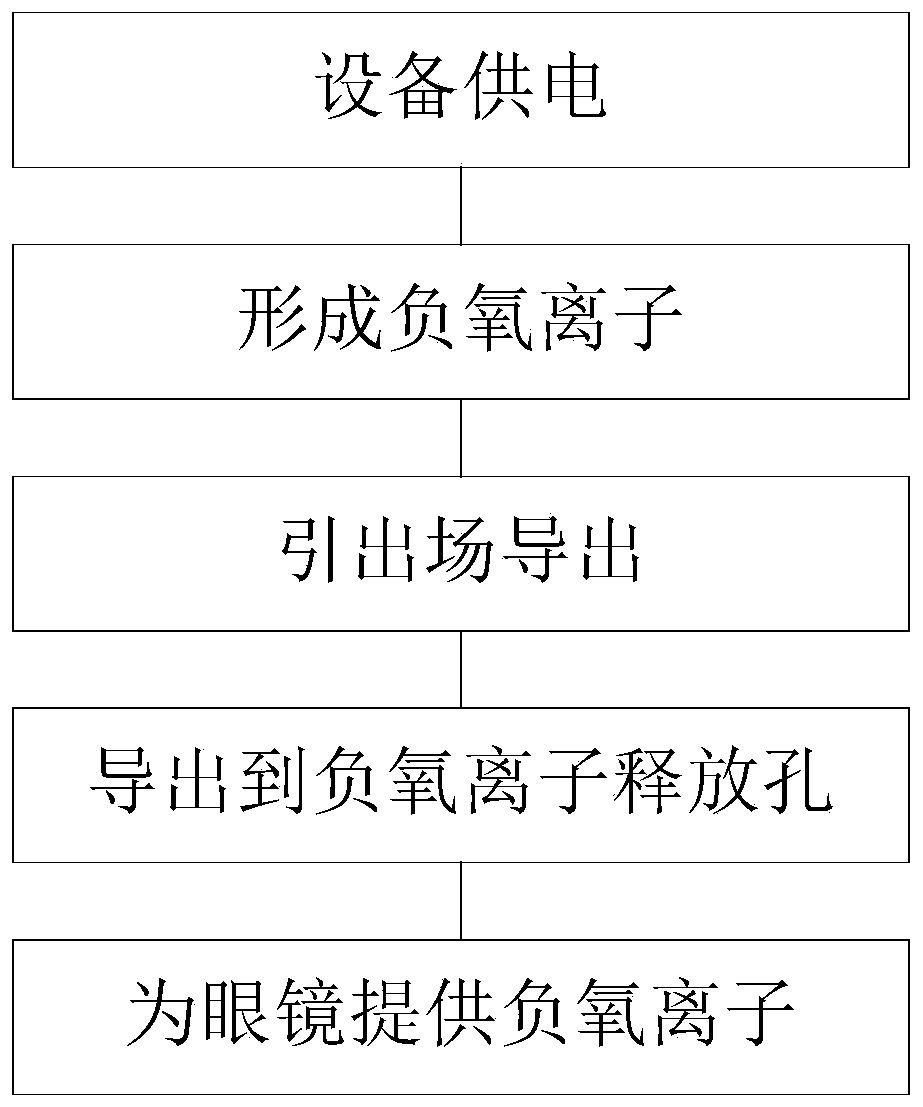

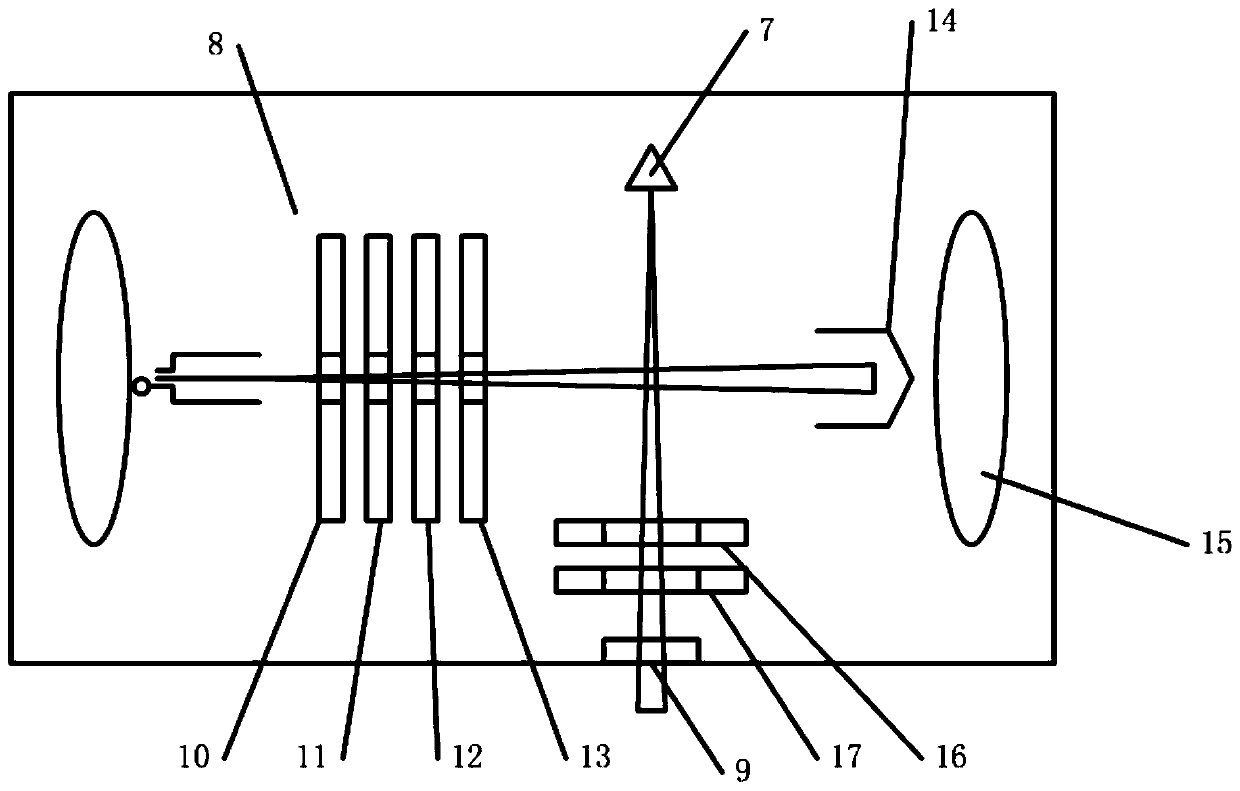

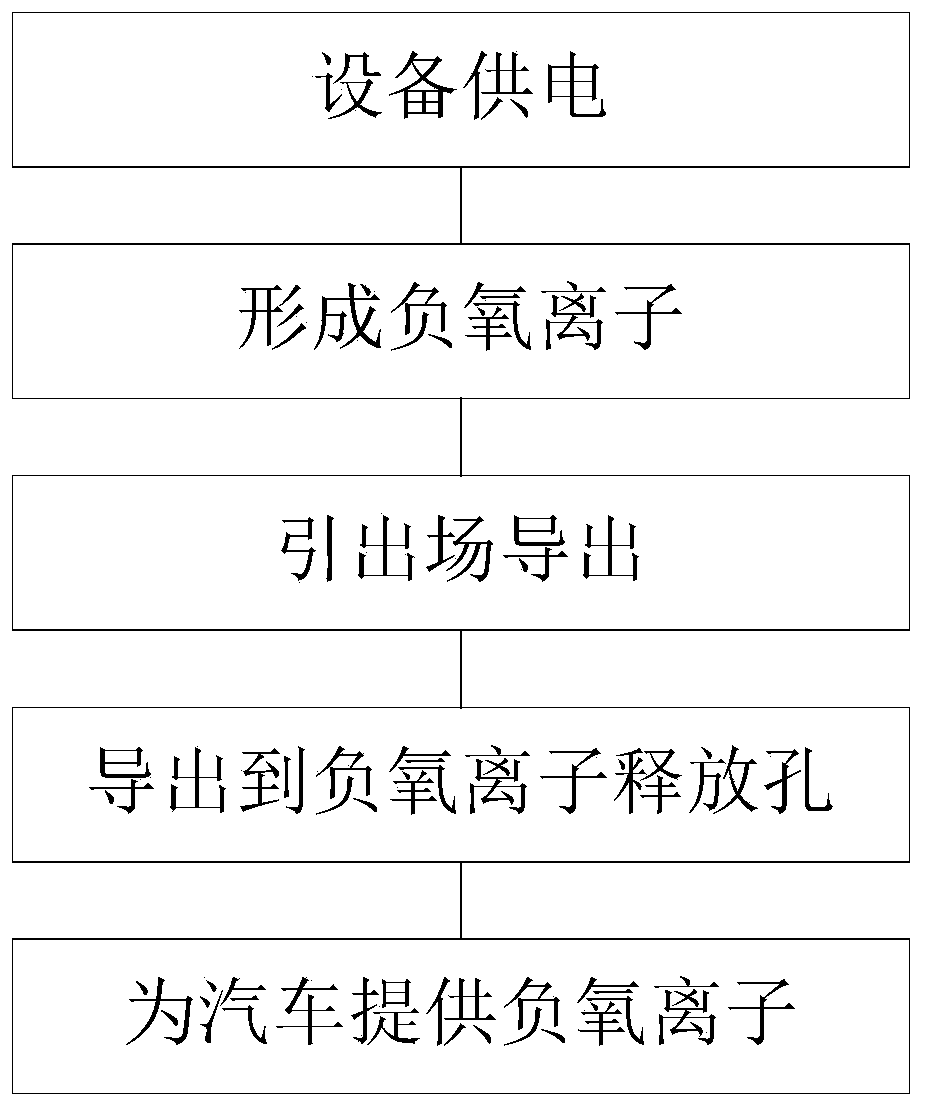

Design preparation method of miniaturized negative ion goggles and negative ion goggles

The invention belongs to the technical fields of air purification and human health, and particularly relates to a design preparation method of a pair of miniaturized negative ion goggles and the negative ion goggles. Specifically, the method comprises the following steps: (1) supplying power to various devices in a small negative oxygen ion generator 2 by using a battery or a mobile power source 1; (2) compressing the air by an air beam source 7 in the small negative oxygen ion generator to generate an air beam and vertically illuminating to an electric field generated by a negative ion generating electrode 8 to form negative oxygen ions; and (3) flying the negative oxygen ions into an extraction field under the inertia of the air beam, and leading out to an air supply hole of the small negative oxygen ion generator by the extraction field. The structure and method of the present invention are used for rehabilitation patients and users of eye diseases, and the small negative oxygen iongenerator of the present structure is connected to the glasses through a negative oxygen ion transport tube, the small negative oxygen ion generator can be fixed to other parts of the body without the need to be fixedly connected to the glasses, and the structure is more portable.

Owner:SUZHOU UNIV OF SCI & TECH

Compound, light extraction material and organic electroluminescent device

ActiveCN112939959AGood planaritySpeed up removalIsotope introduction to heterocyclic compoundsSolid-state devicesDisplay deviceOrganic electroluminescence

The present application provides a compound of general formula (I), and the compound can be used in light extraction materials. Pyridine and connected aromatic groups in the parent nucleus structure of the compound have good planarity, and the compound can be used as a light extraction material to improve the luminous efficiency of an organic electroluminescent device. The invention further provides an organic electroluminescent device and a display device.

Owner:YANTAI XIANHUA CHEM TECH CO LTD +1

Method of fixing low-molecular compound to solid-phase support

InactiveUS7713706B2Increase molecular densityImprove reaction efficiencyMaterial nanotechnologyMicrobiological testing/measurementAnalytical chemistrySolid phases

A method of fixing a low-molecular compound to a solid-phase support, by bringing a solution containing a low-molecular compound into contact with a solid-phase support having a photoreactive compound bonded to the surface, evaporating the solution containing a low-molecular compound to dryness, in the state of being in contact with the solid-phase support, and irradiating the solid-phase support with light to form a covalent bond between the photoreactive compound and the low-molecular compound. This fixing method enables a low-molecular compound to be fixed to a solid-phase support without the aid of a functional group.

Owner:RIKEN

Interior decoration coating for automobile lamp with good adhesion force

The invention relates to an interior decoration coating for an automobile lamp. The coating comprises the following components by weight: 25 to 35% of novolac epoxy resin, 20 to 30% of acrylic resin, 5 to 10% of polyester resin, 3 to 5% of TM resin, 2 to 7% of TP resin, 2 to 3% of an initiator, 3 to 4% of an auxiliary agent and 30 to 40% of a solvent, wherein the solvent is prepared from mixing propyl butyl ester and ethyl ester with a weight proportion of 10 to 20% of propyl butyl ester and 80 to 90% of ethyl ester; the initiator is one or two selected from the group consisting of benzophenone and alpha-hydroxy ketone; and the auxiliary agent is one or more selected from the group consisting of a drying promoter, a toughening agent, a defoaming agent, a leveling agent, a light stabilizer, etc.. The interior decoration coating for the automobile lamp is effectively regulated in an internal chemical structure and a molecular structure of the coating; and the molecular content of the coating is in a range of 15000 to 30000, so depainting, dark-moire and yellowing phenomenons of a modified resin coating in the prior art are changed.

Owner:江苏飞翔涂料有限公司

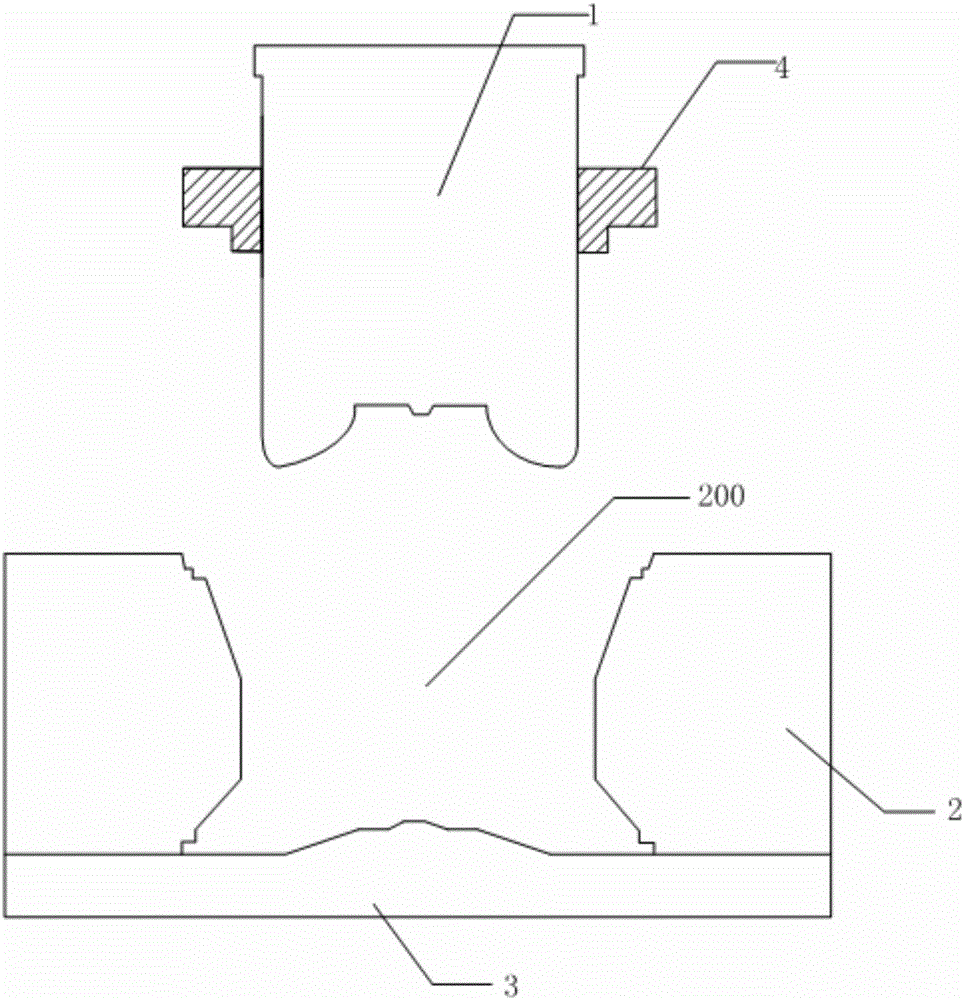

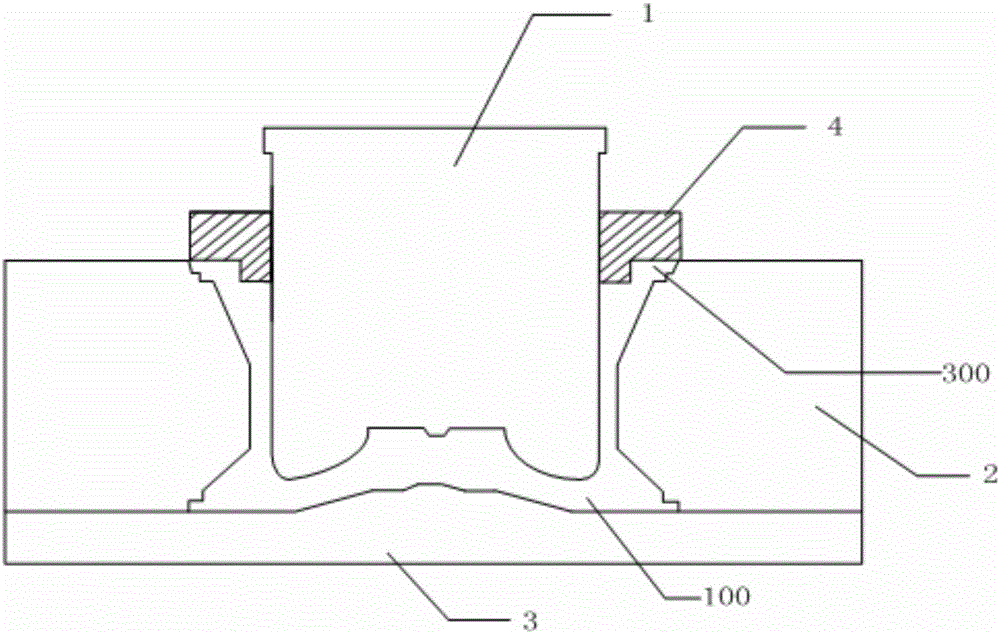

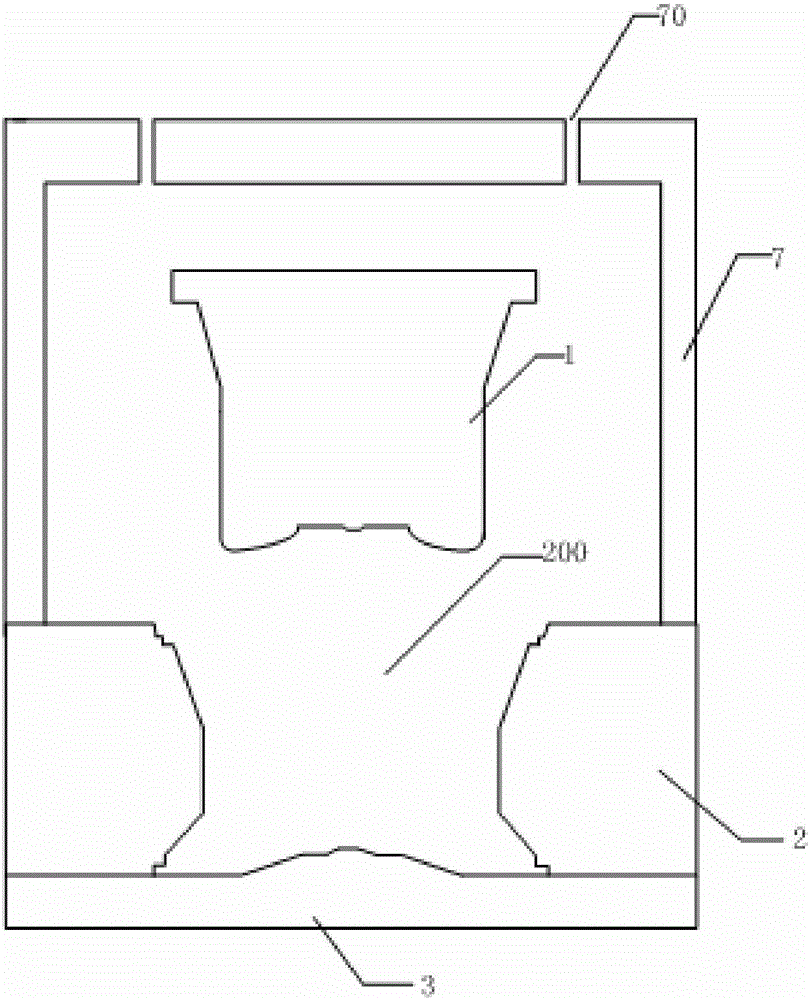

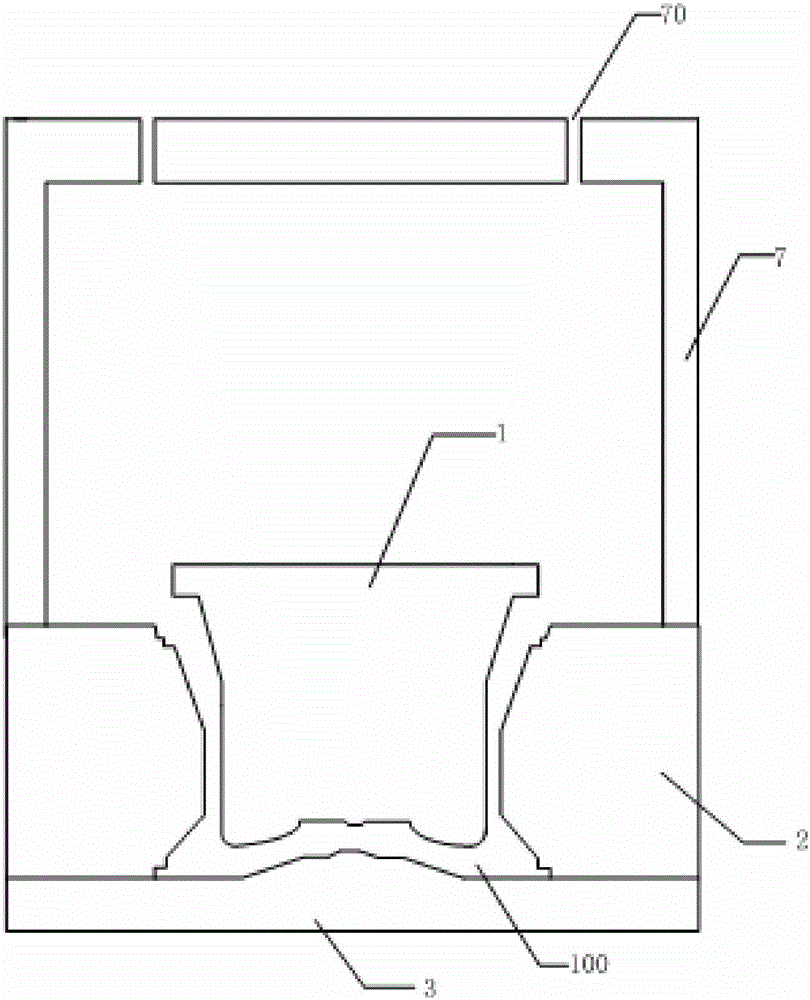

Hub manufacturing equipment and hub manufacturing method

InactiveCN106583483ASimple manufacturing processImprove yieldShaping toolsExtrusion diesFiberCarbon fibers

The embodiment of the invention discloses hub manufacturing equipment and a hub manufacturing method. In order to manufacture a hub through an extrusion forging process and effectively improve the hub performance, the hub manufacturing equipment and the hub manufacturing method are invented. The hub manufacturing equipment comprises a first male die, a flanging die, a side die and a second male die; the first male die and the second male die are oppositely arranged, the flanging die is arranged on the periphery of the first male die in a sleeving manner, and the side die is arranged between the first male die and the second male die; the first male die and the flanging die can move relative to the second male die; when the side die, the first male die and the second male die are matched, a die cavity of the hub is formed along the side die, the first male die and the second male die; when the flanging die, the side die and the second male die are matched, a flanging die cavity of the hub is formed between the inner side of the top of the side die and the flanging die; and the flanging die and the first male die simultaneously or asynchronously move relative to the second male die. The embodiment can be applied to hub manufacturing through materials such as an aluminum alloy, a magnesium alloy, carbon fibers and a composite material.

Owner:郝鑫颖

Compound, organic photoelectric device and electronic equipment

ActiveCN110194720AFast radiative transition rateHigh triplet energy levelOrganic chemistrySolid-state devicesHigh electronThermal stability

The present invention relates to a compound, an organic photoelectric device and electronic equipment, wherein the compound has a structure represented by a formula (I), a formula (II), a formula (III), a formula (IV), a formula (V) or a formula (VI), the organic photoelectric device comprises an anode, a cathode, and at least an organic thin film layer positioned between the anode and the cathode, the organic thin film layer comprises any one of the compounds or a combination comprising at least two selected from the compounds, and the electronic equipment comprises the organic photoelectricdevice. According to the present invention, the compound has characteristics of high hole, high electron mobility and high thermal stability, and can achieve high light emitting efficiency, low driving voltage and long service in organic photoelectric devices.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD

A kind of antistatic automobile polishing wax integrating cleaning and glazing and preparation method thereof

ActiveCN106085247BHas the function of absorbing ultraviolet raysIncrease brightness functionInorganic/elemental detergent compounding agentsCationic surface-active compoundsPolystyreneSolvent

Owner:DONGGUAN UNIV OF TECH

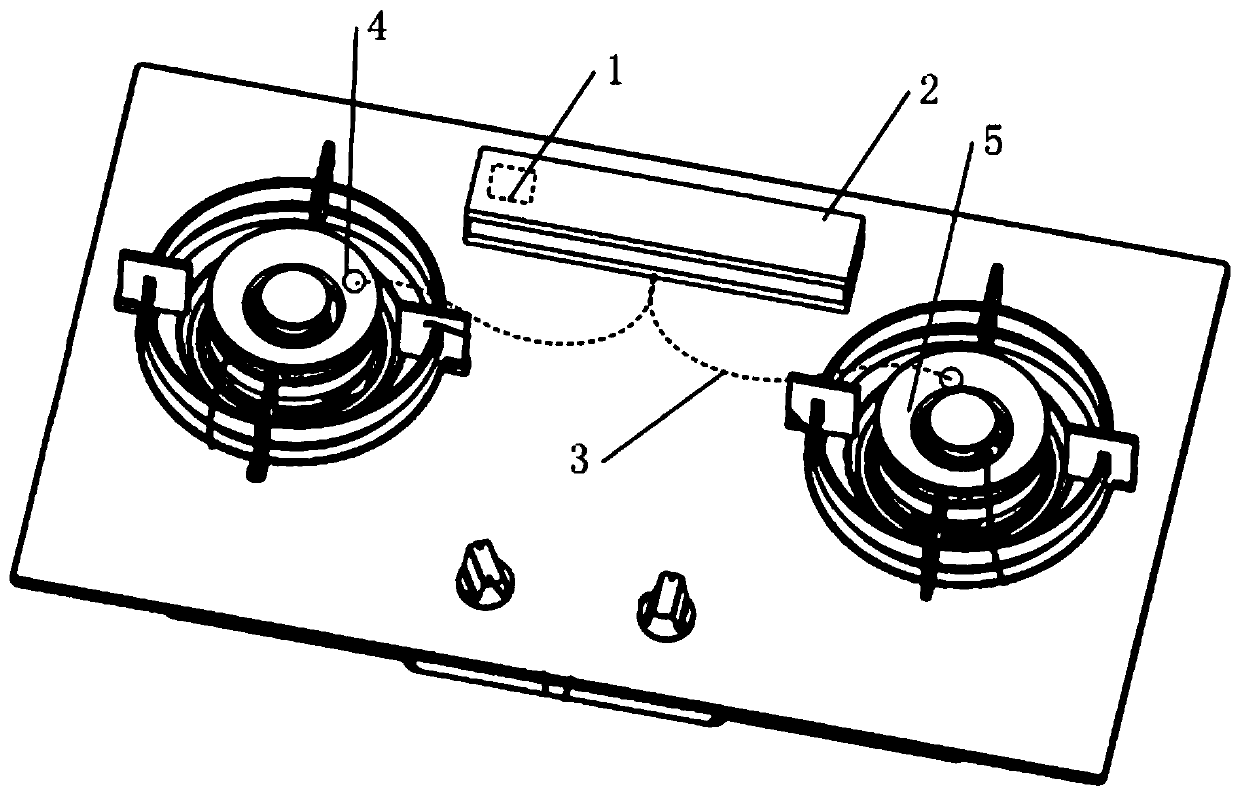

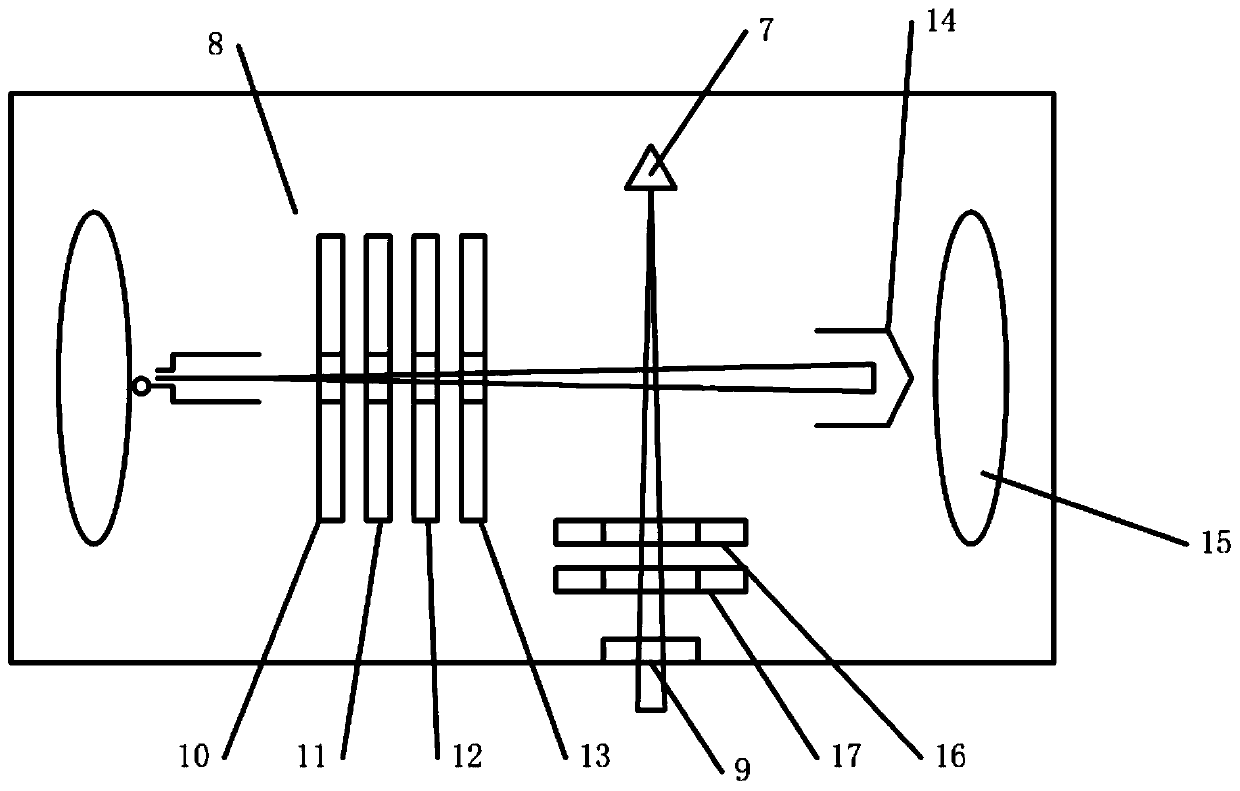

Negative oxygen ion energy-saving gas stove and design and preparation method thereof

InactiveCN110207150AImprove combustion efficiencyIncrease incidenceDomestic stoves or rangesElectrical apparatusOxygen ionsOxygen content

The invention belongs to the field of gas stoves, and particularly relates to a negative oxygen ion energy-saving gas stove and a design and preparation method thereof. The gas stove comprises a gas stove panel and a gas stove bottom box, and further comprises a substrate, a negative oxygen ion release hole, a negative oxygen ion delivery pipe, a small negative oxygen ion generator, and a storagebattery or a mobile power supply; the substrate is located beside fuel gas nozzles; the negative oxygen ion release hole is located in the center of the substrate; one end of the negative oxygen ion delivery pipe is connected with the negative oxygen ion release hole; the other end of the negative oxygen ion delivery pipe is connected with the small negative oxygen ion generator; and the small negative oxygen ion generator is provided with the storage battery or the mobile power supply. Negative oxygen ions generated by the method are mixed with fuel gas, the negative oxygen ions can effectively purify impurities in the fuel gas, meanwhile, the oxygen content during combustion of the fuel gas is increased, and the combustion efficiency of the fuel gas is improved.

Owner:宿迁龙相高新技术服务有限公司

Paint for vacuum coating of car lights

InactiveCN105199568AImprove adhesionLow costEpoxy resin coatingsPolyester coatingsPolyesterAcrylic resin

The invention relates to paint for vacuum coating of car lights. The paint comprises the following ingredients in percentage by weight: 40-50% of polyester acrylic resin, 10-15% of a TM acrylic monomer, 18-25% of a TP acrylic monomer, 5-10% of phenolic aldehyde epoxy resin, 6-11% of a photoinitiator, 0.5-1.5% of one or additives, 5-10% of ethyl ester and the balance of a solvent, wherein the solvent is a mixture of butyl propionate and ethyl ester; the ratio of butyl propionate to ethyl ester is 1:2.4; the photoinitiator is an ultraviolet light absorbent; the additives comprise one or more of a drying agent, a toughening agent, an antifoaming agent, a leveling agent, a photostabilizer, an accelerating agent, a dispersing agent and the like. Compared with like vacuum paint, the paint provided by the invention has the advantages that the cost is reduced by about 40%, convenience is brought for construction, and the one-time qualification rate is high.

Owner:江苏飞翔涂料有限公司

Weather-resistant natural composite material integrated wall panel and preparation method thereof

The invention relates to a weather-resistant natural composite material integrated wall panel and a preparation method thereof. The weather-resistant natural composite material integrated wall panel is characterized by comprising the following raw materials and components in parts by weight: 50 parts of light calcium carbonate, 50 parts of a recycled autogenous grinding material, 25 parts of SG-8polyvinyl chloride resin, 8 parts of log bamboo powder, 25 parts of PVC tube material, 2.5 parts of CS-108 tubular product PVC efficient rear earth compound stabilizer, 0.4 part of a yellow foaming agent, 0.3 part of a white foaming agent, 3.9 parts of ZB-760 PVC foaming conditioning agent, 0.05 part of PE WAX PE wax and 0.32 part of 1840 type stearic acid. The wall panel is mold-proof and waterproof, the elasticity and plasticity of wall are increased, the effect after construction is uniform and attractive in appearance, and the promotion of brightness is extremely obvious. Rejected materials are adopted as the raw materials mostly, the cost is low, secondary utilization of the rejected materials is reached, the environment is protected, and the economical benefit is remarkable.

Owner:宣恩九发科技有限公司

Processing technology of high-quality sweet potato noodles

The invention discloses a processing technology of high-quality sweet potato noodles. The processing technology is characterized by comprising the following steps of (1) preparing a starchy sauce; (2) performing dough mixing, making noodles; (3) performing ageing treatment; and (4) performing ageing post-treatment. The sweet potato noodles finally made by the processing technology disclosed by the invention are bright in color, good in mouth feel, high in intensity and high in chewiness, phenomena of adhesion and breaking after the high-quality sweet potato noodles are cooked are not liable to generate, and good economic benefits can be generated.

Owner:肥西县金桥红薯专业合作社

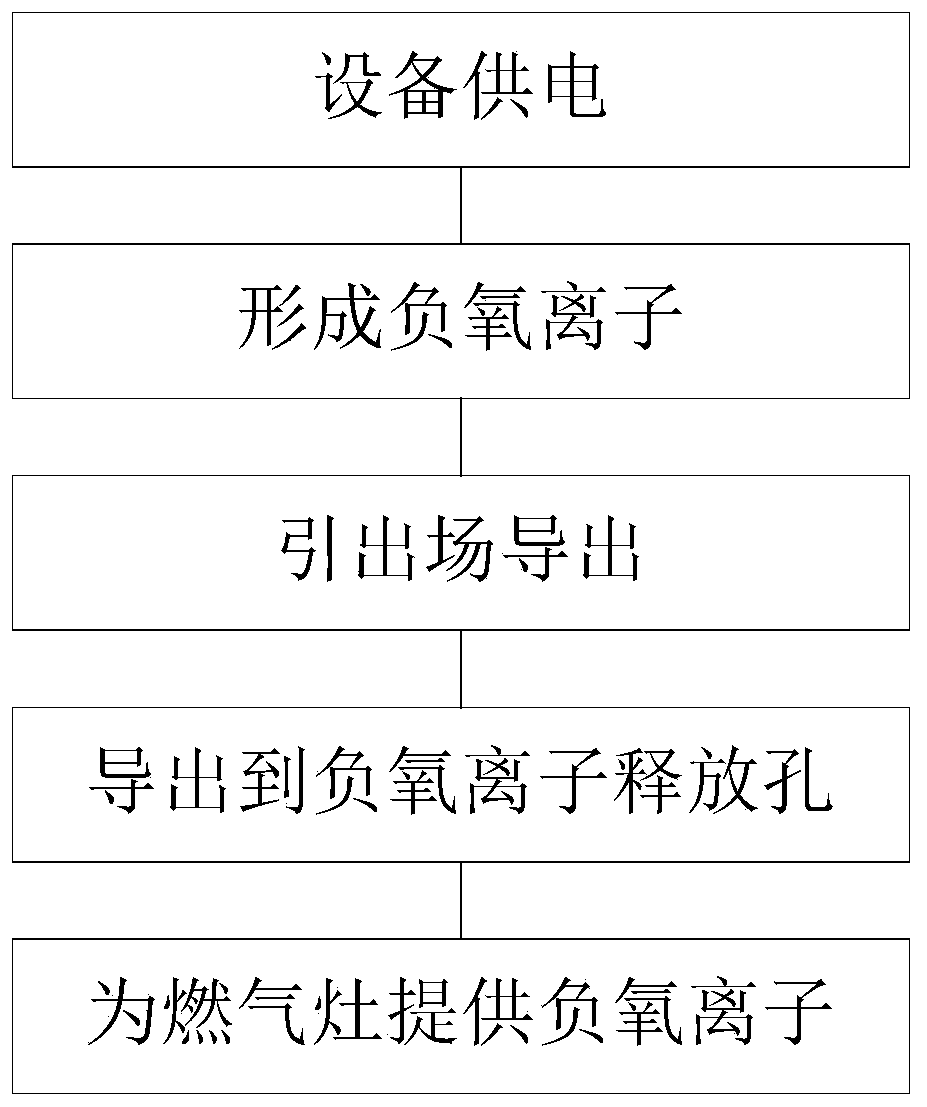

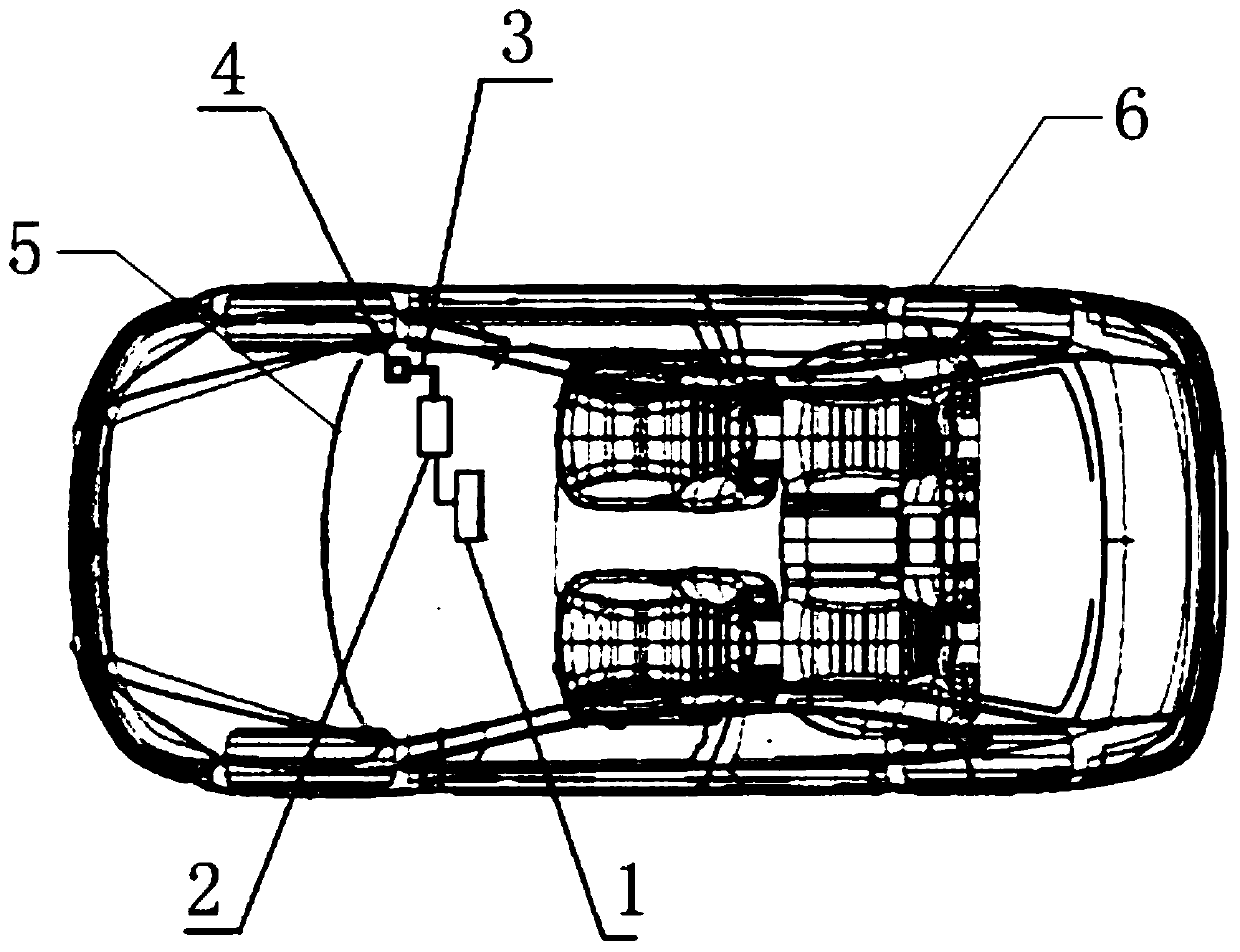

Vehicle-mounted negative ion air supply system and design and operation method thereof

The invention belongs to the technical field of air purification and human health, and particularly relates to a vehicle-mounted negative ion air supply system and design and operation method thereof.The system comprises a vehicle body, a base plate, a negative oxygen ion release hole, negative oxygen ion transport pipe, a small negative oxygen ion generator, an accumulator and a mobile power supply, and is characterized in that the base plate is located on the inner wall of the vehicle body and connected with the inner wall of the vehicle body in a welded mode, the negative oxygen ion release hole is located in the center of the base plate and connected to one end of the negative oxygen ion transport pipe, and the small negative oxygen ion generator is connected to the other end of the negative oxygen ion transport pipe, and the accumulator or the mobile power supply is installed on the small negative oxygen ion generator. According to the system, negative oxygen ions are provided inthe vehicle, the content of the negative oxygen ions in the air is increased, and driver fatigue is advantageously relieved.

Owner:宿迁龙相高新技术服务有限公司

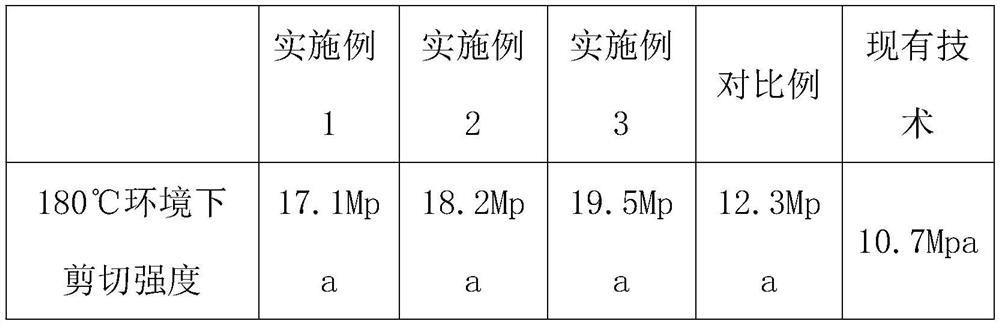

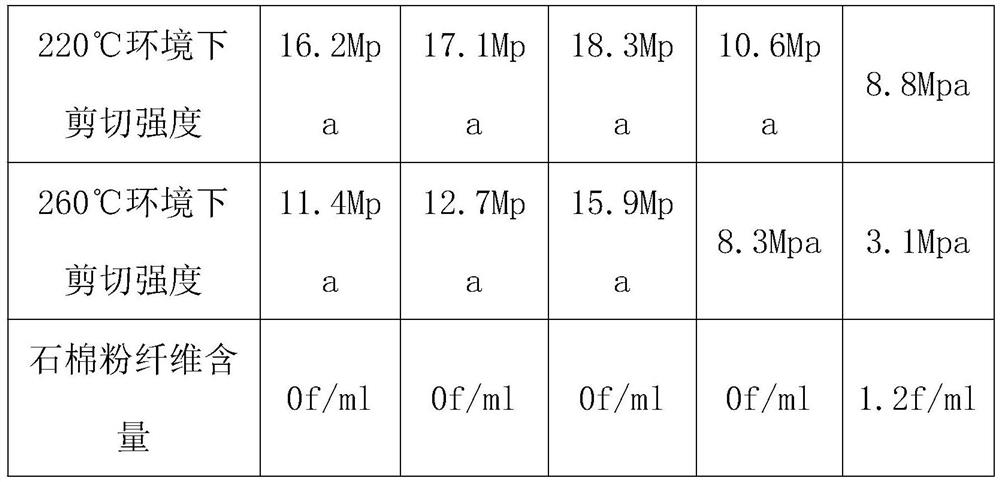

Cooking-resistant modified polyurethane adhesive and preparation method thereof

PendingCN114507500AExcellent retort resistanceImprove toughnessNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesEpoxyDiphenylmethane

The invention discloses a steaming and boiling resistant type modified polyurethane adhesive and a preparation method of the steaming and boiling resistant type modified polyurethane adhesive, and belongs to the technical field of adhesives. The cooking-resistant modified polyurethane adhesive is prepared from the following components in parts by mass: 20 to 25 parts of oxalic acid, 10 to 15 parts of diethylene glycol, 10 to 15 parts of ethylene glycol, 8 to 10 parts of diphenylmethane diisochlorate, 3 to 5 parts of ethyl acetate, 20 to 25 parts of A-type modified epoxy resin, 20 to 25 parts of B-type modified epoxy resin, 4 to 6 parts of oxidized starch, 8 to 15 parts of deionized water, 5 to 8 parts of auxiliaries and 5 to 8 parts of filler. By adding the A-type epoxy resin for modification, the steaming and boiling resistance and toughness of the A-type epoxy resin can be effectively improved, and by adding the B-type modified resin for modification, the ablation resistance of the B-type modified resin can be effectively improved. Therefore, the problems of adhesion and reduction of shear strength caused by a high-temperature environment in the use process are further solved, and the cost waste is effectively reduced.

Owner:山东格润高分子材料有限公司

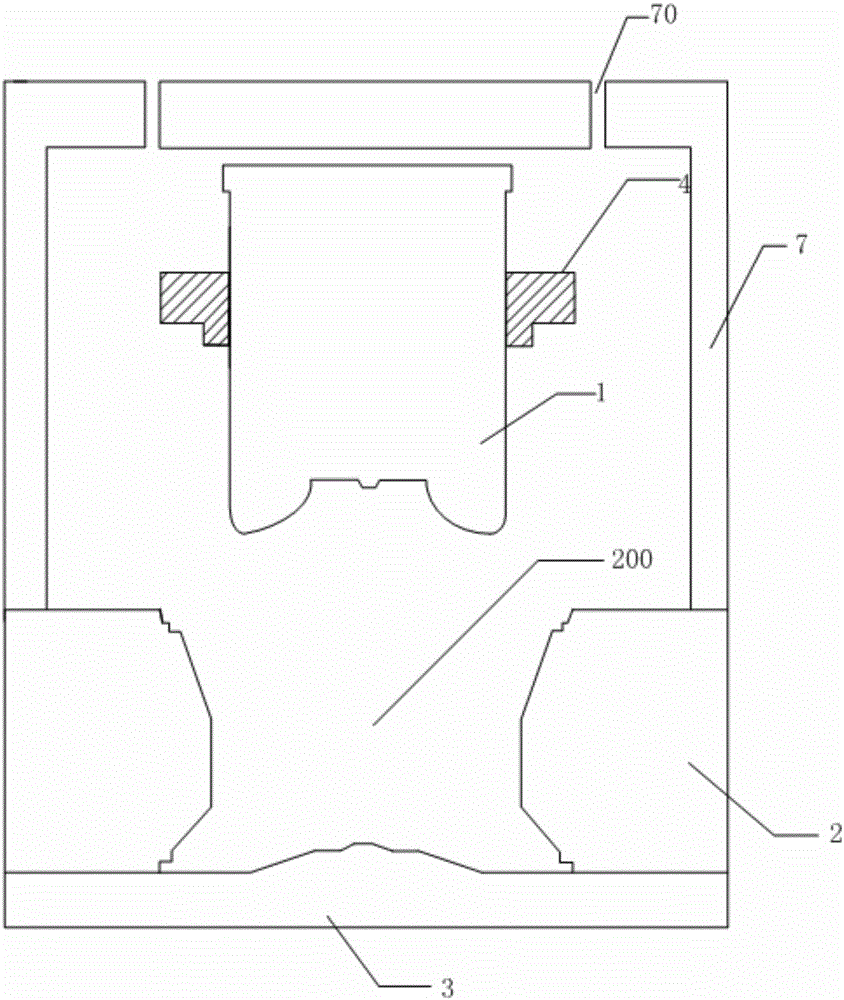

Wheel hub manufacturing equipment and wheel hub manufacturing method

The invention discloses wheel hub manufacturing equipment and a wheel hub manufacturing method for effectively improving the performance of wheel hub. The wheel hub manufacturing equipment comprises a first terrace die, a lateral die and a second terrace die. The first terrace die is arranged oppositely to the second terrace die. The first terrace die can move relative to the second terrace die. The lateral die is arranged between the first terrace and the second terrace die. The lateral die and the second terrace die form a extrusion cavity for placing a blank. A top cover of the extrusion cavity is provided with a removal sealing cover. The first terrace die is arranged in the sealing cover. The first terrace die, the lateral die and the second terrace die matched with one another. A die cavity is formed among the lateral die, the first die and the second terrace die. The sealing cover is provided with a first though hole. Vacuum treatment is carried out in the sealed cover by the first though hole. The wheel hub manufacturing equipment and wheel hub manufacturing method can be applied to aluminum alloy, magnesium alloy, carbon fiber, composite materials and other materials in manufacturing hub.

Owner:郝鑫颖

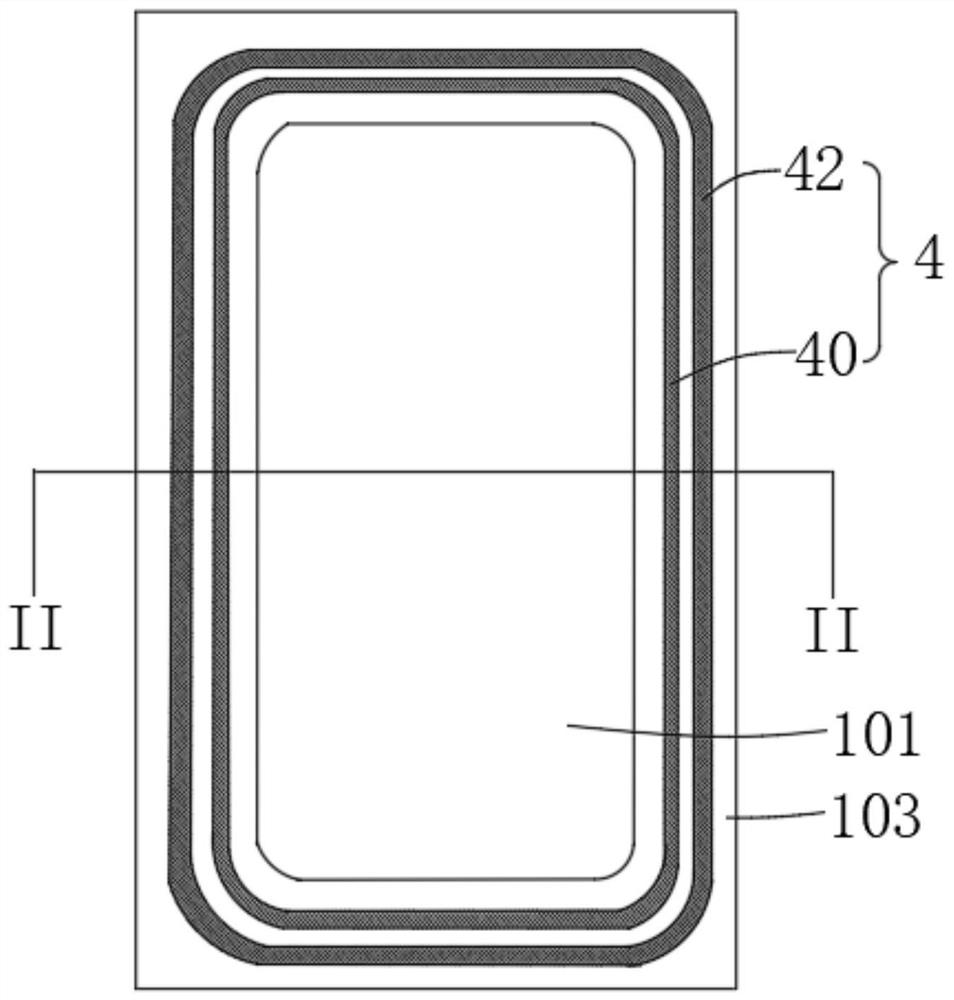

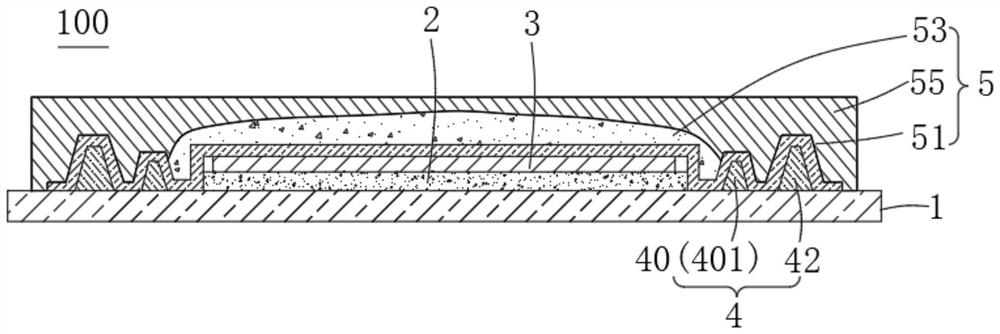

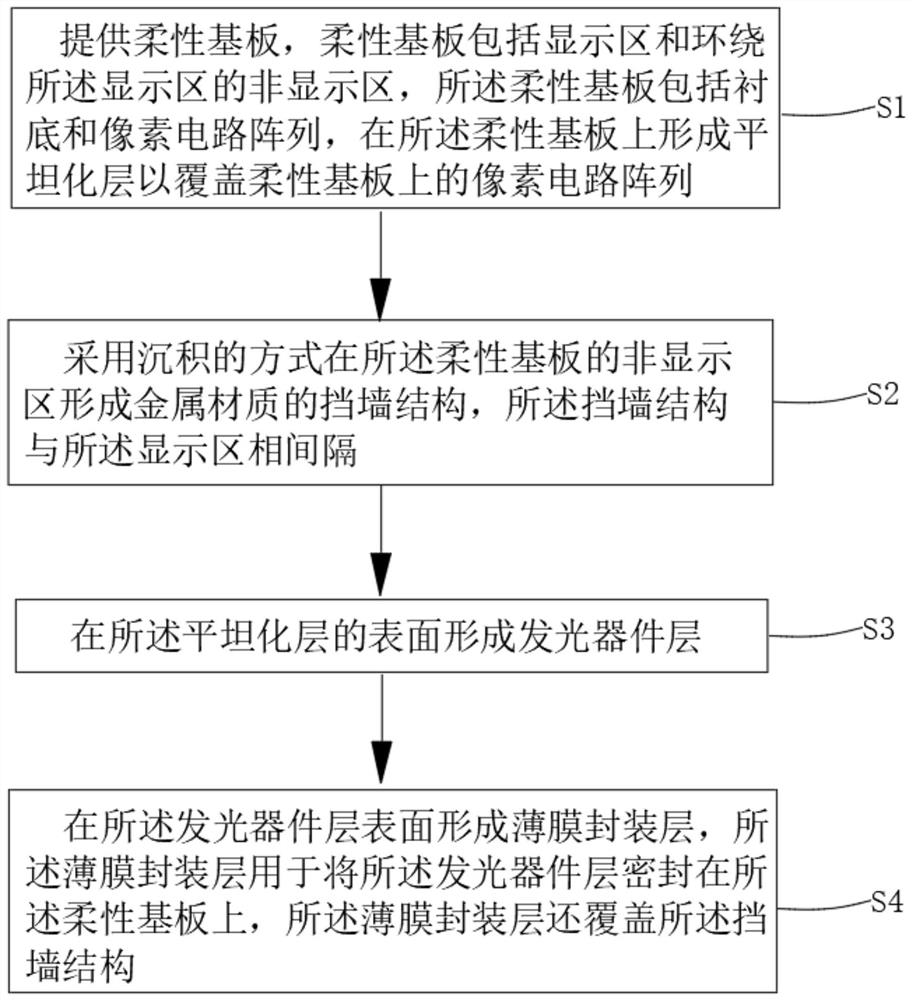

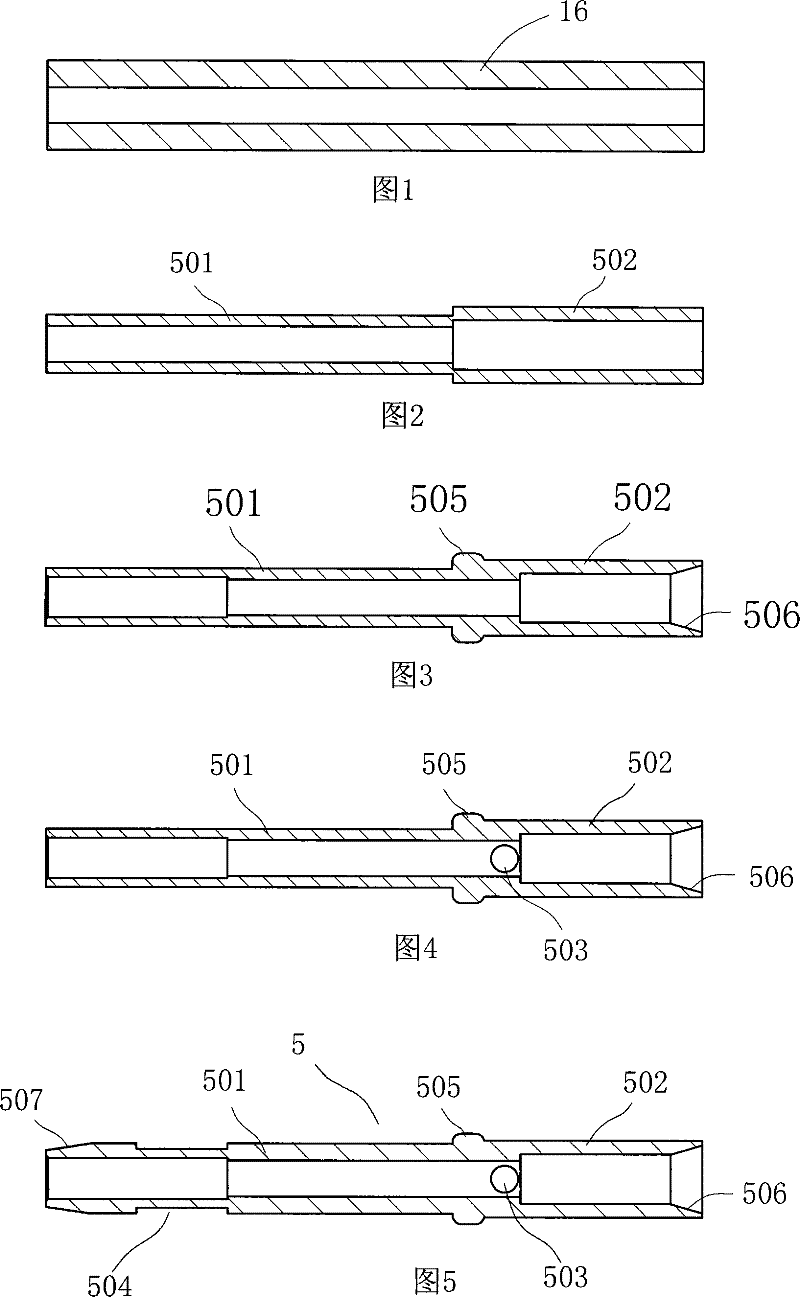

Display panel

PendingCN114420868AIncrease molecular densityHigh densitySolid-state devicesSemiconductor/solid-state device manufacturingThin membraneMechanical engineering

The invention provides a display panel which comprises a flexible substrate which comprises a display area and a non-display area surrounding the display area; the planarization layer is arranged on the surface of the flexible substrate; the light-emitting device layer is arranged on the planarization layer of the display area; the retaining wall structure is arranged in the non-display area of the flexible substrate and surrounds the display area, the retaining wall at least comprises a barrier body formed on the flexible substrate, and the barrier body is made of metal; and the thin film packaging layer covers the light emitting device layer and the retaining wall structure.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

Mold for manufacturing method of lighter nozzle

InactiveCN101216180BIncrease molecular densityNo decapitationFuel lightersProcessing costCarbon steel

The invention discloses a manufacturing method of a lighter nozzle and a mold used for the method. The manufacturing method uses low-carbon steel pipes as raw materials, and includes the steps of cutting, cold heading, drilling transverse holes, turning springboard grooves, and the like. The mold includes a support, a first mold, a return spring, a first lock, a second mold, a third mold and a fourth mold. The first mold is assembled in the through hole of the support, and there is a nozzle in it that is compatible with the finished product. The outer diameter of the front part is the same as the first through hole, the second mold is provided with the second thimble matching the first through hole, so as to form the front part of the nozzle, and the outer diameter of the rear part of the finished nozzle is set in the fourth mold Consistent bore into which a fourth ejector pin fits to shape the rear of the nozzle and the shoulder ring. The method of the invention has the advantages of simple process, high production efficiency, low raw material cost and processing cost, low material loss, etc. The mold has the advantages of simple structure and convenient use, and is especially suitable for manufacturing lighter nozzles.

Owner:徐伟明

Molten target sputtering (MTS) deposition for enhanced kinetic energy and flux of ionized atoms

ActiveUS10947639B2Increase kinetic energyIncrease flux densityPolycrystalline material growthElectric discharge tubesSputteringChemical physics

Various embodiments provide Molten Target Sputtering (MTS) methods and devices. The various embodiments may provide increases in the kinetic energy, increases in the energy latency, and / or increases in the flux density of molecules for better crystal formation at low temperature operation. The various embodiment MTS methods and devices may enable the growth of a single crystal Si1-xGex film on a substrate heated to less than about 500° C. The various embodiment MTS methods and devices may provide increases in the kinetic energy, increases in the energy latency, and / or increases in the flux density of molecules without requiring the addition of extra systems.

Owner:NASA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com