Cigarette lighter nozzle manufacture method and mould for the method

A manufacturing method and technology for lighters, applied in the field of lighter parts, can solve the problems of easy corrosion of zinc-aluminum gas nozzles, difficult processing, and high rate of broken ends, and achieve the advantages of less manufacturing technical processes, stable product quality, and reduced material loss. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

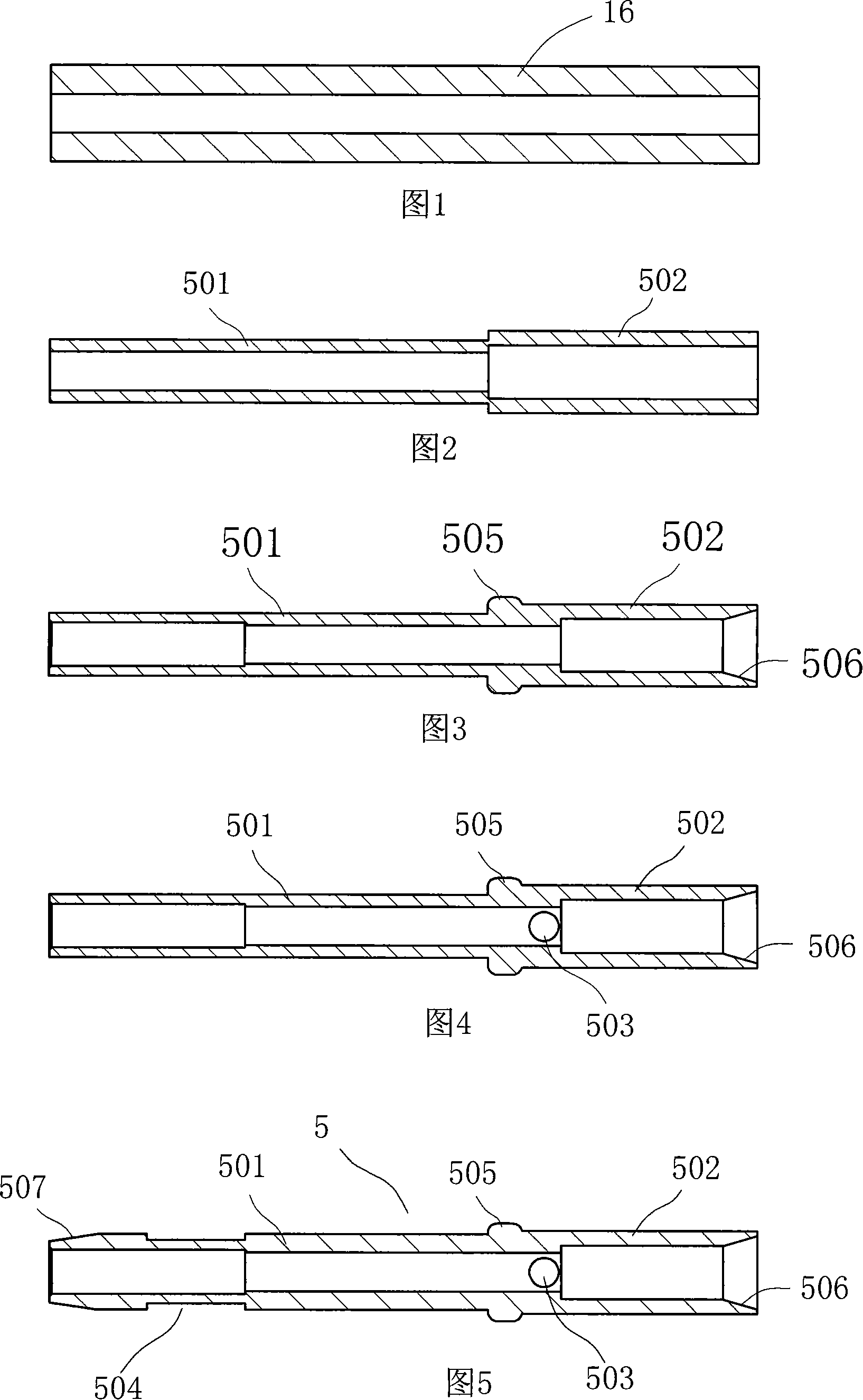

[0053] As shown in Figure 5, the nozzle 5 has a front part 501 with a smaller outer diameter, a rear part 502 with a larger outer diameter, a transverse hole 503 and a springboard groove 504, and the junction of the front part 501 and the rear part 502 has a rear part with a smaller outer diameter. 502 a larger shoulder ring 505 , the rear end of the nozzle 5 also has an inner hole chamfer 506 , and the front end of the nozzle 5 has an outer chamfer 507 .

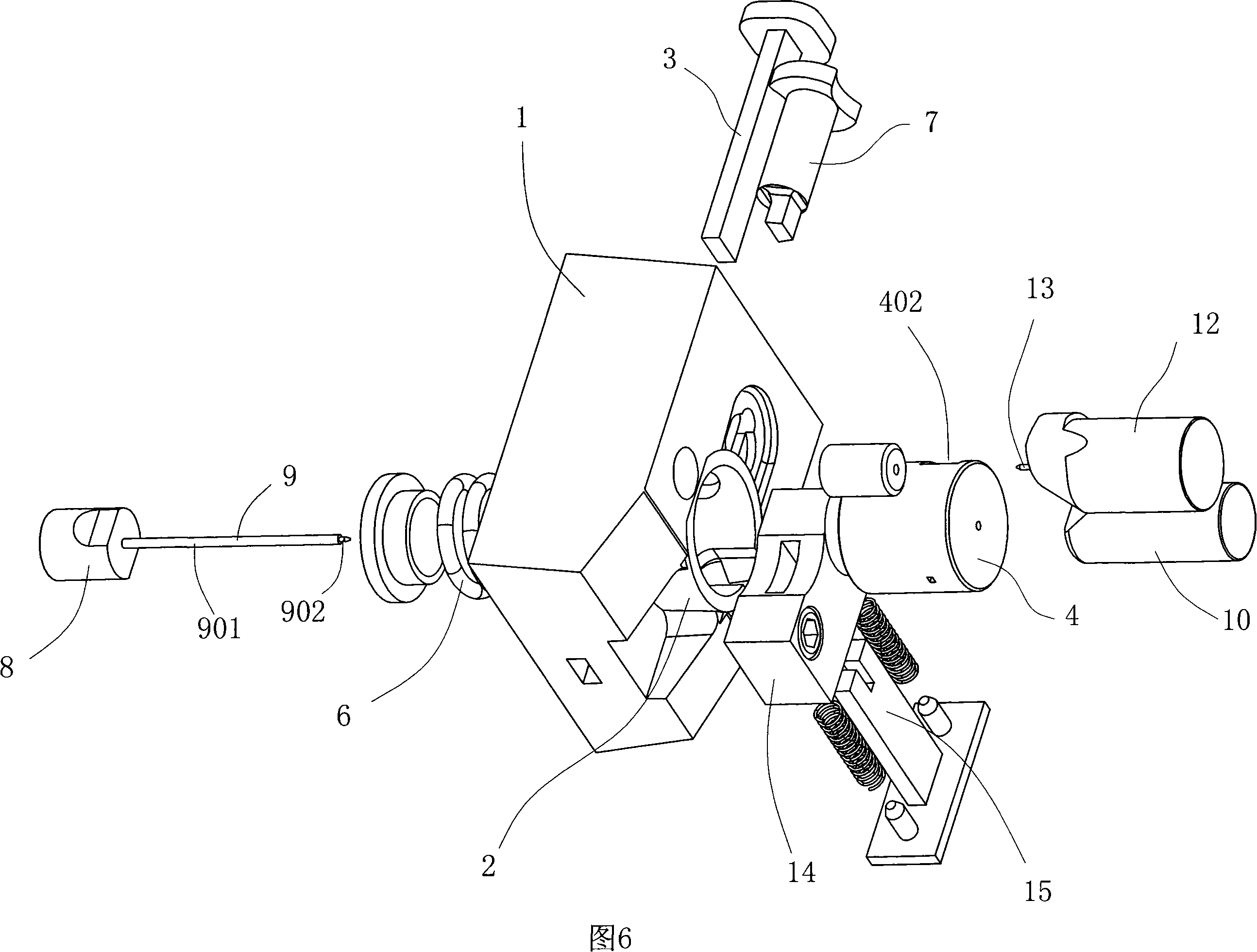

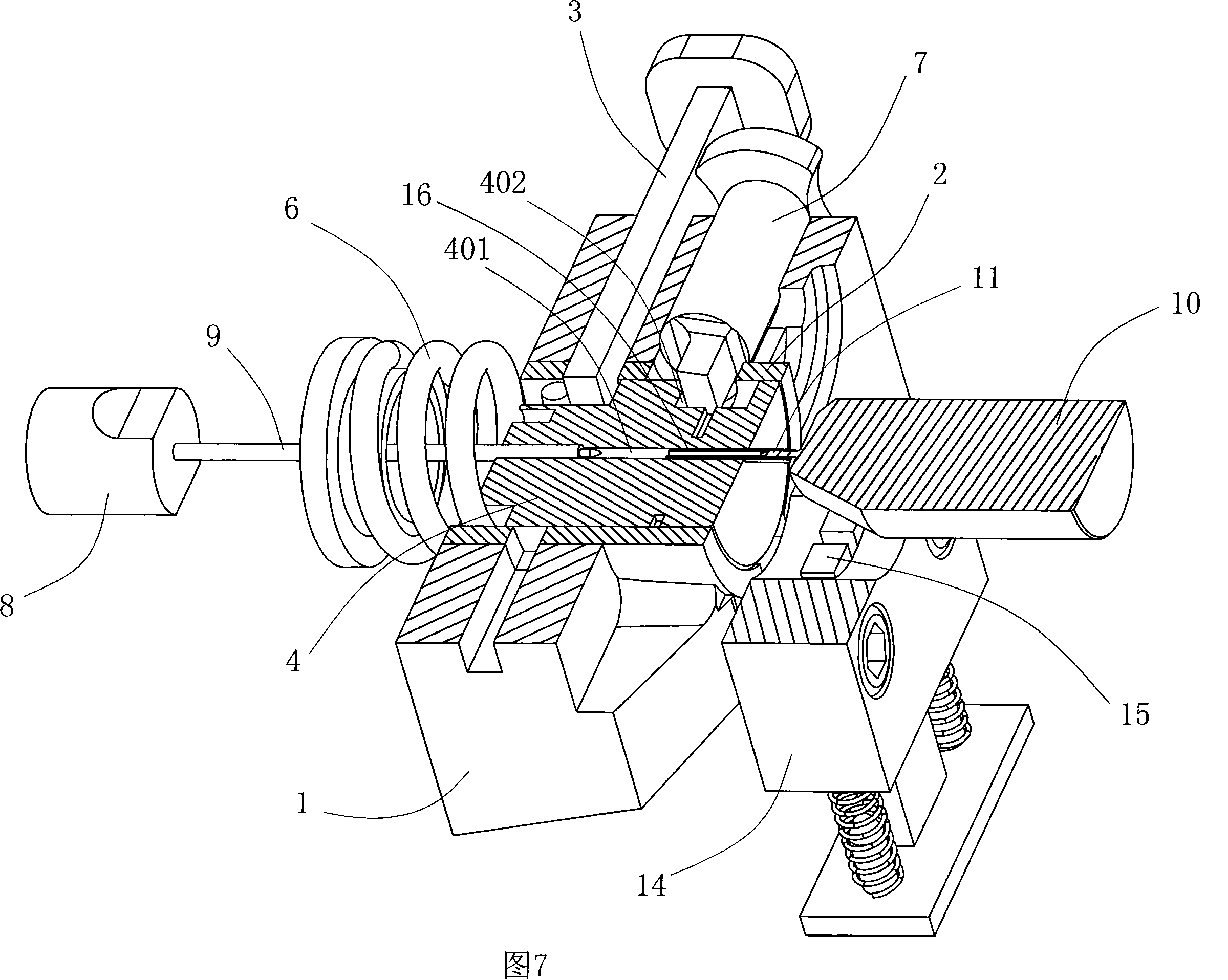

[0054] As shown in Fig. 6~Fig. 16, the structure of mold of the present invention is as follows:

[0055] It includes:

[0056] A seat, the seat includes a seat body 1 and a sleeve 2 embedded in the seat body 1, the inner cavity of the sleeve 2 is provided with a through hole, and the seat body 1 is also provided with a 2. The second lock 3 fixed in the seat body 1;

[0057] A first mold...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com