Cooking-resistant modified polyurethane adhesive and preparation method thereof

A technology of polyurethane adhesives and cooking resistance, which is applied in the direction of polyurea/polyurethane adhesives, adhesives, polymer adhesive additives, etc., can solve the problems that polyurethane adhesives cannot be widely used, harmful asbestos to human body, etc., and achieve reduction of human silicosis, Effect of improving retort resistance and good ablation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

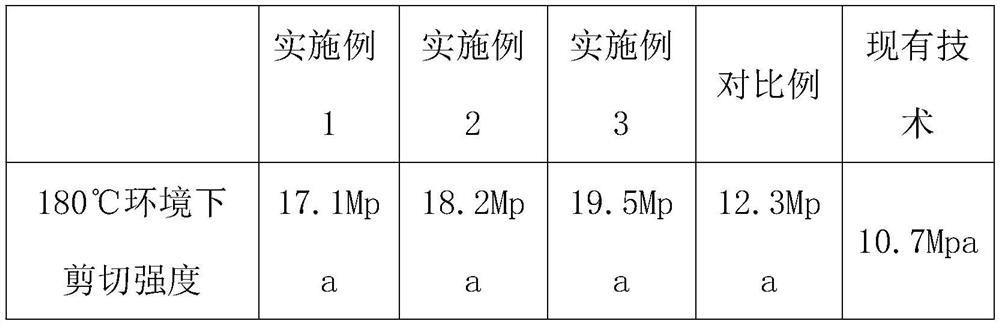

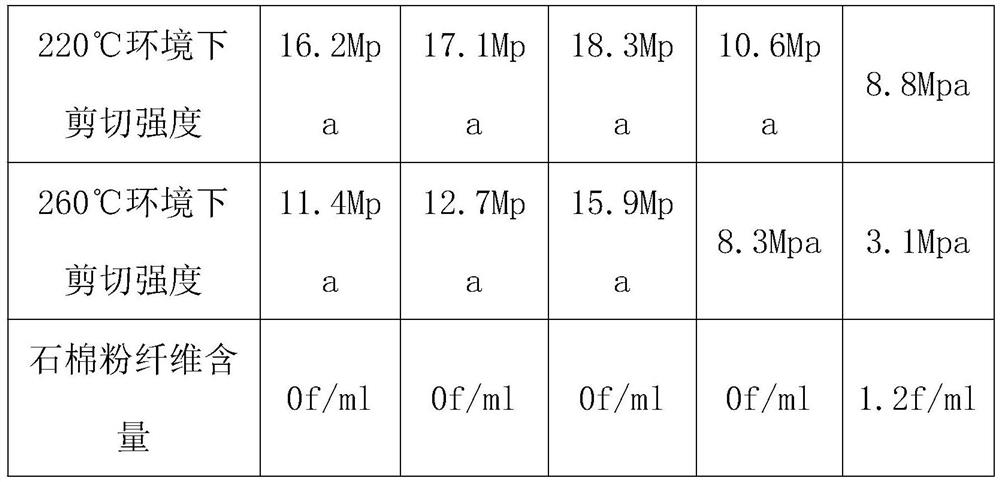

Embodiment 1

[0046] A retort-resistant modified polyurethane adhesive. The composition of the retort-resistant modified polyurethane adhesive includes: 23 parts of oxalic acid, 12 parts of diethylene glycol, 14 parts of ethylene glycol, diphenylmethane diiso 9 parts of chlorate ester, 4 parts of ethyl acetate, 22 parts of A-type modified epoxy resin, 5 parts of oxidized starch, 12 parts of deionized water, 7 parts of auxiliary agent, and 6 parts of filler.

[0047] Type A modified epoxy resin includes the following components: 40 parts of epoxy resin, 45 parts of silicone, 15 parts of amino silicone oil, and 4 parts of water;

[0048] Type A modified epoxy resin preparation steps are as follows:

[0049] A1. Put 40 parts of epoxy resin into the reactor and heat to 95°C;

[0050] A2. Take 45 parts of organic silicon for crushing, and take the crushed organic silicon particles for sieving;

[0051] A3. Add the sieved silicone into the reactor, add 4 parts of water, and heat to 120°C;

[0...

Embodiment 2

[0067] A retort-resistant modified polyurethane adhesive. The composition of the retort-resistant modified polyurethane adhesive includes: 23 parts of oxalic acid, 12 parts of diethylene glycol, 14 parts of ethylene glycol, diphenylmethane diiso 9 parts of chlorate ester, 4 parts of ethyl acetate, 22 parts of A-type modified epoxy resin, 23 parts of B-type modified epoxy resin, 5 parts of oxidized starch, 12 parts of deionized water, 7 parts of additives, 6 parts of filler share.

[0068] Type A modified epoxy resin includes the following components: 40 parts of epoxy resin, 45 parts of silicone, 15 parts of amino silicone oil, and 4 parts of water;

[0069] Type A modified epoxy resin preparation steps are as follows:

[0070] A1. Put 40 parts of epoxy resin into the reactor and heat to 95°C;

[0071] A2. Take 45 parts of organic silicon for crushing, and take the crushed organic silicon particles for sieving;

[0072] A3. Add the sieved silicone into the reactor, add 4 pa...

Embodiment 3

[0103] A retort-resistant modified polyurethane adhesive. The composition of the retort-resistant modified polyurethane adhesive includes: 25 parts of oxalic acid, 15 parts of diethylene glycol, 15 parts of ethylene glycol, diphenylmethane diiso 5 parts of chlorate ester, 4 parts of ethyl acetate, 20 parts of A-type modified epoxy resin, 25 parts of B-type modified epoxy resin, 5 parts of oxidized starch, 10 parts of deionized water, 5 parts of additives, 5 parts of filler share.

[0104] Type A modified epoxy resin includes the following components: 40 parts of epoxy resin, 45 parts of silicone, 15 parts of amino silicone oil, and 4 parts of water;

[0105] Type A modified epoxy resin preparation steps are as follows:

[0106] A1. Put 40 parts of epoxy resin into the reactor and heat to 95°C;

[0107] A2. Take 45 parts of organic silicon for crushing, and take the crushed organic silicon particles for sieving;

[0108] A3. Add the sieved silicone into the reactor, add 4 pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com