High-precision optical fiber detecting method for roller path curved surface in ball nut

A ball nut and optical fiber detection technology, which is applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems that the helix angle cannot be detected, the processing quality of the ball nut cannot be fully evaluated, and the measurement results cannot effectively explain the accuracy of the measured object, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

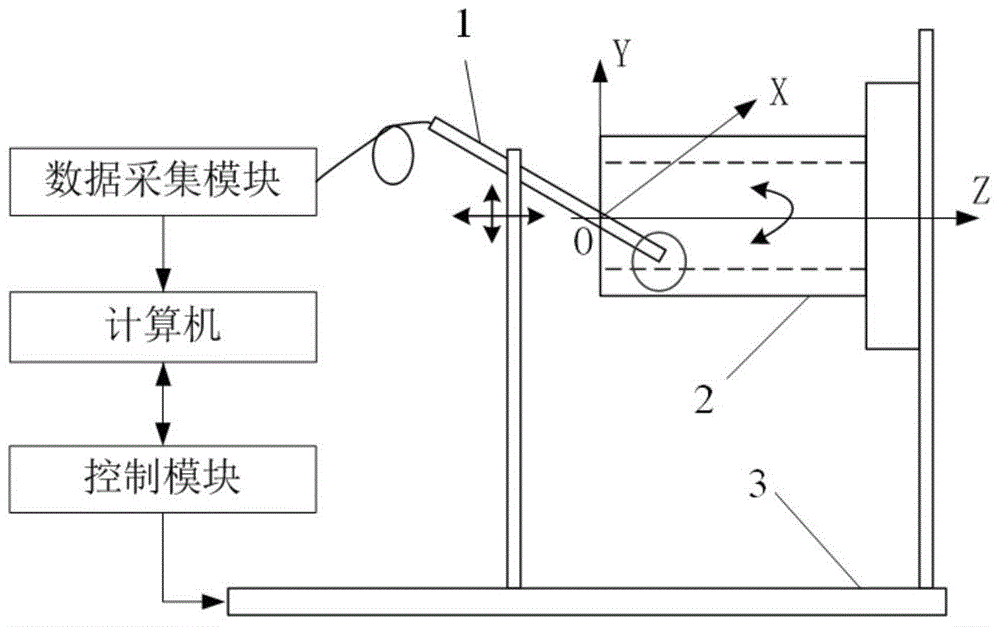

[0042] (1) Developed a set of high-precision optical fiber detection platform for the inner raceway surface of the ball nut, and described the composition and detection method of the platform in detail;

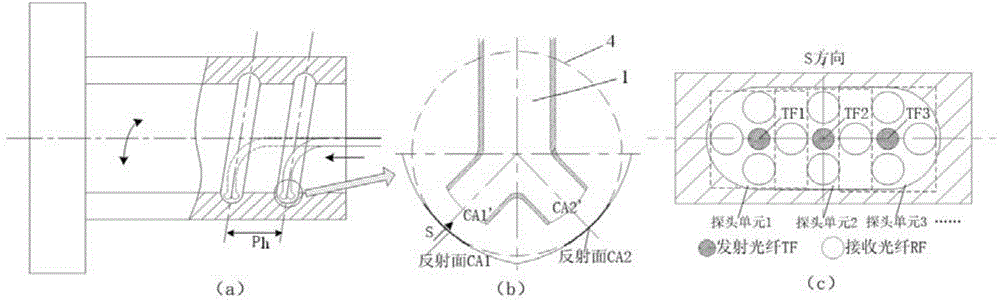

[0043] (2) Then, based on the shape characteristics of the inner raceway surface of the ball nut, a special expandable optical fiber sensor probe was designed, and the mathematical model of the light intensity modulation curve of the probe unit in the probe was established;

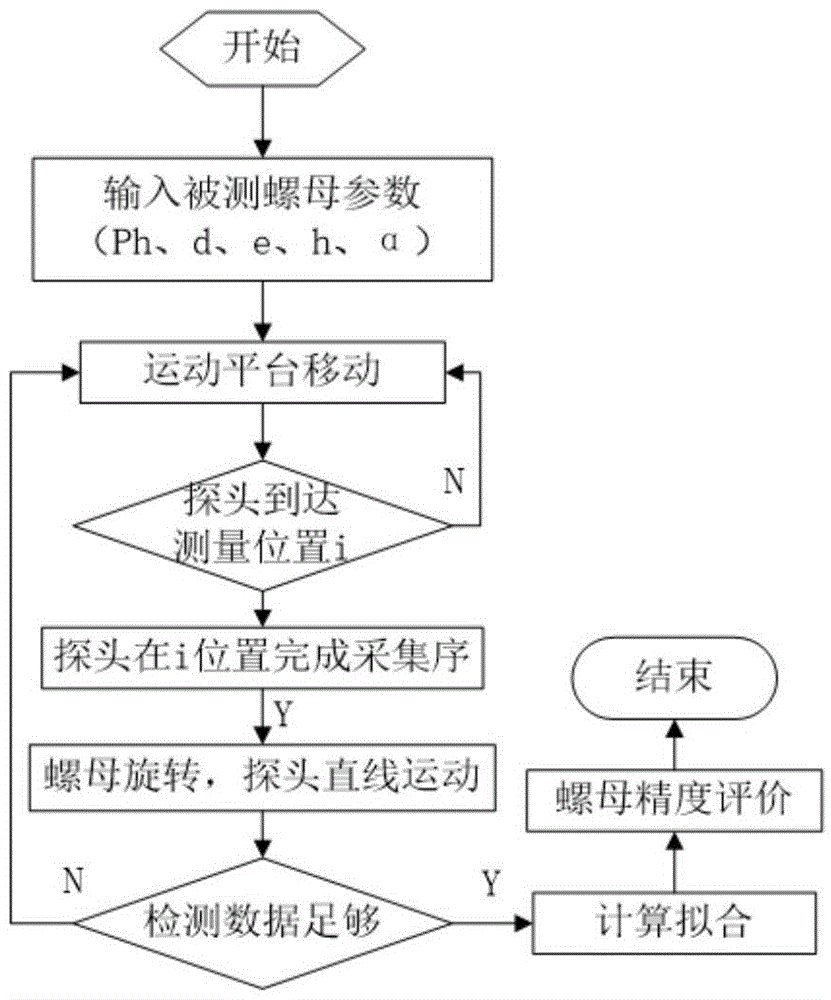

[0044] (3) Finally, combined with the characteristics of the inner raceway of the ball nut to be tested, a detection method for the inner raceway surface of the ball nut is given.

[0045] Described step (1) comprises following specific content:

[0046] 1) The system composition of the high-precision optical fiber detection platform facing the inner raceway surface of the ball...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com