Concrete structure anti-permeability quantitative design method with consideration of load effect

A technology for concrete structure and quantitative design, applied in measurement devices, permeability/surface area analysis, suspension and porous material analysis, etc. Considering the impact of the impermeability of concrete and other issues, to achieve the effect of high practicability, improving comprehensiveness and reliability, and comprehensive design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

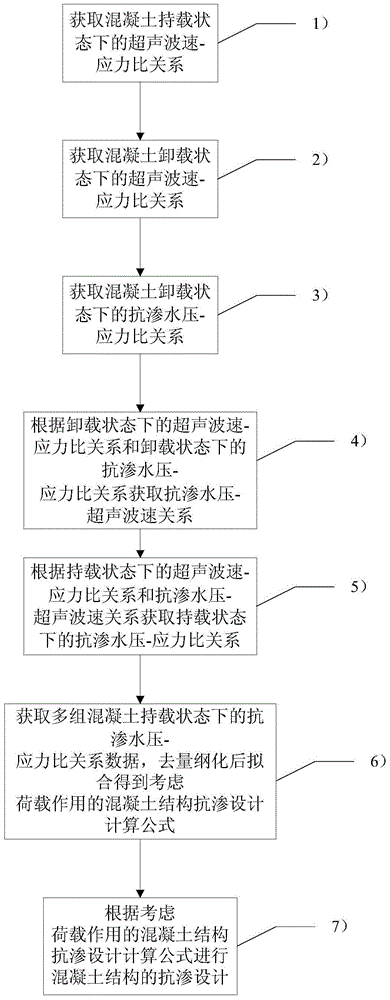

[0036] Such as figure 1 As shown, a concrete structure anti-seepage design method considering the load action includes the following steps:

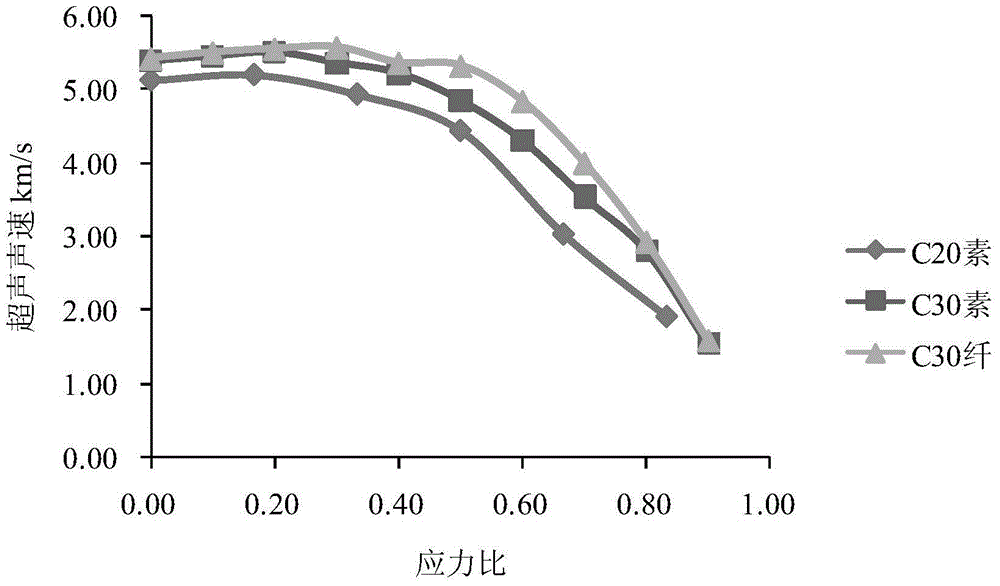

[0037] 1) Test the "ultrasonic velocity-stress ratio" relationship of concrete under load, such as image 3 Shown, denoted as the relationship ①;

[0038] 2) Test the "ultrasonic velocity-stress ratio" relationship in the unloaded state of concrete, such as Figure 4 As shown, it is recorded as the relationship ②;

[0039] 3) Test the relationship of "impervious water pressure-stress ratio" under the unloading state of concrete, such as Figure 5 As shown, it is recorded as the relationship ③;

[0040] 4) According to the relationship ②③, the "stress ratio" is used as the intermediate quantity for derivation, and the relationship of "impermeable water pressure-ultrasonic velocity" of concrete can be obtained, which is recorded as the relationship ④;

[0041] 5) According to the relationship ①④, using the “ultrasonic velocity” as an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com