Flue gas waste heat recovery system optimization design method considering all-working-condition external parameter change

A flue gas waste heat recovery system technology, applied in the knowledge-based model computer system, multi-objective optimization, design optimization/simulation, etc., can solve problems that are not conducive to the efficient operation of the flue gas waste heat recovery system, and achieve the design configuration Improvement, flexible methods, and the effect of large comprehensive technical and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

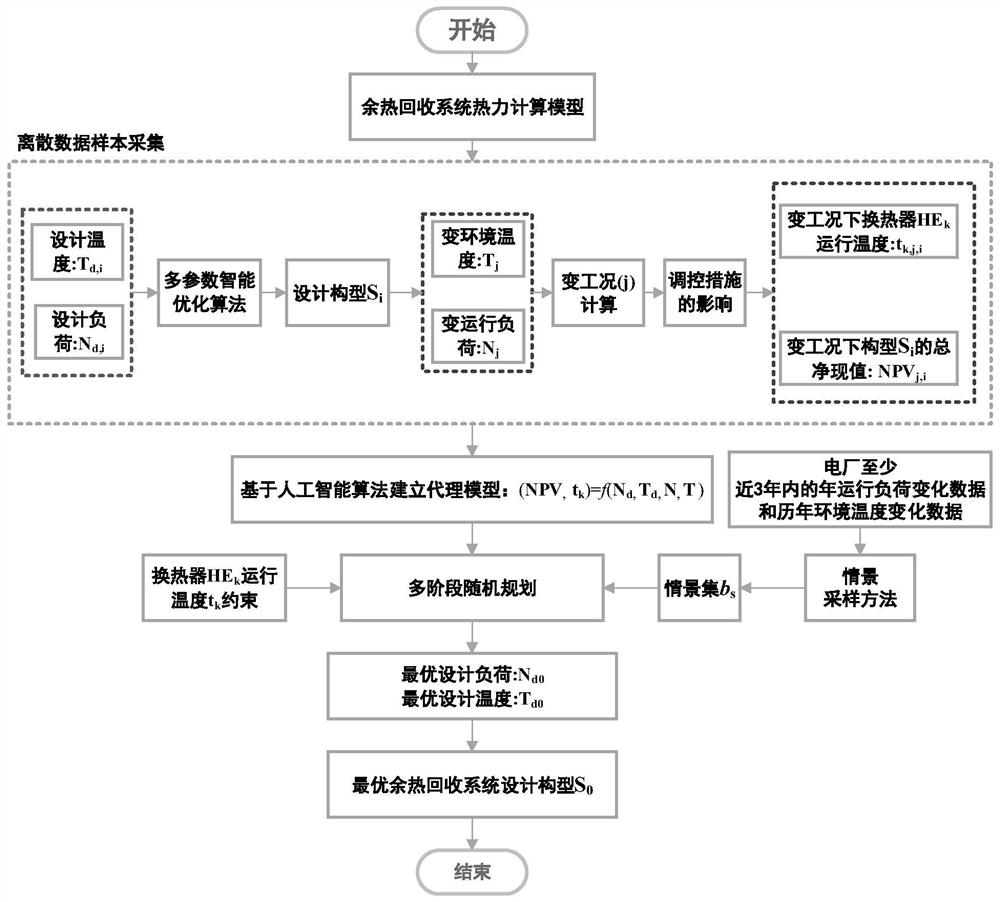

[0033] Such as figure 1 As shown, the present invention considers the optimization design method of flue gas waste heat recovery system considering the change of external parameters in all working conditions. The flue gas waste heat recovery system consists of h heat exchangers HE k (k=1~h) and pipeline valve system connection between heat exchangers;

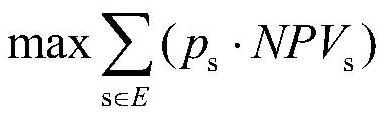

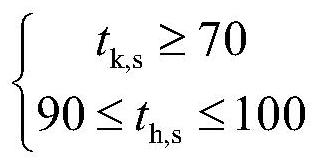

[0034] The optimal design method of the flue gas waste heat recovery system is to obtain the design configuration S of the waste heat recovery system with the largest comprehensive technical and economic benefits under the condition of changing external parameters in all working conditions 0 is the final optimization goal; at each stage, the optimization goal is to maximize the system's technical economy; in the stage of using the thermal calculation model to collect discrete data sam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com