An adjustable constant current drive circuit for semiconductor laser with temperature compensation

A temperature compensation, constant current drive technology, applied in semiconductor lasers, lasers, laser parts and other directions, can solve problems such as laser instability, and achieve the effect of completely practical structure, improved instability, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

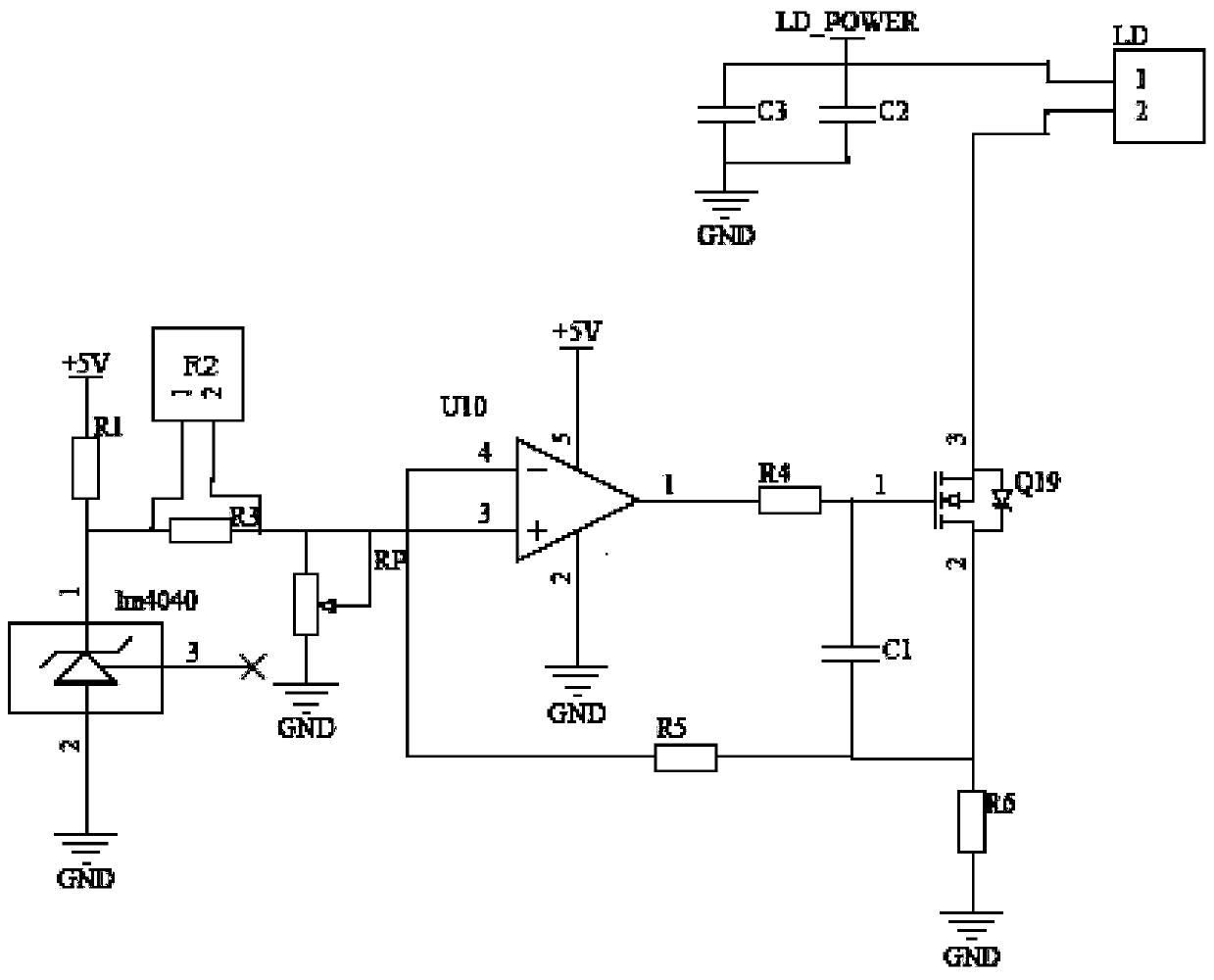

[0013] see figure 1 Circuit schematic diagram, this circuit is composed of an operational amplifier U10, a thermistor R2, a MOS transistor Q19, a three-stage voltage regulator lm4040, two power supplies, several resistors and capacitors.

[0014] The three-terminal voltage regulator lm4040 is powered, and the output is connected in series to the positive input of the operational amplifier U10. The thermistor R2 and R3 are connected in parallel and then connected in series to the output of the three-stage voltage regulator, and then connected to the positive input of the operational amplifier. terminal, the potentiometer RP is connected to the positive input terminal of the operational amplifier U10 and then grounded.

[0015] In particular, the thermistor R2 is an NTC type resistor with a negative temperature coefficient, its characteristic is a pure resistance value, and its resistance value changes linearly with temperature. In the implementation case, it is mounted on the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com