Filter element and filter bowl for compressed air filter

A compressed air and filter technology, applied in the fields of dispersed particle filtration, chemical instruments and methods, separation methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

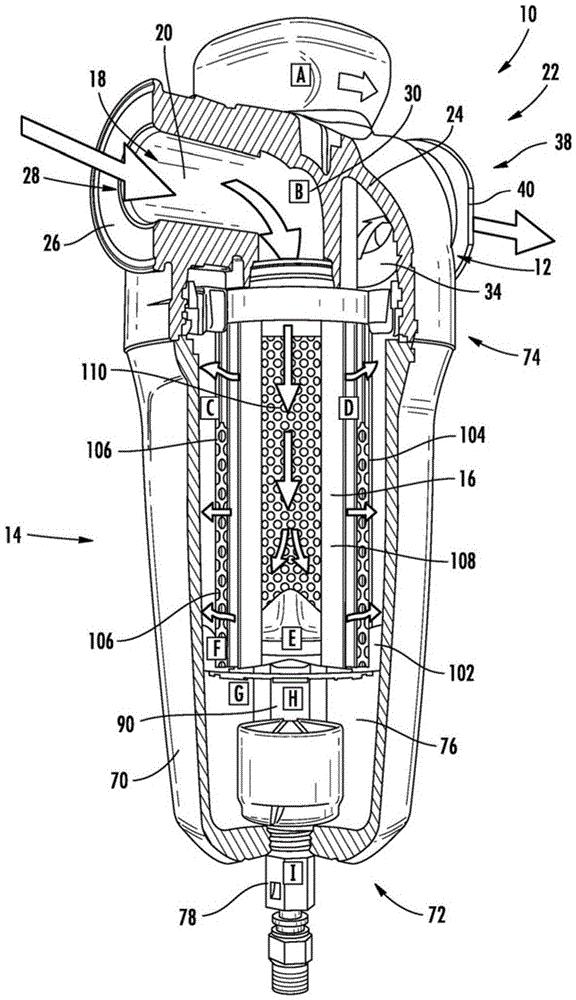

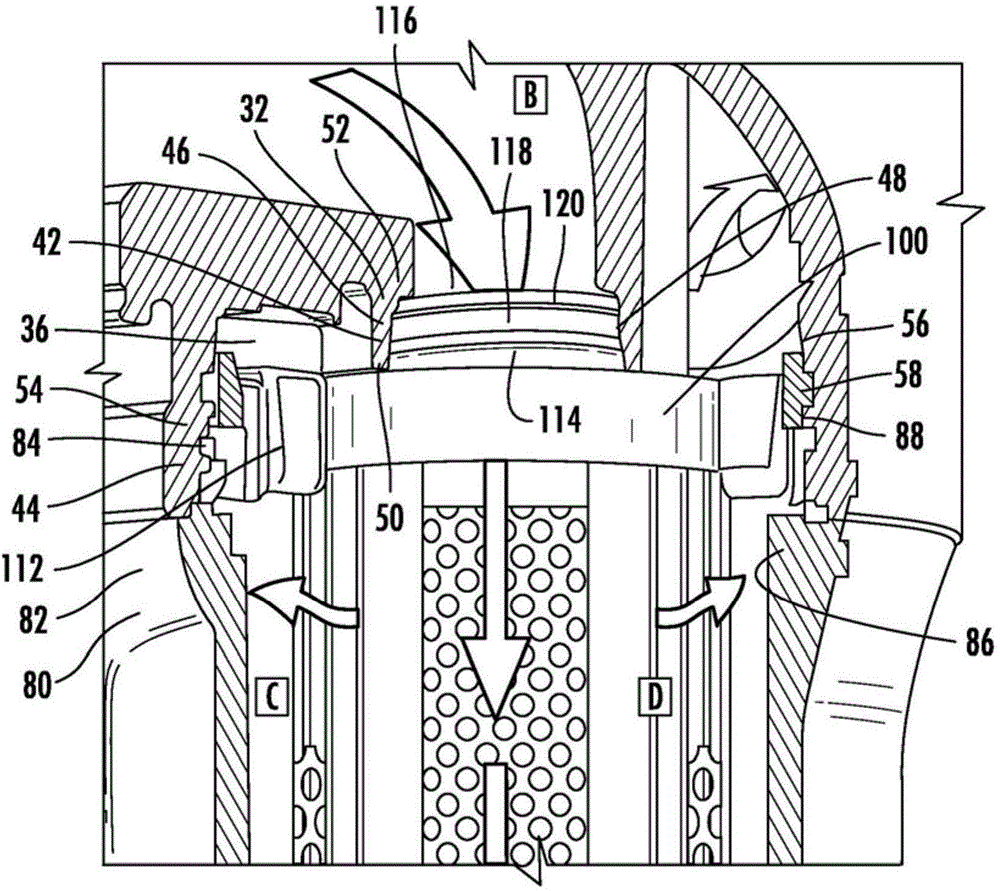

[0016] 1 and 2 show a prior art compressed air filter 10 . The compressed air filter 10 includes a filter head 12 , a filter body 14 and a filter element 16 . The filter head 12 includes an inlet channel 18 formed by an inlet wall 20 and an outlet channel 22 formed by an outlet wall 24 . The inlet channel 18 includes a first end 26 in fluid communication with the inlet opening 28 and a second end 30 in fluid communication with a first filter element opening 32 ( FIG. 2 ). Outlet channel 22 includes a first end 34 in fluid communication with a second filter element opening 36 ( FIG. 2 ) and a second end 38 in fluid communication with outlet opening 40 .

[0017] The filter head 12 further includes a filter element connector 42 and a filter body connector 44 . The filter element connector 42 includes a first cylindrical collar 46 that forms the first filter element opening 32 . A first cylindrical collar 46 extends downwardly from the filter head 12 and includes an inner cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com