Closestool cover plate hinged cover-turning mechanism

A technology for toilet lids and hinges, which is applied in the direction of hinges with pins, power control mechanisms, wing fan control mechanisms, etc., which can solve the unfavorable simplicity of the appearance of the toilet cover, the large impact on the appearance of the toilet cover, and the unfavorable toilet cover. Cleaning work and other issues, to achieve the effect of facilitating mass production, compact structure, and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

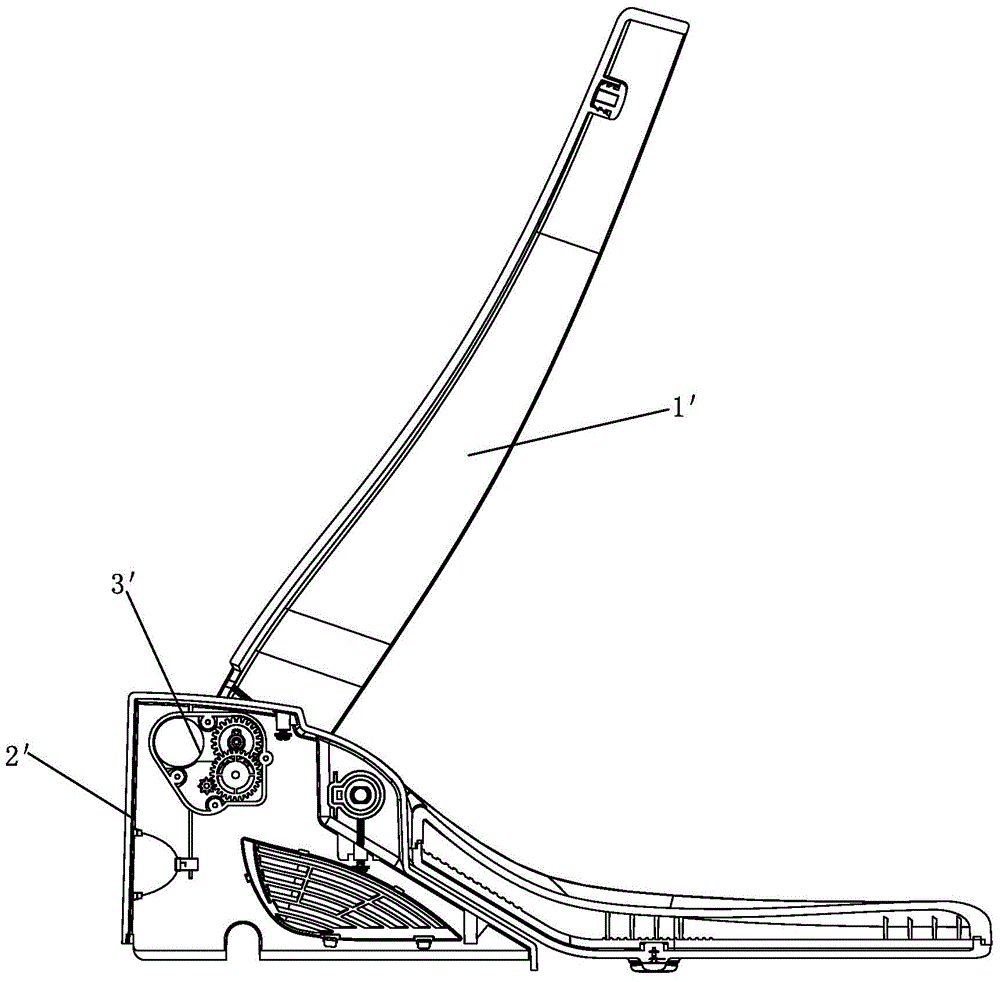

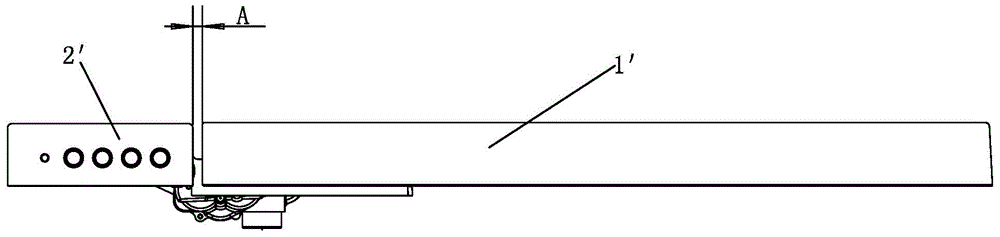

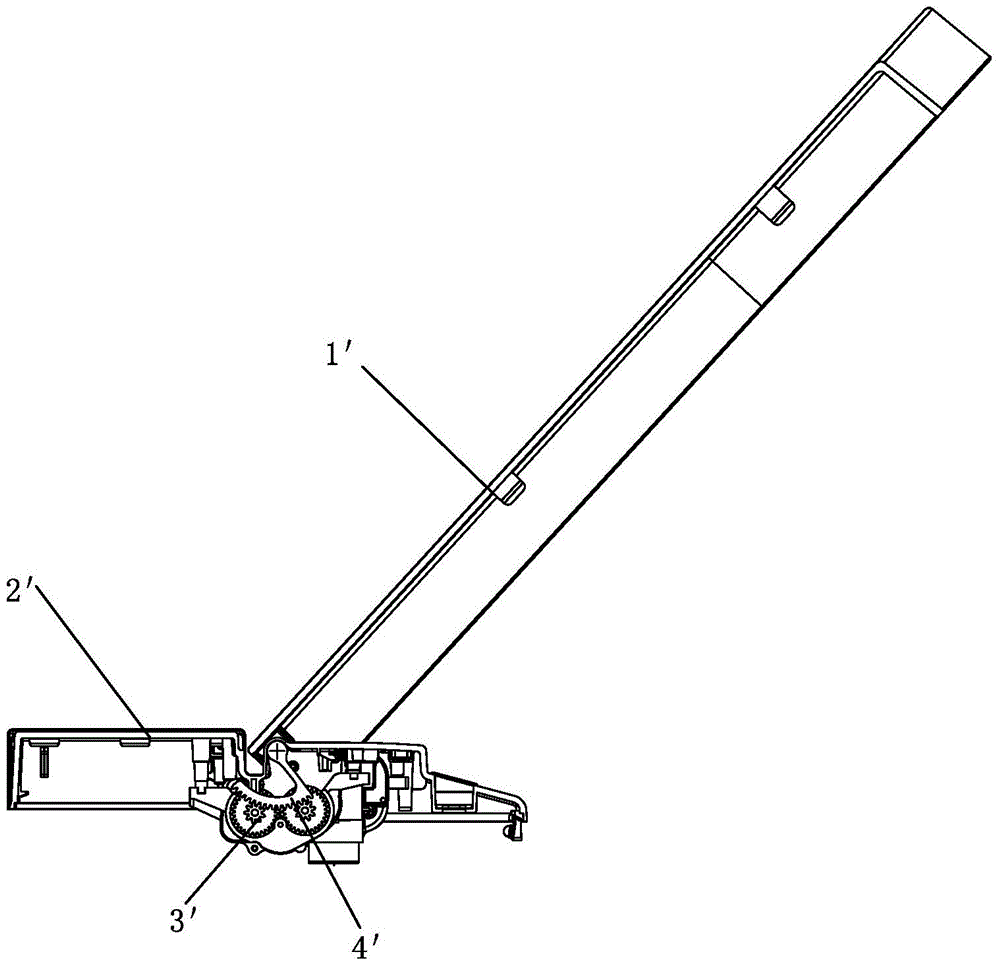

[0044] See Figure 4-Figure 10As shown, a toilet cover hinge flip mechanism of the present invention includes a body and a toilet cover, and also includes two hinge modules 3 (the number of hinge modules 3 is not limited to two, and can also be one or more than two) . The main body is preferably a toilet back cover 2 (of course, it can also be a toilet seat, etc.), and the toilet cover includes a toilet cover 1 (of course, the toilet cover can also include a toilet seat, or both the toilet cover and the toilet seat) , the toilet top cover 1 is connected with the toilet back cover 2 through the two hinge modules 3, when the toilet top cover 1 is turned up, the toilet top cover 1 gradually pulls away from the toilet back cover 2 with the angle of turning up. gap. When the toilet cover is closed, the gap between the toilet cover and the body gradually decreases with the closing angle.

[0045] As a preference, each hinge module 3 above includes a front support 31 , a rear supp...

Embodiment 2

[0054] See Figure 11 As shown, a toilet lid hinge flip mechanism of the present invention differs from Embodiment 1 in that its transmission mechanism includes a drive shaft coaxially linked with the second end of the first hinge crank 32; it also includes A gear box 8, the gear box 8 can be installed on the toilet back cover 2, and the output shaft of the gear box 8 constitutes a drive shaft. Or, a slow falling mechanism can also be used to replace the gear box 8, and the output shaft of the slow falling mechanism constitutes a drive shaft.

[0055] In the toilet cover hinge flip mechanism of the present invention, when the gear box 8 drives the second end of the first hinge crank 32 to rotate counterclockwise, the first hinge crank 32 pushes the front support 31 to move forward and turn upward, and at the same time, The second hinge crank 33 gradually protrudes from the rear support 34 . When the gear box 4 drives the second end of the first hinge crank 32 to rotate clock...

Embodiment 3

[0057] See Figure 12 As shown, the toilet cover hinge flip mechanism of the present invention differs from the second embodiment in that its drive shaft is coaxially linked with the second end of the second hinge crank 33 . Similarly, the output shaft of the gearbox 8 (or the slow drop mechanism) can be used to form the drive shaft, or the output shaft of the gearbox 8 (or the slow drop mechanism) can be fixedly connected to the drive shaft.

[0058] In a toilet lid hinge flip mechanism of the present invention, when the gear box 8 drives the second end of the second hinge crank 33 to rotate counterclockwise, the sliding shaft at the first end of the second hinge crank 33 moves along the cavity of the rear support 34 The two-axis chute moves forward, thereby pushing the front support 31 to move forward; during the forward movement of the front support 31, the first hinge crank 32 rotates, and the sliding shaft at one end moves along the front support 31. The two axial slidin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com