A pretreatment method for subway tunnels before excavation

A pretreatment and tunneling technology, applied in soil protection, sheet pile walls, construction, etc., can solve problems such as slow excavation speed, damage to buildings, pipeline fractures, etc., and achieve the effect of reducing interference, short construction period, and small disturbance to residents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

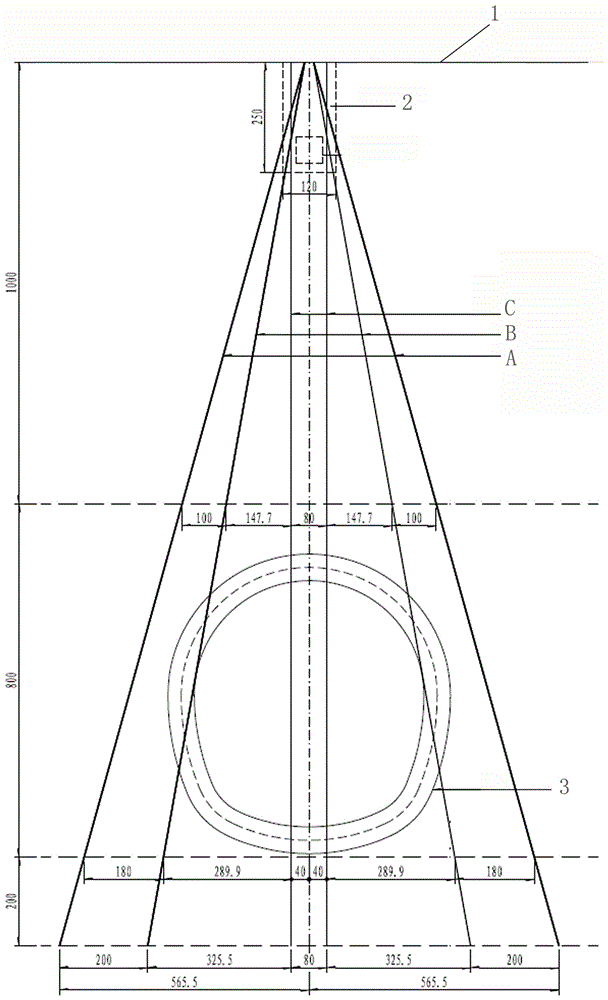

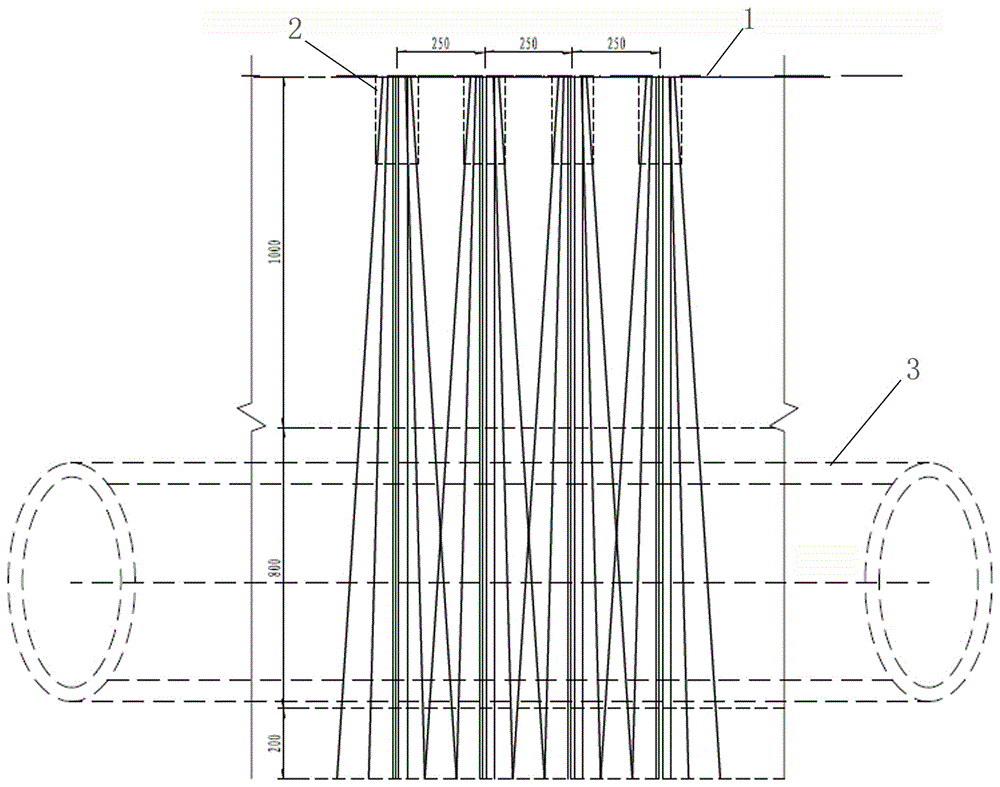

[0041] Taking the ground pre-grouting project of Changsha Metro Line 1 (Huangxing Road) as an example, this method will be further explained in conjunction with the attached drawings.

[0042] The project requires:

[0043] 1. Make sure to avoid underground pipelines in the site;

[0044] 2. During the grouting process, it is necessary to avoid causing destructive uplift to surrounding buildings and underground pipelines;

[0045] 3. Stop the underground water passing through each soil layer of the subway tunnel 3, so that the excavation of the tunnel 3 will prevent water and sand from gushing;

[0046] 4. Fast construction and controllable construction period.

[0047] The concrete implementation of this project is as follows:

[0048] Such as Figure 1 to Figure 4 As shown, the center line of the ground corresponding to the center line of the tunnel 3 is calibrated on the ground 1, and the trenches 2 of 1.2m×1.2m are arranged at a distance of 2.5m on the center line of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com