A kind of high-performance non-polar rubber material and preparation method thereof

A technology of non-polar rubber and polar rubber, which is applied in the field of high-performance non-polar rubber materials and its preparation, and can solve the problems of limited energy dissipation and enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

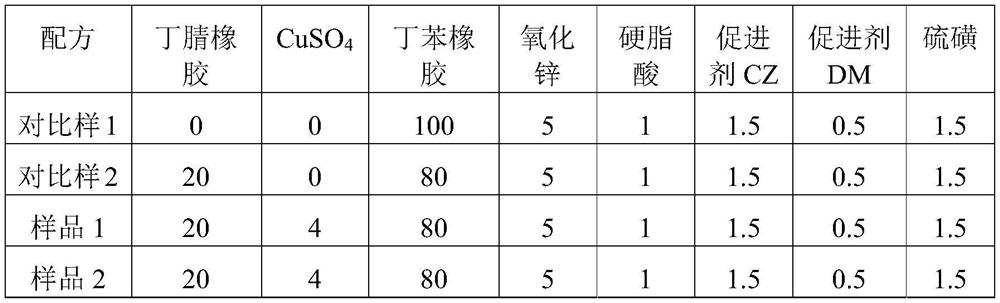

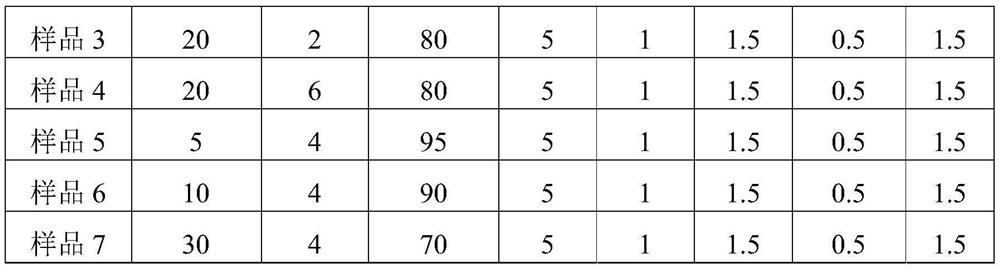

[0038]Add nitrile butadiene rubber, copper sulfate (CuSO), and styrene-butadiene rubber to an internal mixer and mix at room temperature for 20 minutes to obtain a mixed rubber; heat and press the mixed rubber at 180 degrees for 20 minutes; Under room temperature conditions, rubber activator zinc oxide and stearic acid, accelerator CZ (N-cyclohexyl-2-benzothiazole sulfenamide), accelerator DM (2,2'-dithiodibenzothiazole ), and sulfur were sequentially added to the above-mentioned rubber mixture, and the mixing time was 8 minutes; the obtained rubber mixture was vulcanized at 150°C according to the normal curing time, and the addition amount of CuSO, the ratio of the two phases and the hot-pressing temperature were changed to obtain Samples 1-7. The specific formula is shown in Table 1 (Table 1 is the formula table of the comparison sample and the sample), and the unit in Table 1 is g, wherein, the hot-pressing temperature of sample 1 is 170° C., and the hot-pressing temperatur...

Embodiment 2

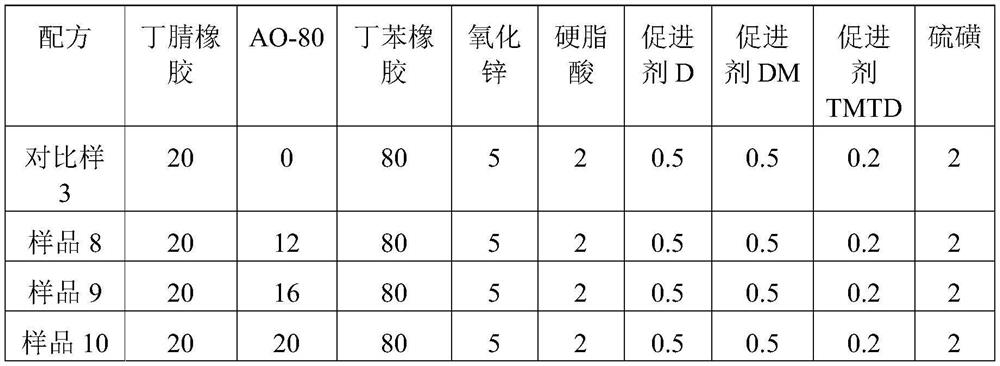

[0043] Add nitrile rubber, hindered phenol AO-80, and styrene-butadiene rubber to an internal mixer in sequence and mix for 10 minutes at room temperature, then raise the temperature to 135°C and mix for 10 minutes to obtain a mixed rubber; in the open mixer, mix the rubber at room temperature Activator zinc oxide, stearic acid, accelerator D (diphenylguanidine), accelerator DM (2, 2'-dithiodibenzothiazole), accelerator TMTD (C 6 h 12 N 2 S 4 ) and sulfur were sequentially added to the above rubber compound, and the mixing (opening) time was 10 minutes; the obtained compound rubber was vulcanized at 150°C according to the normal curing time, and by changing the amount of AO-80 added and the ratio of the two phases, Obtain comparative sample 3 and sample 8-10; Concrete formula is as shown in table 2 (table 2 is comparative sample and embodiment formula parameter list), and the unit in the table is g.

[0044] Table 2

[0045]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com