A device for separating and burning coarse and fine pulverized coal in a pulverized coal pipeline

A technology of pulverized coal pipeline and fine pulverized coal, which is applied to burners, burners, combustion methods and other directions of burning powder fuel, can solve the problems of low efficiency of coarse powder separators and high content of combustibles in fly ash, and reduce operation and maintenance. cost, compensate for inefficiencies, avoid work environment effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The purpose of the invention of the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, and the embodiments cannot be repeated here one by one, but the implementation of the present invention is not therefore limited to the following embodiments.

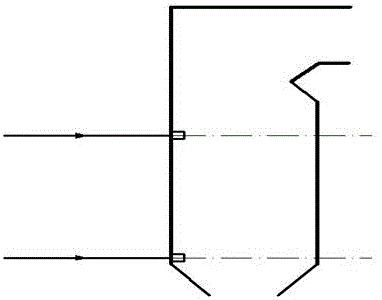

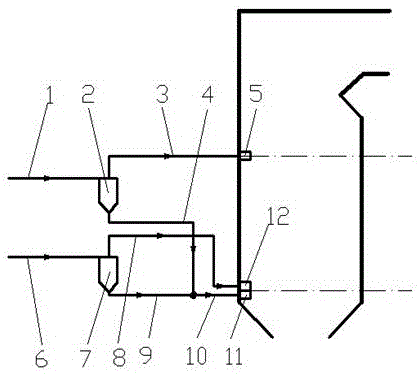

[0023] Below you can refer to the attached figure 1 , figure 2 As well as the text content to understand the innovations of the present invention and the differences between the present invention and the prior art. It should be noted that for the sake of brevity, this document cannot list all the specific embodiments of the present invention, so only a schematic diagram of one embodiment of the present invention is listed in the accompanying drawings. For the use of this invention on the production site, it can be installed between the primary air pulverized coal pipeline and the burner at different heights according to the actual number of laye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com