Tea brick pressing machine and tea brick manufacturing method

A pressing machine and tea brick technology, which is applied in tea processing and sorting before extraction, can solve the problems of high cost, low efficiency, and inability to meet the production needs of enterprises, and achieve the effect of ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings.

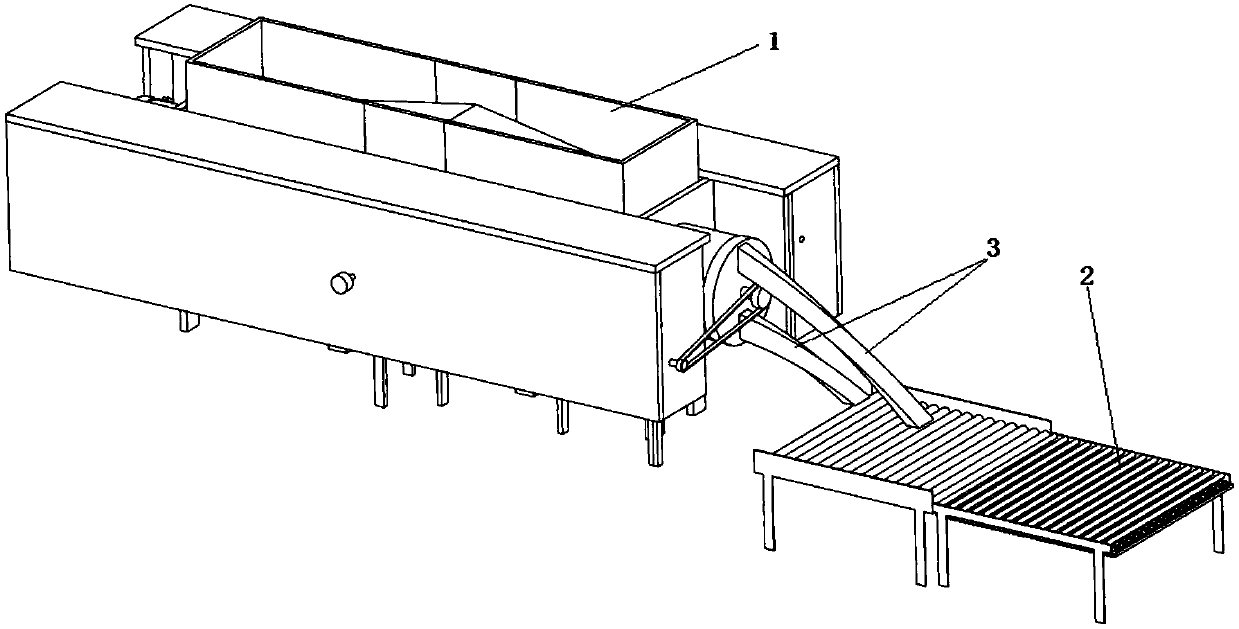

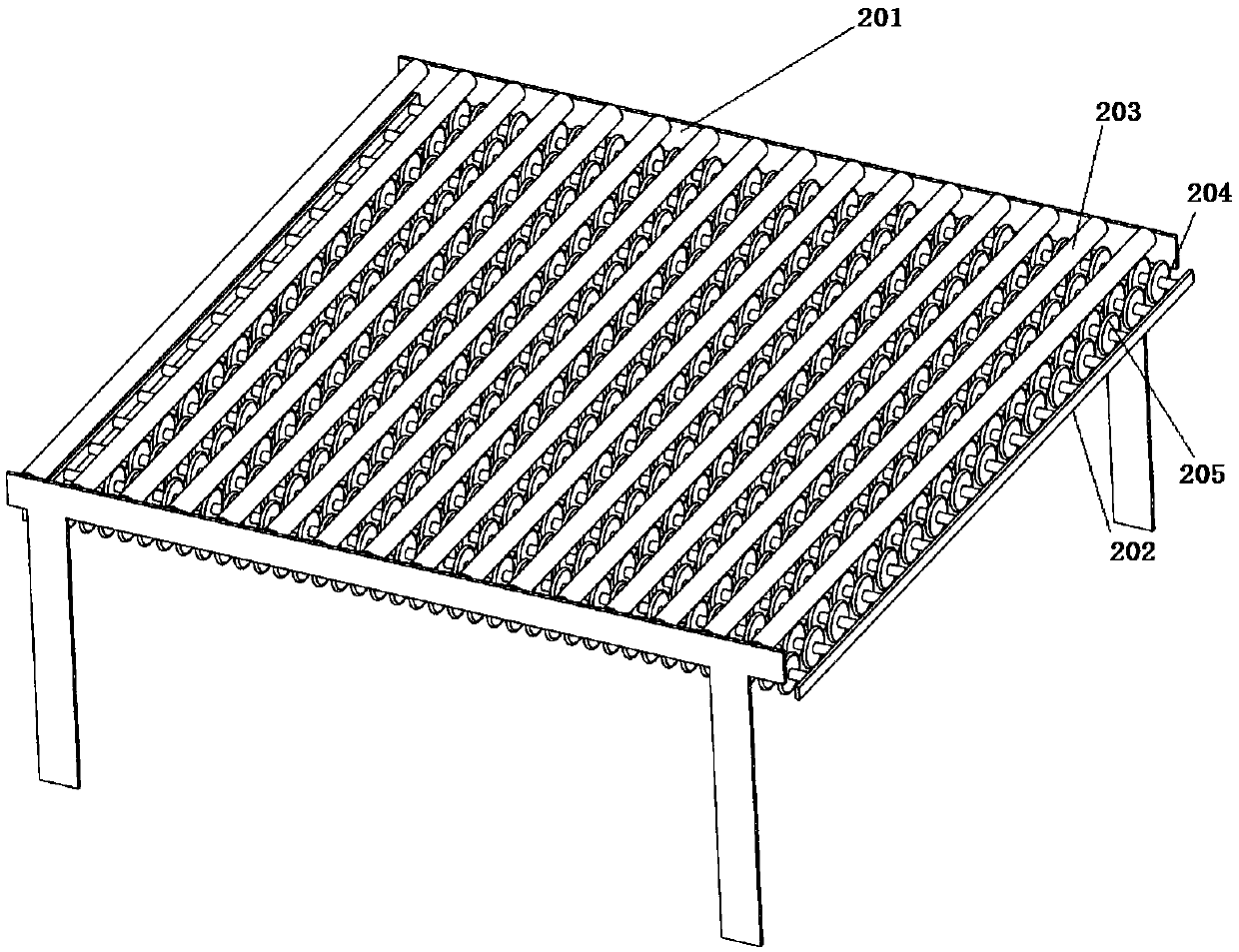

[0037] as attached Figures 1 to 10 The tea brick pressing machine includes a tea brick pressing device 1 and a detection and sorting device 2, the tea brick pressing device is used to press tea leaves into a tea brick shape, and the detection and sorting device 2 is used to detect the quality of the pressed tea bricks Weight, because the volume of the pressed tea brick is certain, so its weight should be used as an important criterion for testing whether the tea brick is qualified.

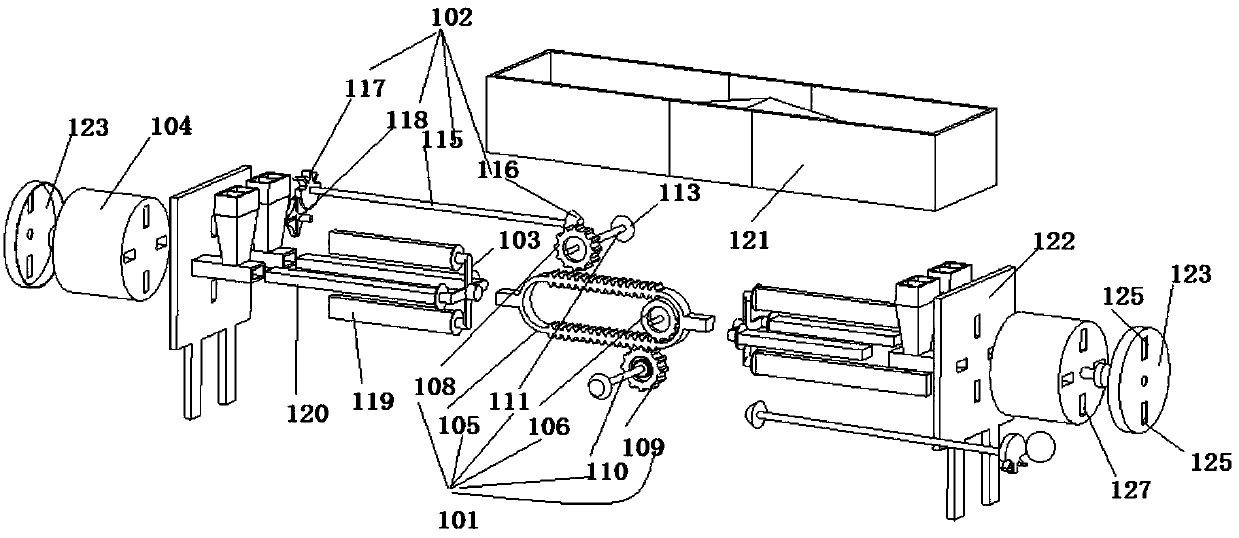

[0038] The tea brick pressing device includes a driving device 101, a transmission device 102, a plurality of push rods 103, a plurality of mold cylinders 104, a first baffle plate 122 and a second baffle plate 123, and the mold cylinder is arranged on the first baffle plate and the second baffle plate. Between the plates, the mold cylinder is respectively connected in rotation with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com