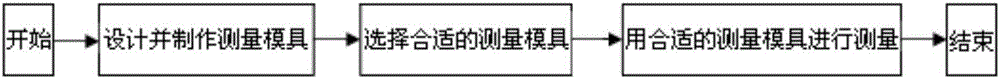

Indirect equivalent measurement method for assembling clearance

A measurement method and gap technology, applied in the direction of mechanical gap measurement, etc., can solve the problems of small space measurement, inaccuracy, and shortened measurement cycle, etc., and achieve the effect of shortened measurement cycle, various methods, and easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with accompanying drawing description and specific embodiment:

[0041] Such as figure 1 As shown, an indirect equivalent measurement method of assembly clearance is used to detect the electrical safety assembly clearance of PCB board. The PCB board includes component body 4, cover plate 5, component lead leg 6, and small cavity casing cover The board 7, the device body 8, the metal beam 9, the device solder joint 10, the fastener 11 and the solder pad 12 include the following steps:

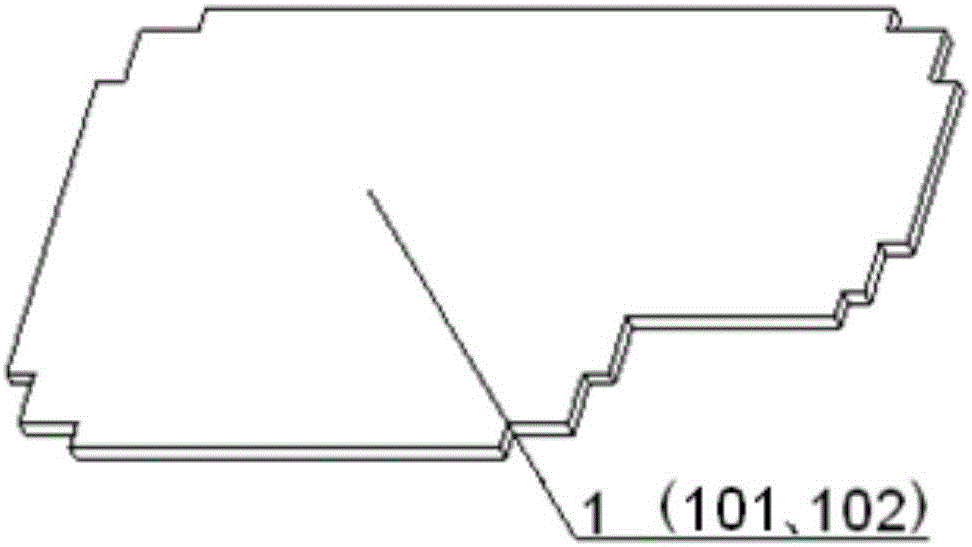

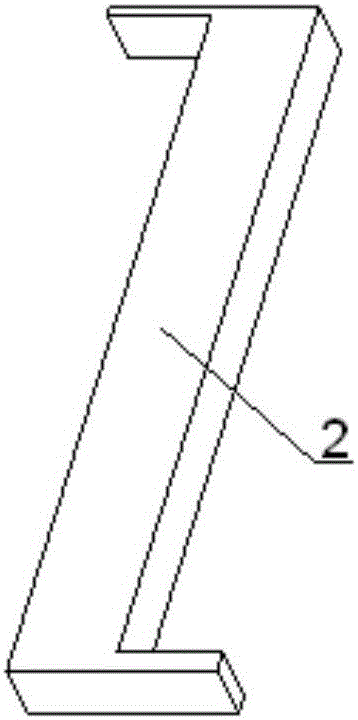

[0042] The first step is to design and manufacture ruler mold 1, folding ruler mold 2 and stick mold 3;

[0043] The second step is to select the ruler mold 1, the folding ruler mold 2 and the rod mold 3 according to the assembly clearance of different parts of the PCB board;

[0044] The third step is to use the selected ruler mold 1, folding rule mold 2 and rod mold 3 to measure the electrical safety assembly clearan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com