speaker module

A speaker module and module technology, which is applied in the direction of speaker transducer fixing, sensor, transducer diaphragm, etc., can solve the problem of reducing the acoustic performance of the speaker module, increasing the F0 of the speaker module, and occupying the space of the rear acoustic cavity, etc. problems, to achieve the effect of increasing work stability and service life, reducing F0, and broadening the frequency band

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

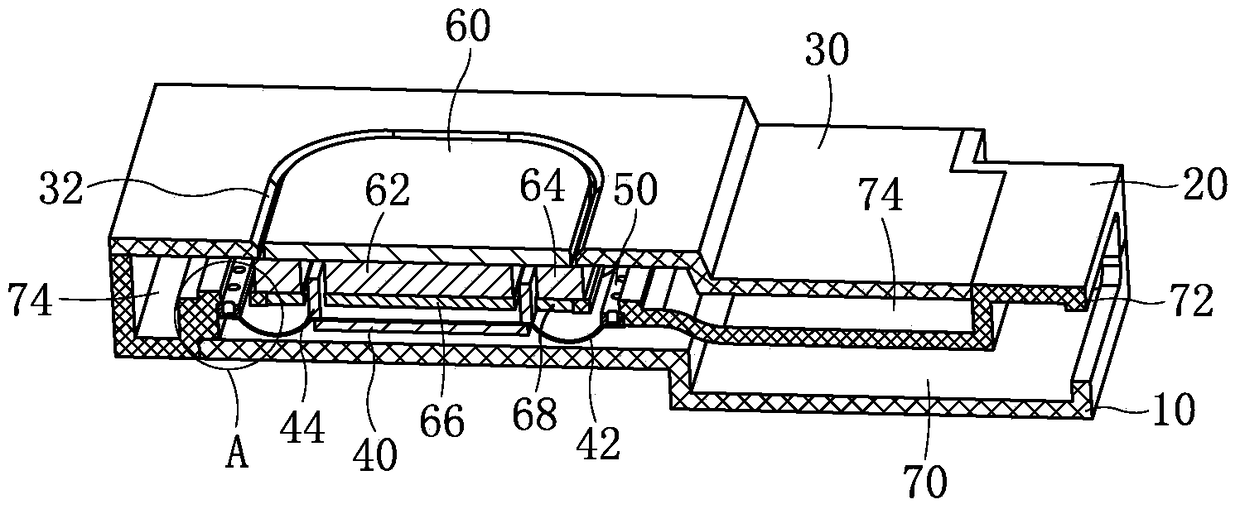

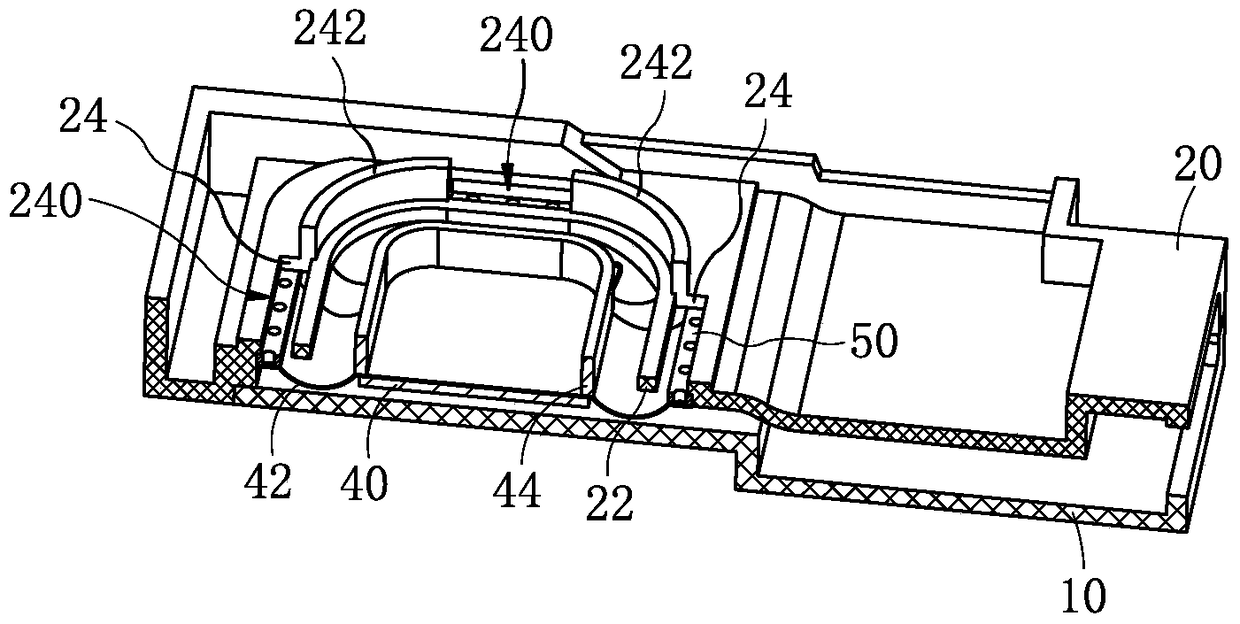

[0032] Such as figure 1 As shown, a loudspeaker module includes a shell, and the shell is composed of an upper shell 10, a middle shell 20, and a lower shell 30 that are sequentially combined, and the space surrounded by the upper shell 10, the middle shell 20, and the lower shell 30 contains Vibration system and magnetic circuit system. The vibration system divides the entire module inner cavity into two cavities, the front acoustic cavity 70 and the rear acoustic cavity 74. The vibration system forms the front acoustic cavity 70 together with the upper shell 10 and the middle shell 20; Together they form a rear acoustic cavity 74. The module is a side sound module, and the sound hole 72 is set at the end of the module away from the vibration system and the magnetic circuit system, and is jointly surrounded by the upper shell 10 and the middle shell 20 .

[0033] Such as figure 1 As shown, the vibration system includes a diaphragm 42 whose edge is fixed on the middle shell...

Embodiment 2

[0041] This embodiment is basically the same as Embodiment 1, the difference is that:

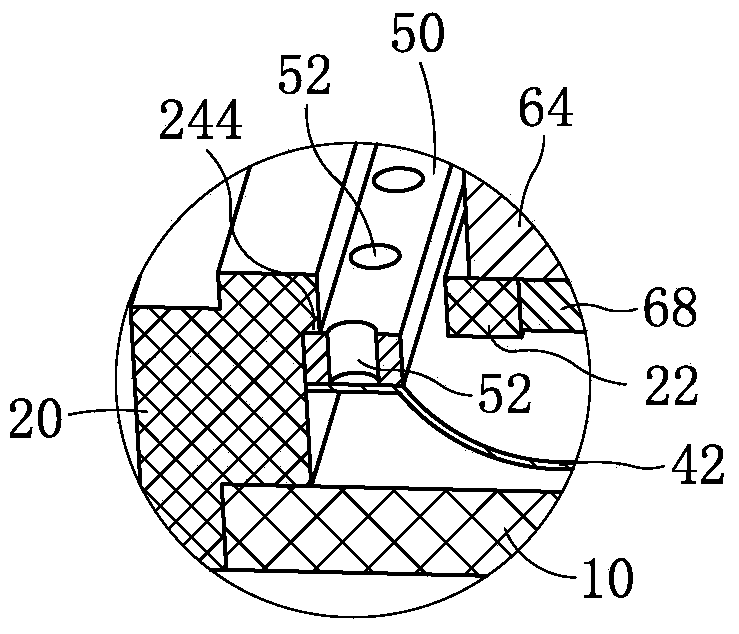

[0042] Such as Figure 5 As shown together, the enlarged cavity portion 52 is disposed on both side edges of the support member 50 , and in practical applications, the enlarged cavity portion 52 may also be disposed only on one side edge portion of the support member 50 .

[0043] The cavity expansion part 52 is arranged on the edge of the support member 50 and can also play the function of expanding the rear acoustic cavity, but compared with the first embodiment, the bonding strength between the support member 50 and the middle shell and the diaphragm of this embodiment is weaker. Therefore, Embodiment 1 is a preferred solution of the present invention.

[0044] The present invention reduces the volume of the support while ensuring the strength of the support by opening holes on the support, increases the effective volume of the rear acoustic cavity, effectively reduces the F0 of the mod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com