speaker module

A loudspeaker module and loudspeaker technology, applied in the direction of sensors, electrical components, etc., can solve the problems of insignificant improvement of the acoustic performance of the speaker module, small contact area between sound-absorbing particles and airflow, and sound-absorbing particles cannot exert sound-absorbing performance, etc., to achieve sound-absorbing The effect is obvious, the sound absorption effect is good, and the effect of F0 is low

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

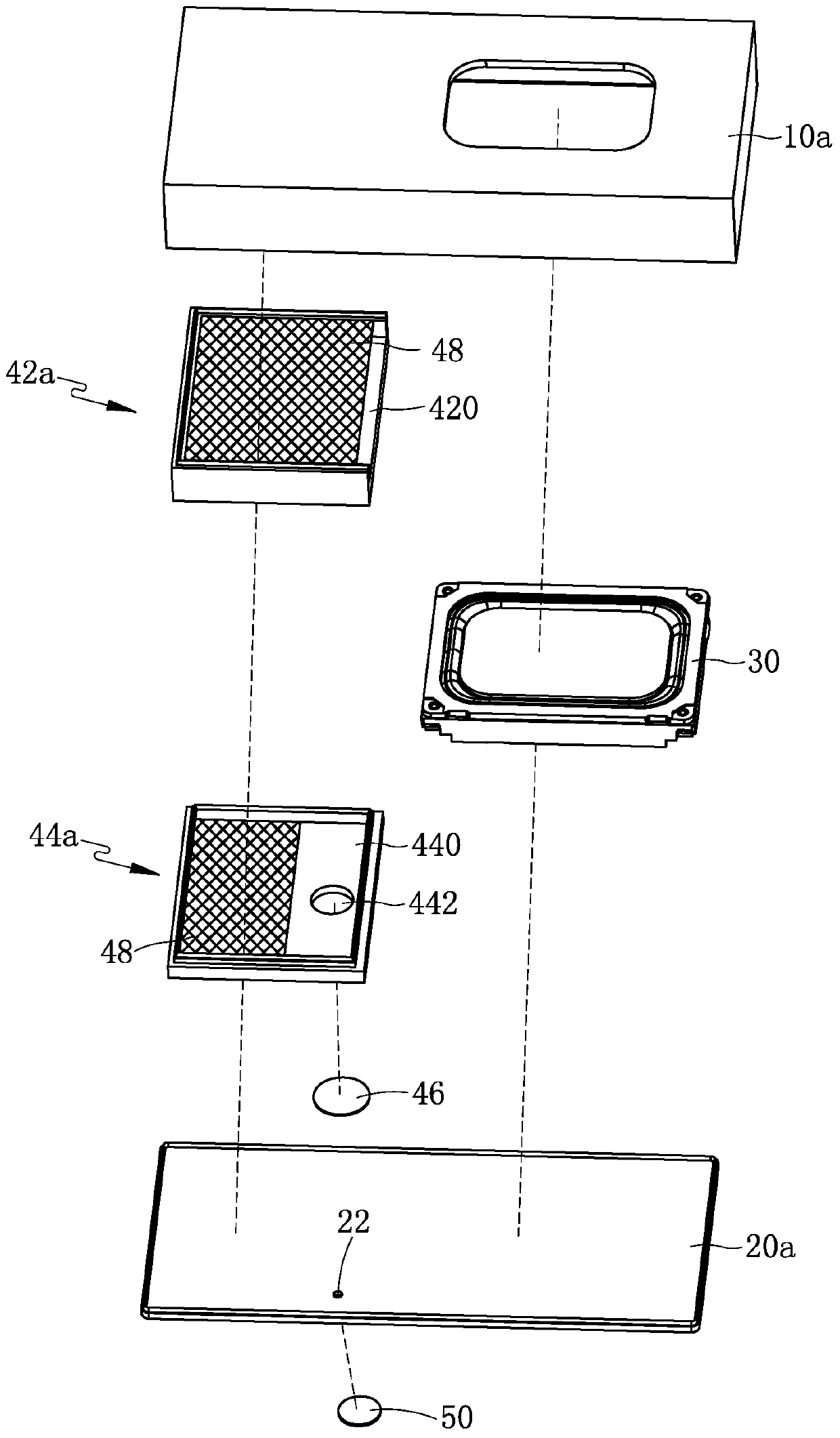

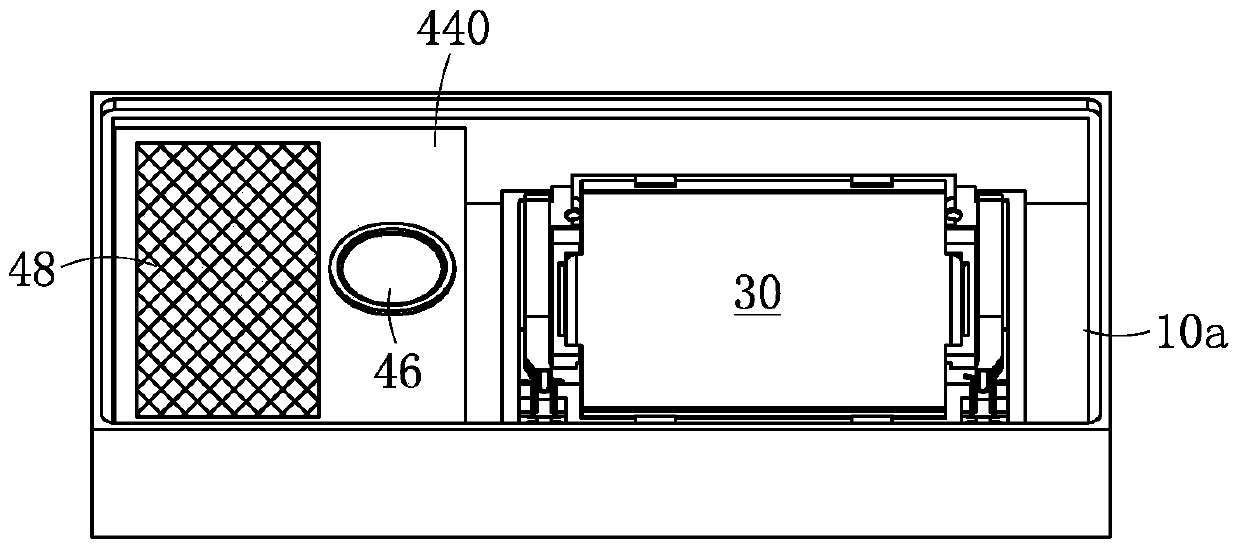

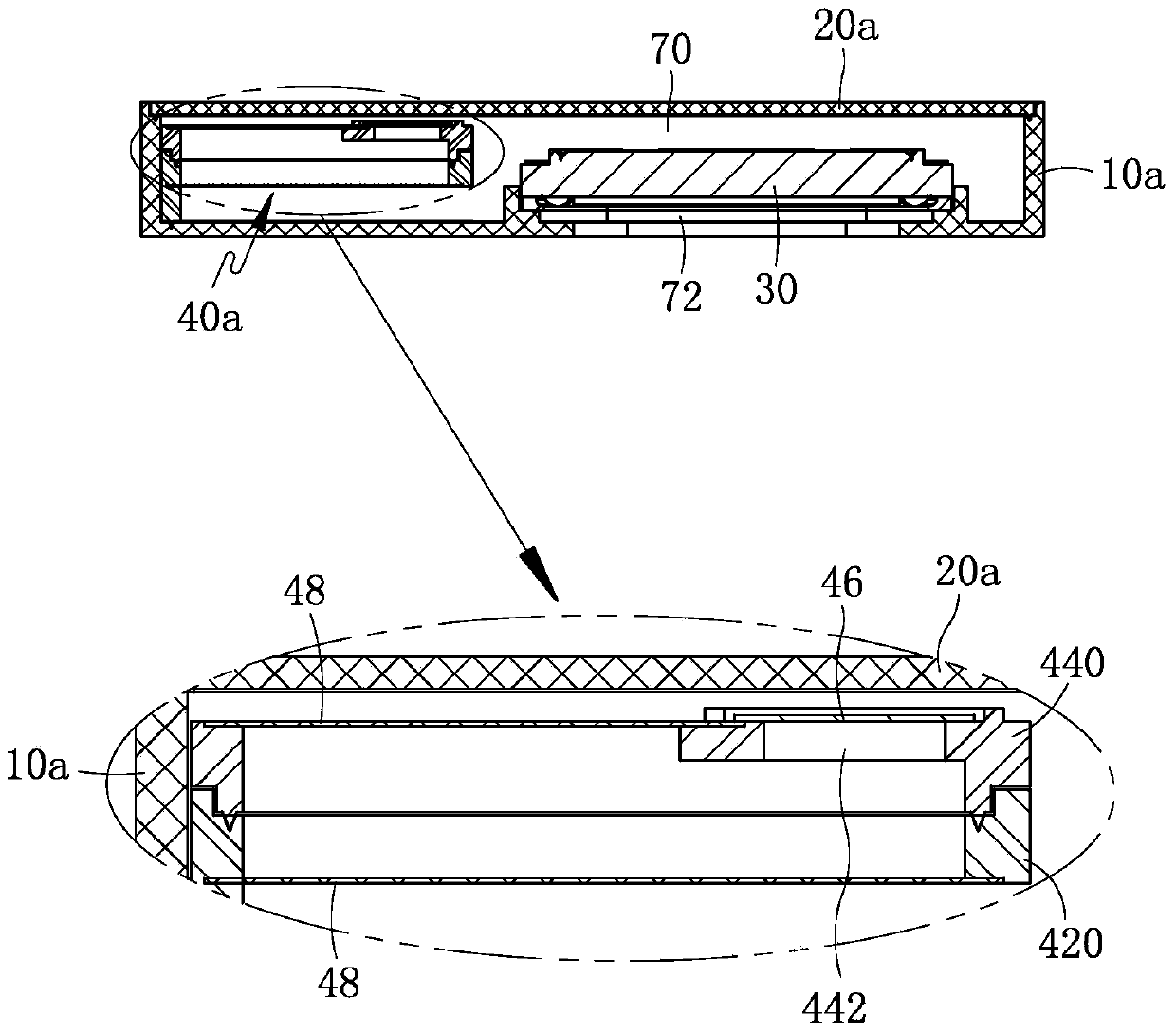

[0029] Such as figure 1 , figure 2 with image 3 Commonly shown, a speaker module includes a module casing, the module casing is composed of a combined first casing 10a and a second casing 20a, and the first casing 10a and the second casing 20a surround A loudspeaker unit 30 is accommodated in the space, and the loudspeaker unit 30 is located at one end of the module. The loudspeaker unit 30 divides the entire module inner cavity into two cavities, the front acoustic cavity 72 and the rear acoustic cavity 70. The loudspeaker unit 30 and the first housing 10a jointly form the front acoustic cavity 72, and the corresponding loudspeaker unit on the first housing 10a The position of the body 30 is provided with a sound hole for sound waves to radiate out; the loudspeaker unit 30 , the first housing 10 a and the second housing 20 a together form a rear acoustic cavity 70 . A sound-absorbing cavity 40a is suspended inside the rear acoustic cavity 70 for filling sound-absorbing m...

Embodiment 2

[0035]This embodiment is basically the same as Embodiment 1, the difference is that:

[0036] Such as Figure 4 , Figure 5 with Image 6 Commonly shown, the module casing includes a first housing 10b and a second housing 20b that are integrated, the speaker unit 30 and the first housing 10b together form a front acoustic cavity 72, the speaker unit 30, the first housing 10b and the second housing 20b together form a rear acoustic cavity 70 . The sound-absorbing cavity 40b located in the rear acoustic cavity 70 is surrounded by the combined sound-absorbing cavity upper shell 42b and the sound-absorbing cavity lower shell 44b. The second housing 20b has an integral structure. That is, the first shell 10b extends inwardly with an upper shell frame 420 , and the second shell 20b extends inwardly with a lower shell frame 440 . Direct injection molding on the middle of the upper shell frame 420 and the lower shell frame 440. In this embodiment, the preferred mesh component is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com