Ulna coracoid process lateral column steel plate

A technology of coronoid process and lateral column, applied in the field of ulna coronoid lateral column plate, to achieve good surgical results, strengthen the stability of fixation, and reduce the scope of dissection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

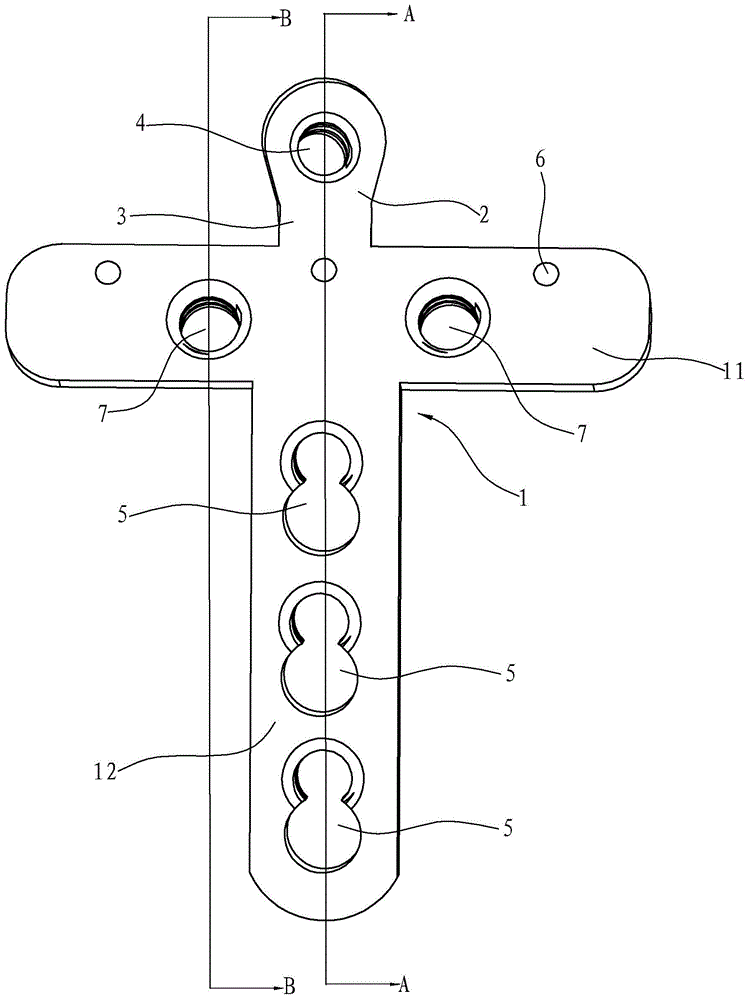

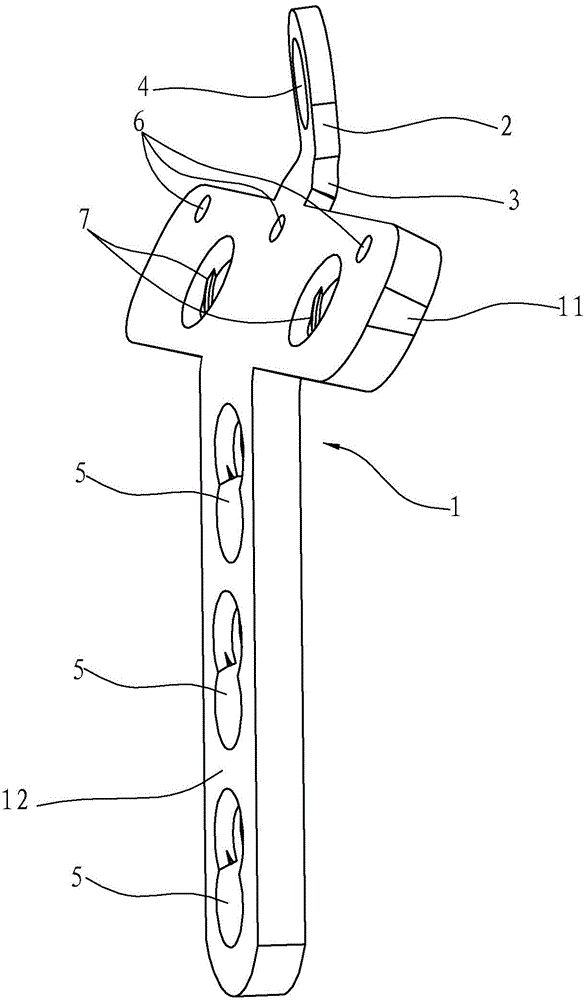

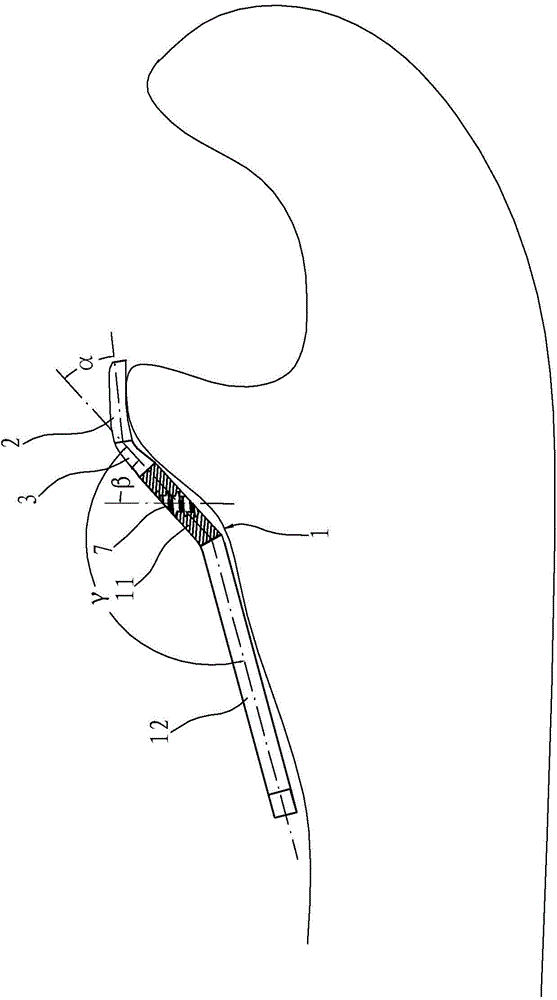

[0022] Such as Figure 1~4 As shown, a steel plate for the lateral column of the ulnar coronoid process includes a head 2 and a plate body 1. The head 2 and the plate body 1 are connected by a helical segment 3, and the helical segment 3 is twisted and transitioned from the plate body 1 to the plate body 2. As a result, the head 2 matches the anatomical shape of the protrusion at the upper end of the lateral column of the ulnar coronoid process, and the helical segment 3 matches the anatomical shape of the transition part between the above-mentioned protrusion and the lower end of the lateral column of the ulnar coronoid process.

[0023] The shape of the plate body 1 can be various. In this embodiment, in order to make the plate body 1 better fix the fracture site, the plate body 1 in this embodiment includes a T-shaped transverse support pla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com