Quick open and close pressure proof watertight hatch cover

A technology of watertight cabins and hatches, which is applied to ship hatches/hatches, ship parts, transportation and packaging, etc., which can solve problems such as failure to meet customer needs, cumbersome opening of hatch covers, low watertight pressure, etc., and achieve structural Simple, reduce property loss, fast and convenient opening and closing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

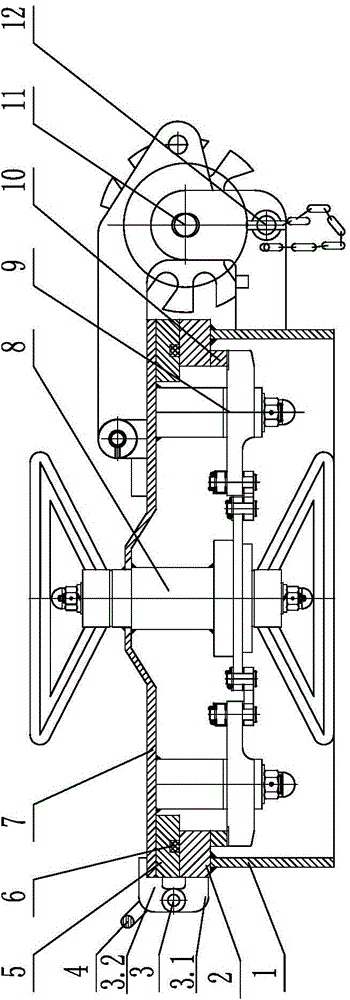

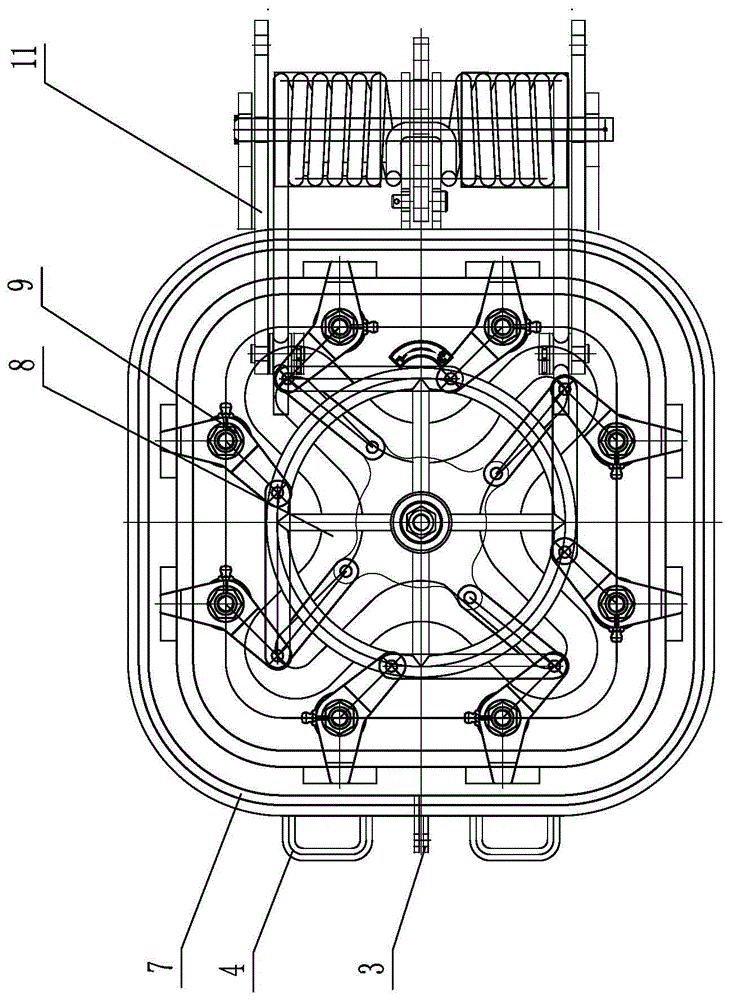

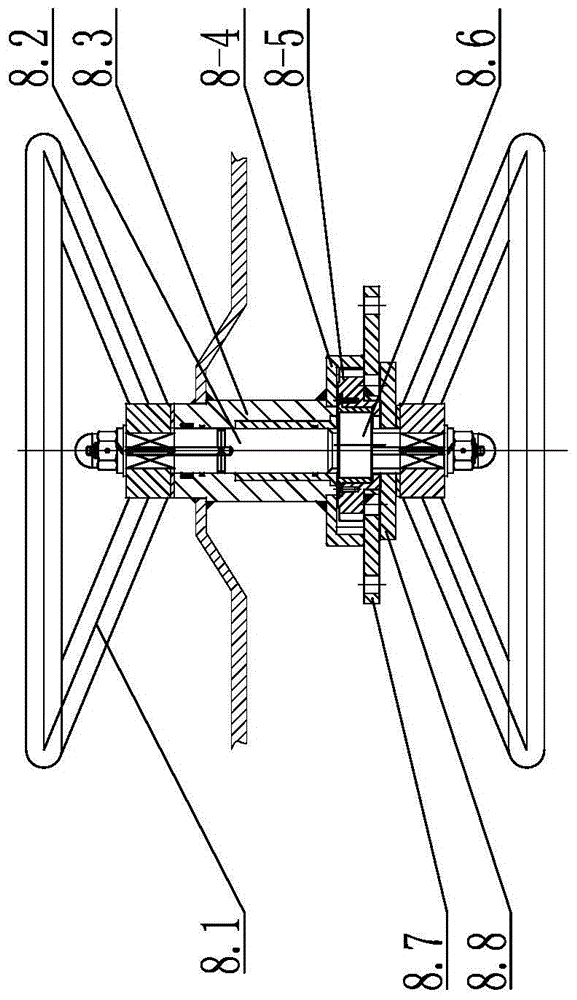

[0021] Such as Figure 1~7 As shown, the present invention mainly includes a coaming plate 1, a lower seat plate 2, a locking device 3, a handle 4, an upper seat plate 5, a watertight rubber strip 6, a cover plate 7, a handwheel transmission mechanism 8, a linkage pressing device 9, an oblique Lease 10 and spring hinge device 11, lower seat plate 2 upper end supports upper seat plate 5, lower seat plate 2 lower end welding coaming plate 1, upper seat plate 5 upper end welding cover plate 7. The upper seat plate 5 is provided with a circle of watertight sealing strip groove along the circumferential direction, and a watertight rubber strip 6 is arranged in the watertight sealing strip groove, and the contact end surface of the upper seat plate 5 and the lower seat plate 2 is sealed by the watertight rubber strip 6 .

[0022] One side of the lower seat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com