An anti-dumping support for vertical electrodialysis equipment

An electrodialysis and anti-dumping technology, applied in the directions of dispersed particle separation and separation methods, etc., can solve the problems of vertical electrodialysis equipment toppling, unstable center of gravity, injury accidents, etc. Accident, the effect of guaranteeing the safety of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

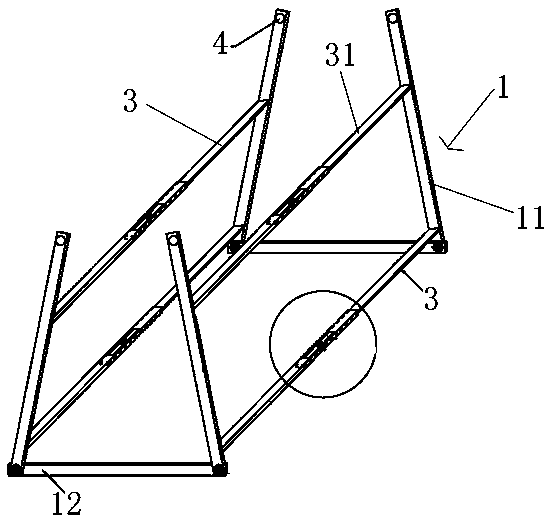

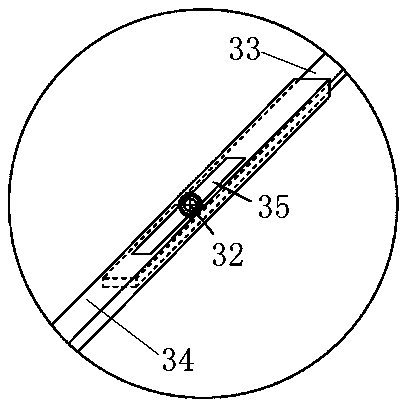

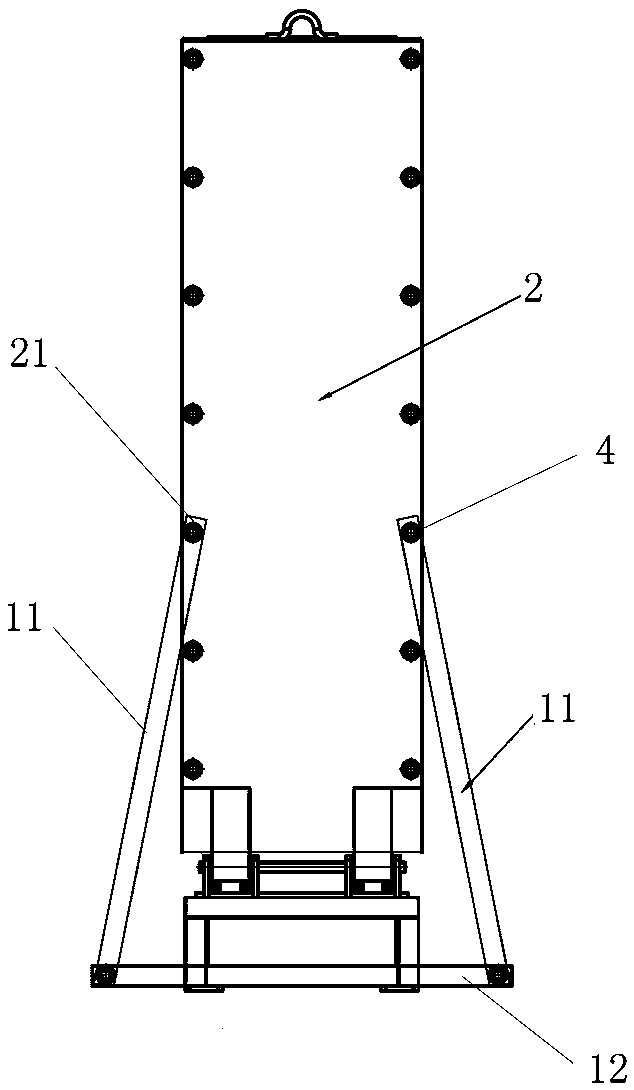

[0015] The 400mm*1600mm vertical electrodialysis anti-dumping support of the present invention mainly consists of several aluminum alloy rods, these aluminum alloy rods are called support rods 11, bottom connecting rods 12, and transverse connecting rods 3 respectively according to their functions; The support rod 11 is connected with the bottom connecting rod 12 by bolts, which is convenient for dismounting. The supporting rod 11 and the transverse connecting rod 3 are all connected by welding. Transverse connecting rod 3 is formed by connecting poles 31 made of aluminum alloy square tubes with different specifications. Two butted poles have a waist hole 35 at one end.

[0016] The purpose of the present invention is to reduce the risk of dumping of the 400mm*1600mm vertical electrodialysis equipment, and improve the operational safety factor during the operation and transfer of the equipment. In the actual process of using a forklift for transfer, as long as the steel fork ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com