Revolved support assembly and engineering machine therewith

A slewing support and component technology, applied in cranes and other directions, can solve the problems of difficult hole alignment of the slewing support, and achieve the effect of solving the difficulty of hole alignment and rapid positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

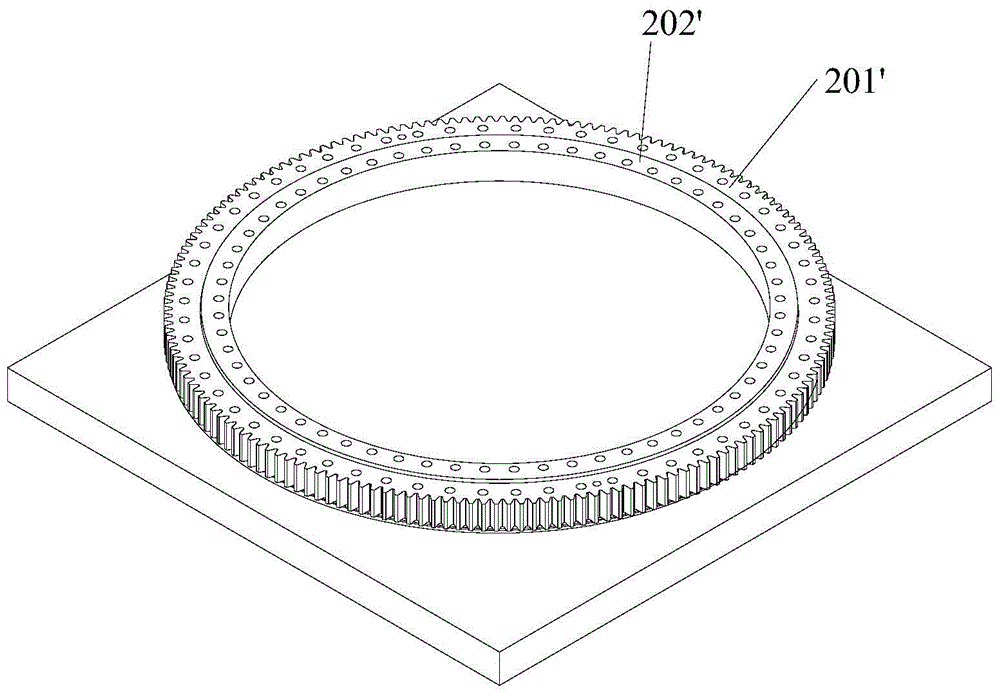

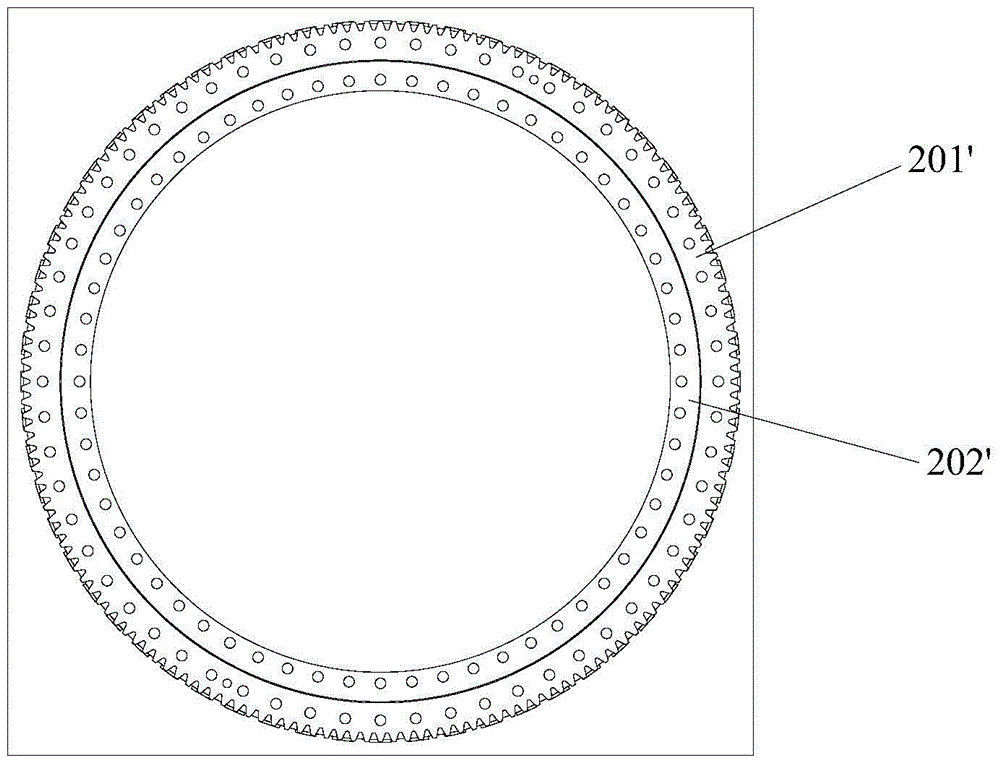

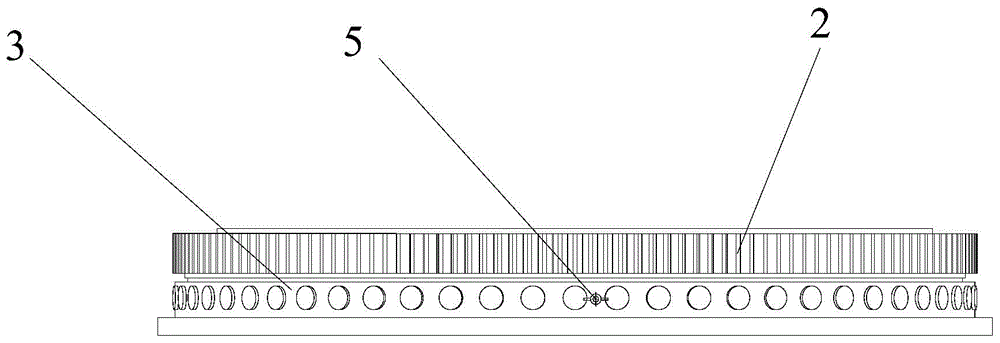

[0032] Such as image 3 with Figure 4 As shown, the slewing support assembly of this embodiment includes: a slewing support 2 , a mounting sleeve 3 and a fastening assembly. Among the above components, the slewing support 2 includes an outer ring 201 and an inner ring 202 that are relatively rotatable. The installation sleeve 3 is fixedly arranged on the vehicle frame, and a plurality of matching holes are arranged on the circumferential side wall of the installation sleeve 3 . The outer ring 201 of the rotary support 2 is provided with a plurality of installation holes 203 corresponding to the positions of the plurality of matching holes. Wherein, a positioning structure is provided betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com