Folding lithium ion battery polar group and its producing method

A lithium-ion battery, foldable technology, applied in the field of lithium-ion batteries, can solve the problem of difficult control of pole piece alignment, achieve the effect of solving the difficulty of pole piece alignment, improving utilization rate, and reducing design difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

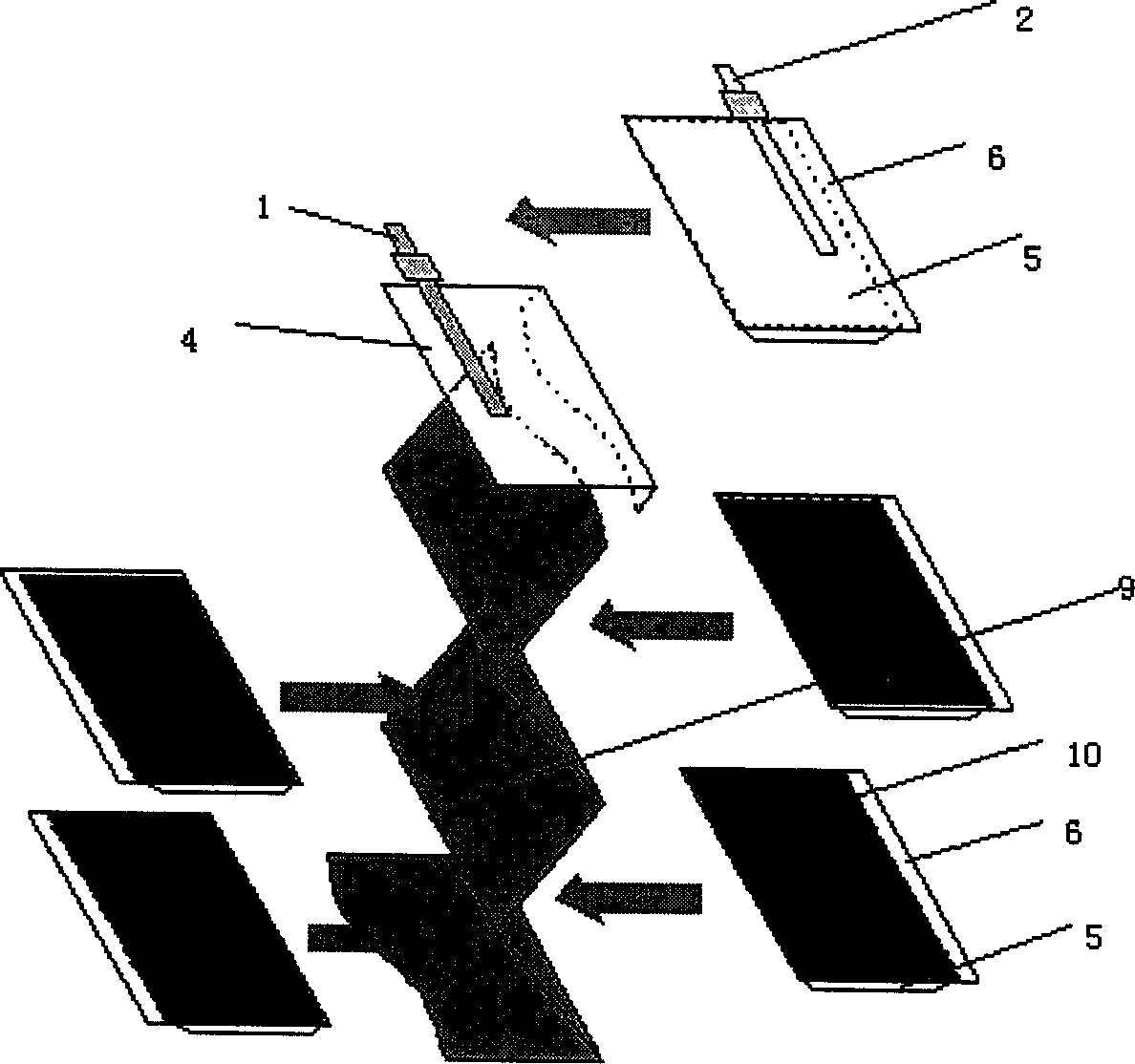

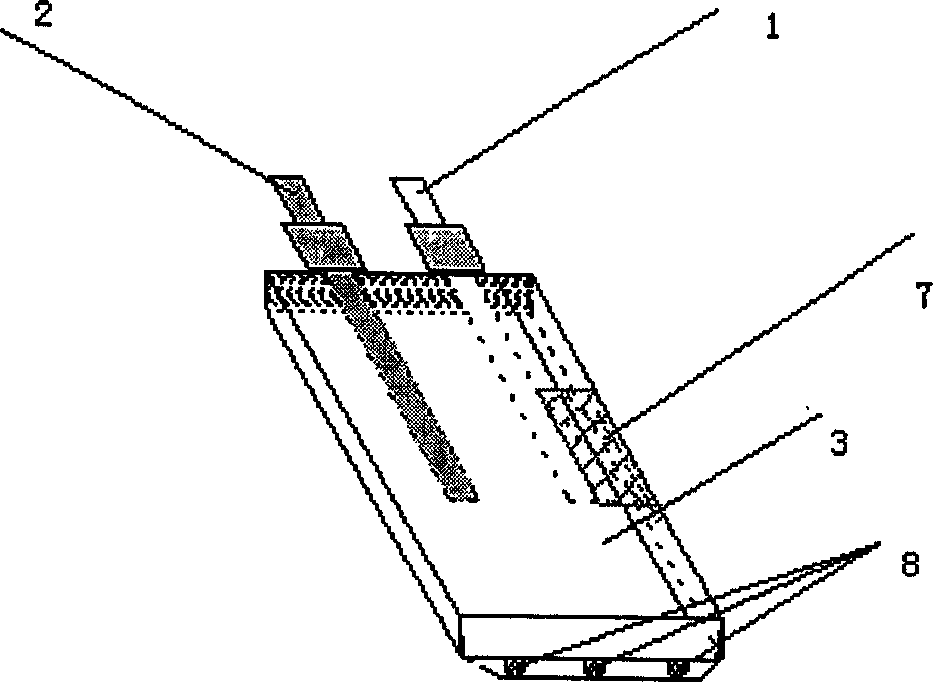

[0031] The present invention will be further described in detail according to the accompanying drawings and embodiments.

[0032] The electrode of the lithium-ion battery is much larger than the positive electrode LiCoO due to the specific capacity of the negative electrode graphite 2 Therefore, it is the positive electrode sheet that enhances the uncoilability of the electrode under a high coating amount, and the winding of the negative electrode sheet is no problem. Therefore, the first consideration of the present invention is to stack the positive electrode sheet, and the negative electrode sheet does not Changed pole group production mode. However, it is not feasible to wind the negative electrode sheet, because the size of the positive electrode will be uneven, and there will be many difficulties in the manufacture of such a positive electrode sheet, although this will solve the positioning problem of the positive electrode sheet. Therefore, the negative electrode sheet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com