Automotive crash test dummy hip joint calibration device

A collision test and hip joint technology, which is applied in vehicle testing, impact testing, machine/structural component testing, etc., can solve the problem that the rocker arm cannot be replaced, the rocker arm extends into the dummy hip joint position adjustment is inconvenient, and has universality No problem, etc., to achieve the effect of protecting the force rod

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing of description:

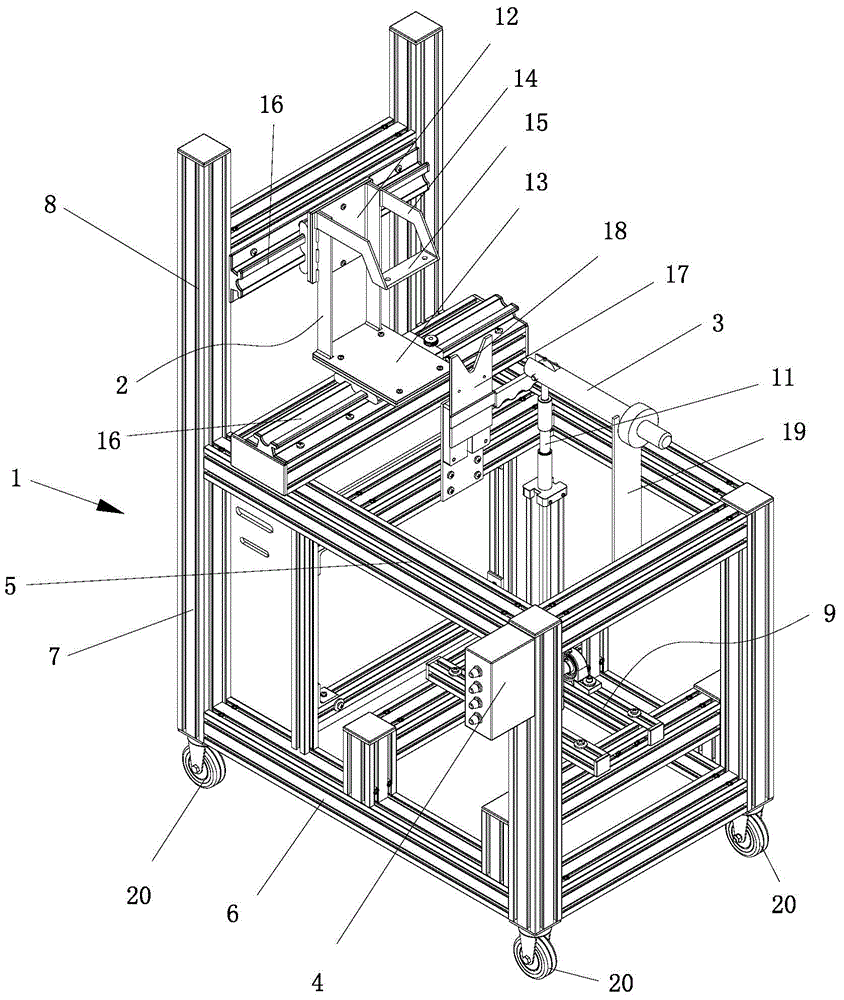

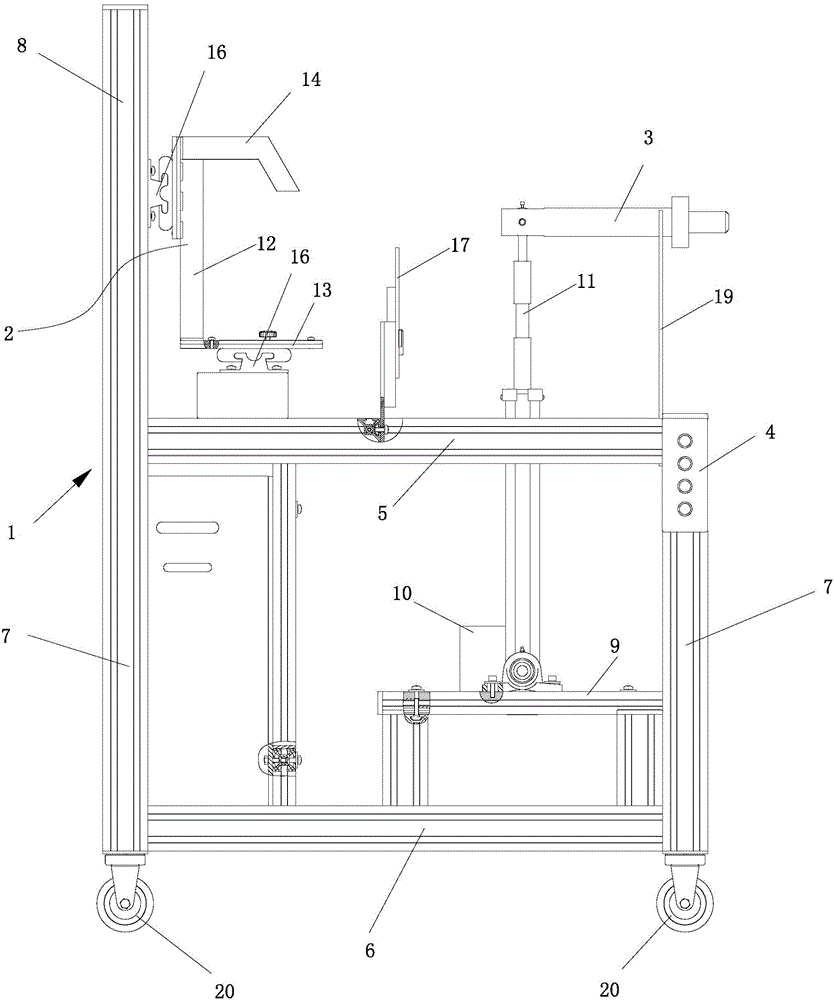

[0024] as attached Figure 1~2 As shown, a car crash test dummy hip joint calibration equipment includes a stand 1, a hip joint fixture 2 slidingly arranged on the stand 1 for fixing the dummy hip joint, and a hip joint with one end extending into the dummy hip joint. The thigh hole and the force application rod 3 fixedly connected with the dummy hip joint, the lifting mechanism connected to the other end of the force application rod 3 for applying a lifting force to the force application rod 3, and the lifting mechanism electrically connected to the lifting mechanism for control The control system 4 of the lifting mechanism, the control system includes a stroke control switch for controlling the lifting mechanism to apply force to the force applying rod 3, so that when the angle between the force applying rod 3 and the horizontal plane exceeds a certain angl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com