parathyroid homogenizer

A technology for homogenizing and crushing parathyroid glands, which is applied in the field of medical devices, can solve the problems of time-consuming and laborious, and the parathyroid glands are small in size and not easy to be fully crushed, etc., and achieve the effect of convenient operation and simplified structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

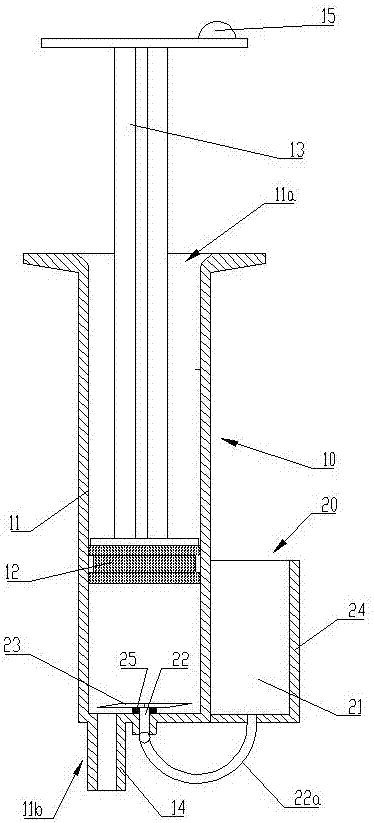

[0015] The present invention will be described in detail below in conjunction with accompanying drawing:

[0016] Such as figure 1 As shown, the parathyroid homogenate breaker in this embodiment includes a syringe 10 and a breaker 20, the syringe 10 includes a syringe 11 and a push rod 13 with a rubber stopper 12 at the front end, the syringe 11 One end is an open end 11a, and the other end is an injection end 11b provided with a drain tube 14 connected to an injection needle. The rubber stopper 12 is set to be inserted into the syringe from the open end of the syringe 11 and It is in a sealing sliding fit with the syringe 11 in the axial direction, and an injection chamber is formed between the inner end surface of the rubber stopper 12 and the inner wall of the syringe 11, and one end of the push rod 13 extends into the syringe 11 and The rubber stopper 12 is fixedly connected; the breaker 20 includes a motor 21 and a stirring shaft 22 connected to the motor 21 and a blade ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| weight | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com