A gamma ray detection device

A detection device, gamma ray technology, applied in the direction of using radiation for material analysis, etc., can solve problems such as small safety range, and achieve the effect of saving manpower, ensuring safety, and tight construction schedule

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing and specific embodiment, the present invention will be further described:

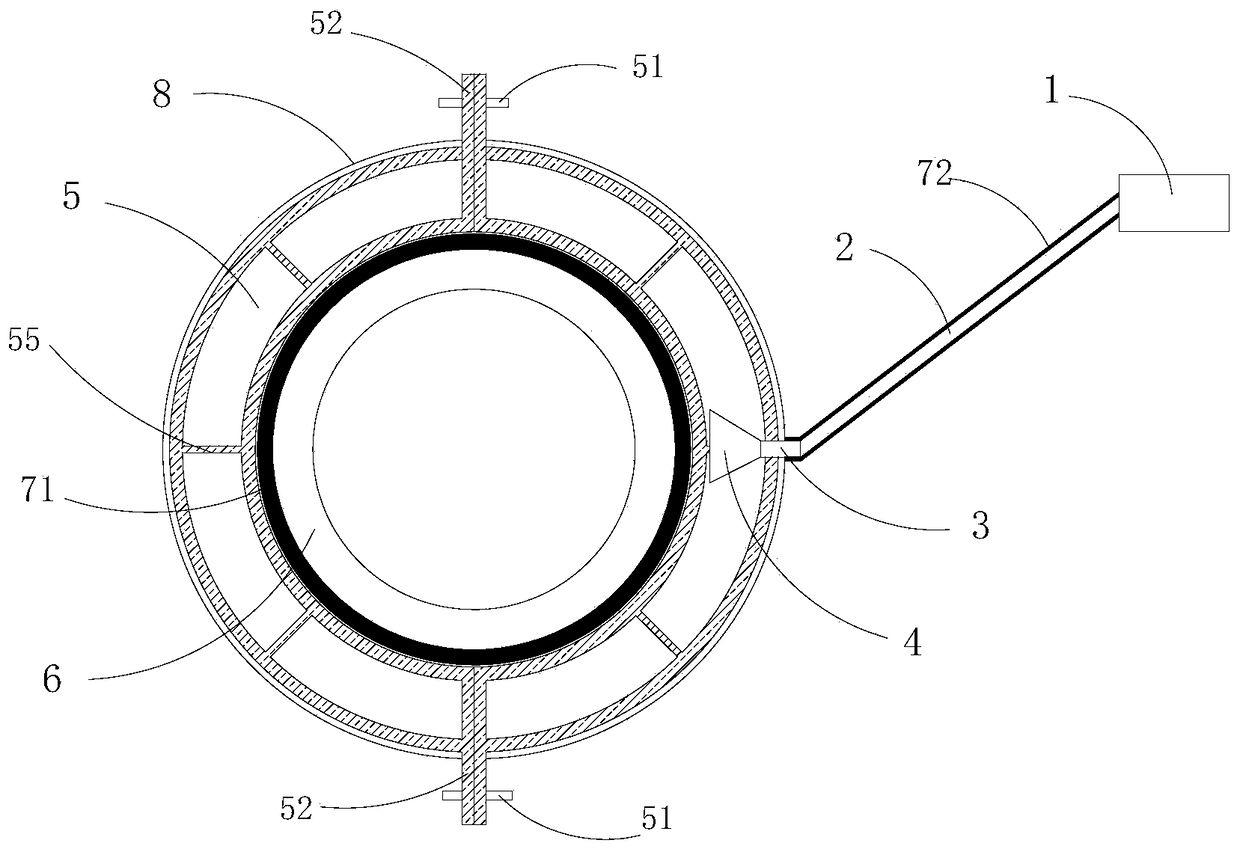

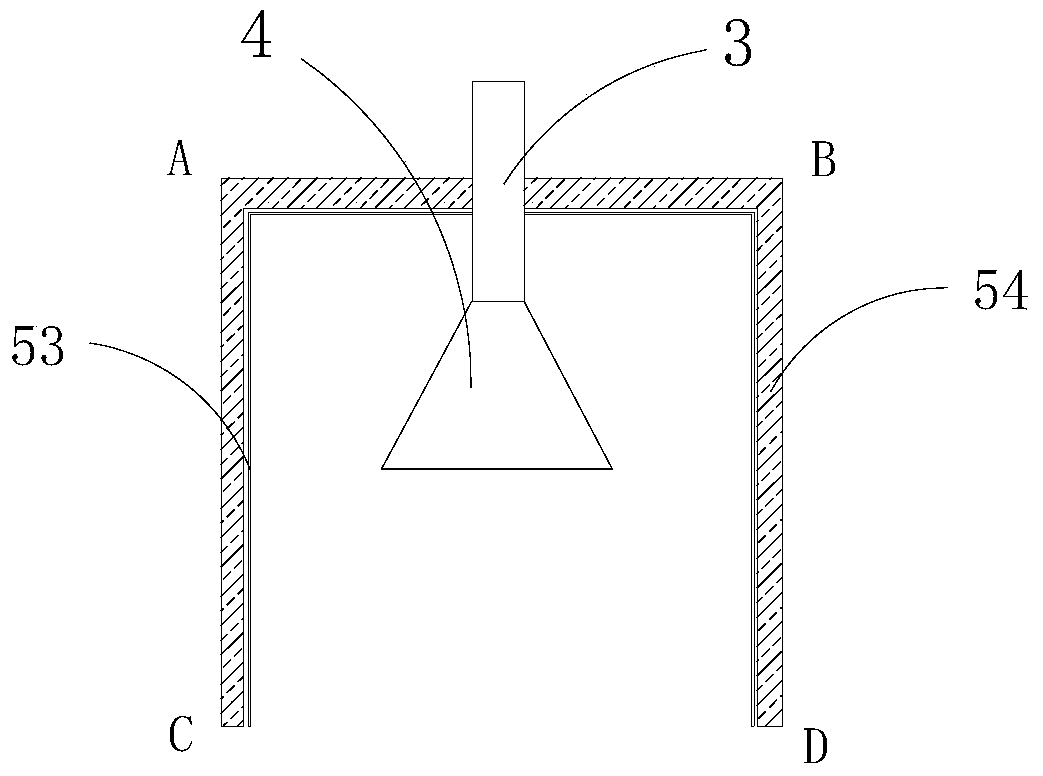

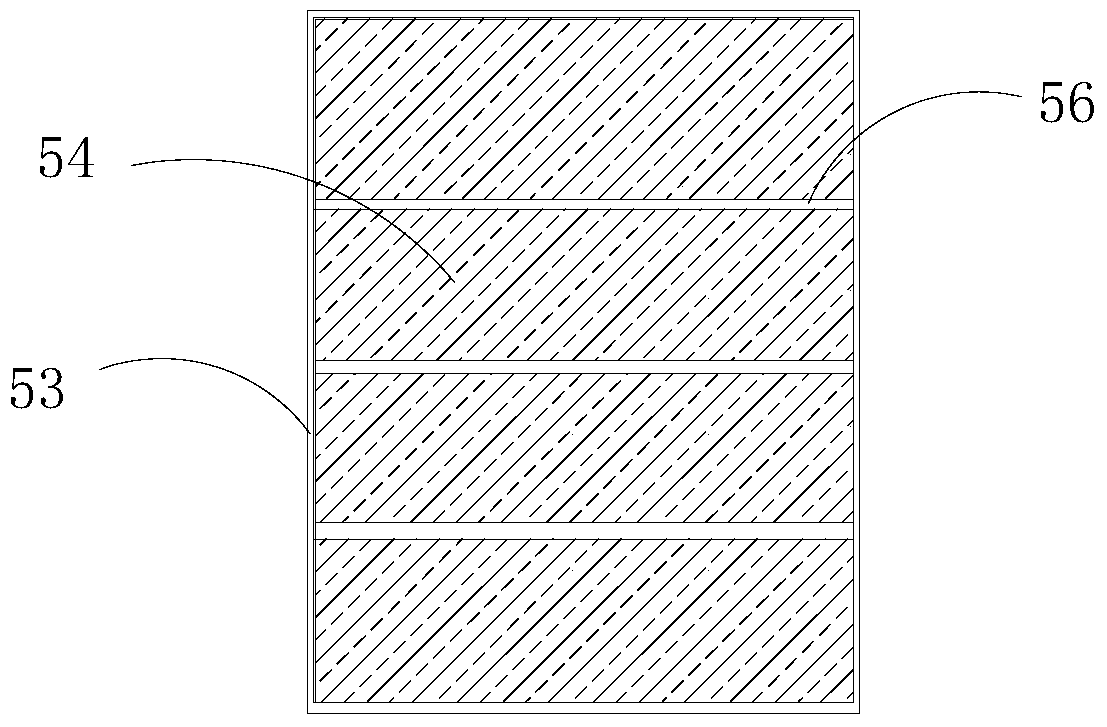

[0025] See figure 1 , figure 2 as well as image 3 , the present invention relates to a gamma-ray detection device, and its preferred embodiment includes a gamma-ray flaw detector 1, a source tube 2, a focus adjustment tube 3, a directional exposure head 4, and a lead plate shielding ring 5; one end of the source tube 2 Connected with gamma ray flaw detector 1, the other end of the source tube 2 is connected with the directional exposure head 4 through the focus adjustment tube 3; the focus adjustment tube 3 is screwed on the lead plate shielding ring 5, and the directional exposure head 4 is located The inside of the ring 5 is used to irradiate the flaw detection position of the pipeline to be tested 6; The first lead rubber 71 on both sides of the position to be detected of the pipeline 6 ; the outside of the source pipe 2 and the outside of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com