Production line for drying casing

A production line and casing technology, which is applied in the processing of animal intestines, etc., can solve the problems of difficulty in flat laying, slow processing, and affecting the efficiency of production and processing, so as to reduce the drying time, ensure the effect and quality, and reduce the contact area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

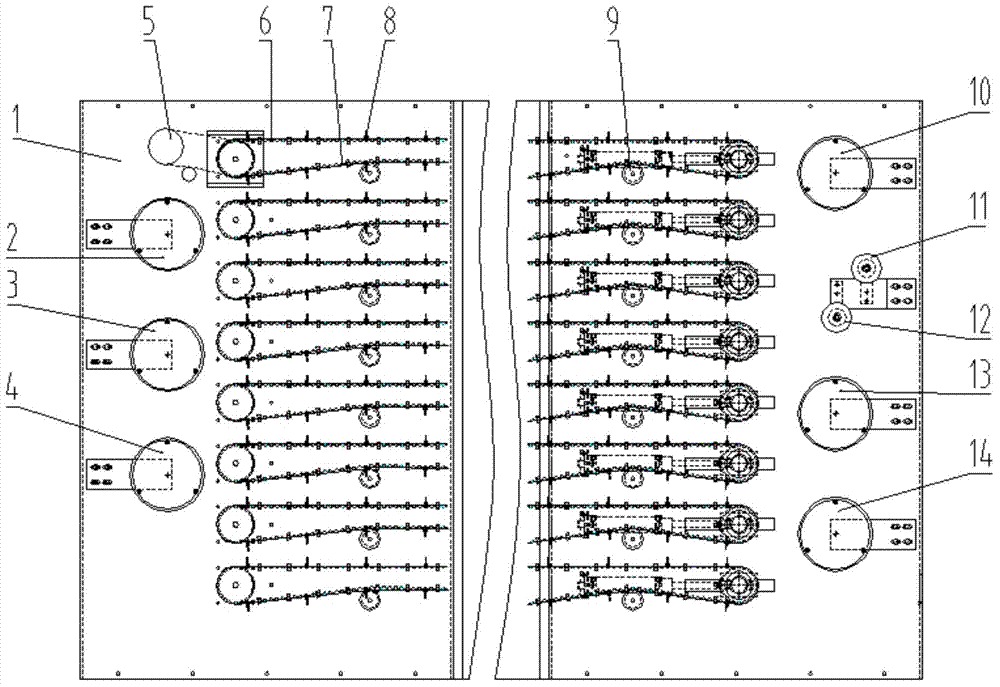

[0022] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

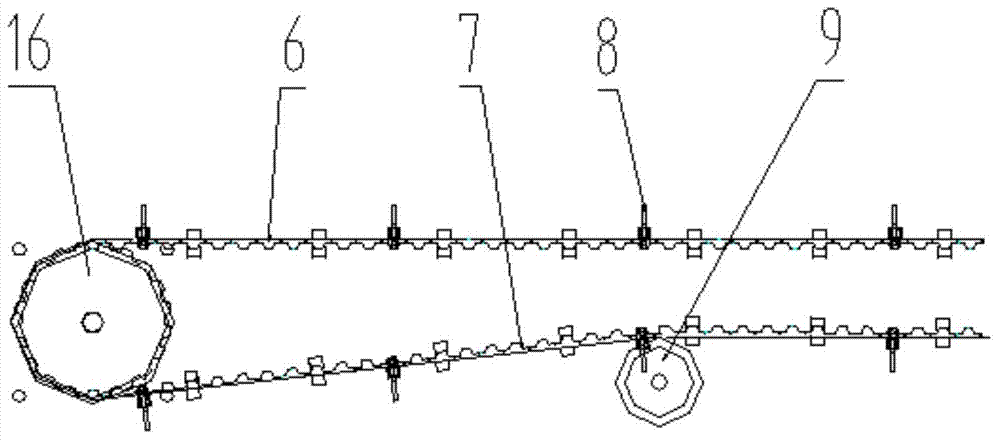

[0023] like Figure 1-Figure 5 As shown, the present invention provides a casing drying production line, which includes a frame on which multiple sets of casing support frames and drying frames 15 are arranged. The frame includes a base plate and a side plate 1, the side plate 1 is vertically fixed on the base plate, and the casing supporting frame and the drying rack 15 are fixed on the side plate 1. Wherein the casing supporting rack and the drying rack 15 are arranged alternately from top to bottom.

[0024] A number of casing support bars 8 are arranged on the casing support frame, and the casing support bars 8 are evenly distributed at equal intervals along the length direction of the casing support frame. Each casing support bar 8 is provided with four grooves, and the grooves have upward openings , in a semicircular arc shape, the gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com