Three-level energy dissipation unit and energy dissipation guardrail device

An energy dissipation and damage technology, which is applied to road safety devices, roads, roads, etc., can solve the problems of poor energy dissipation effect of anti-collision guardrails, and achieve the effect of solving large space occupation, good effect and increasing friction effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

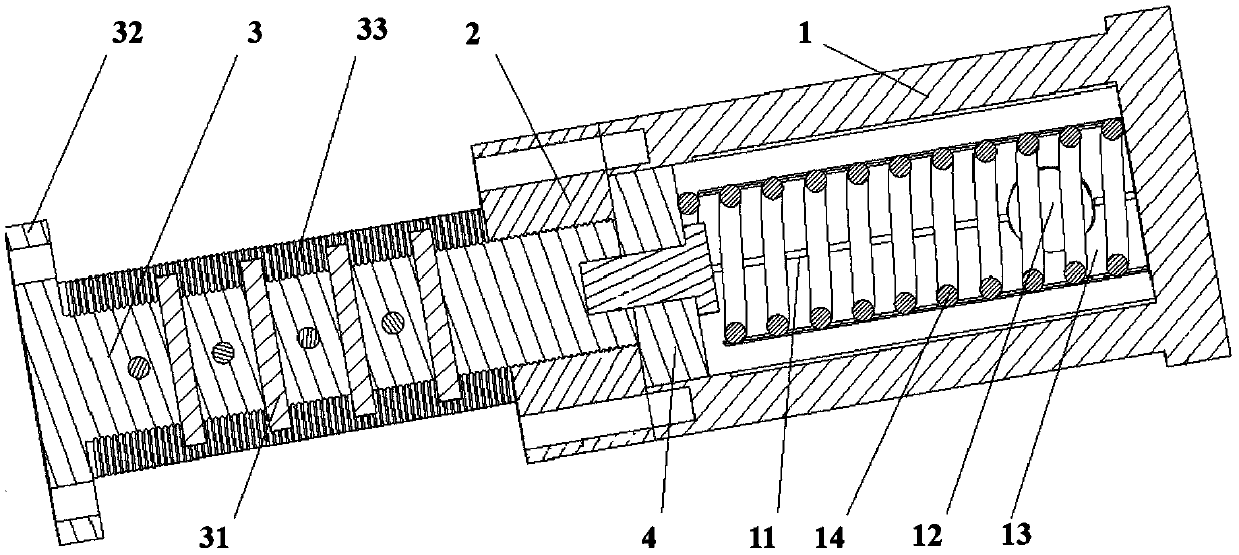

[0038] Such as Figures 1 to 7 As shown, a three-stage energy dissipation unit includes an energy dissipation sleeve 1, a damaged body sleeve 2, and a damaged body shaft 3 connected coaxially in sequence; one end of the energy dissipation sleeve 1 is closed, the other end is open, and the open end Connect the damage body sleeve 2, the inner wall of the energy dissipation sleeve 1 is provided with multiple water guide grooves 11, the side wall of the energy dissipation sleeve 1 is provided with water flow holes 12; the inner wall of the damage body sleeve 2 and the outer wall of the damage body shaft 3 It is a corrugated friction surface and is in close contact; one end of the damaged body shaft 3 extending into the damaged body sleeve 2 is connected with a sealing block 4, and the sealing block 4 and the inner wall of the energy dissipation sleeve 1 form a sealed cavity 13, and the sealing block 4 and the inner wall of the energy dissipation sleeve 1 form a sealed cavity 13. A...

Embodiment 2

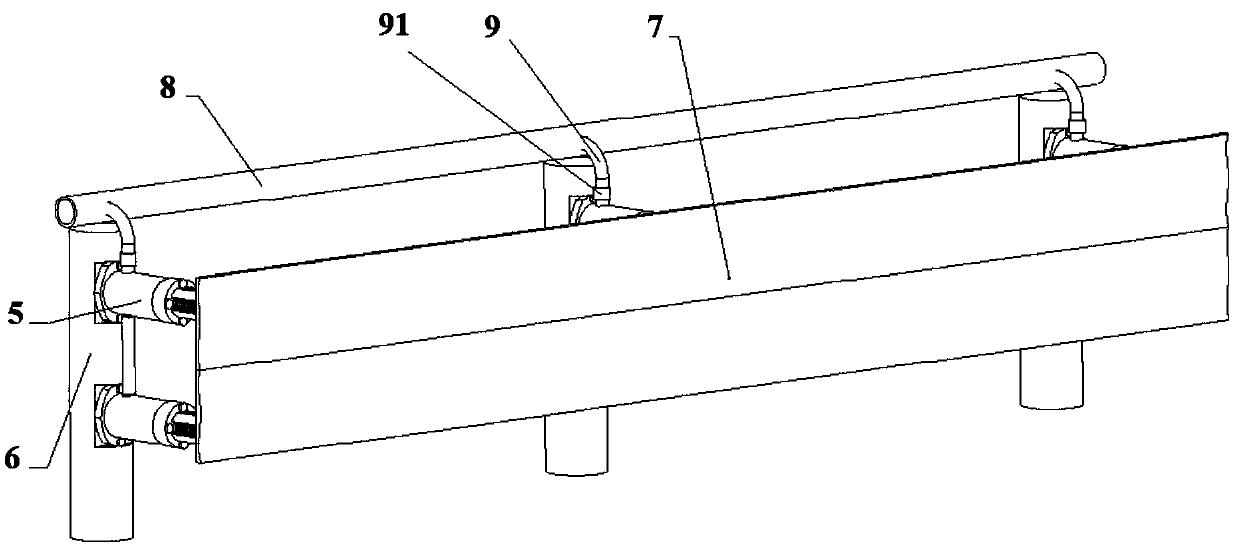

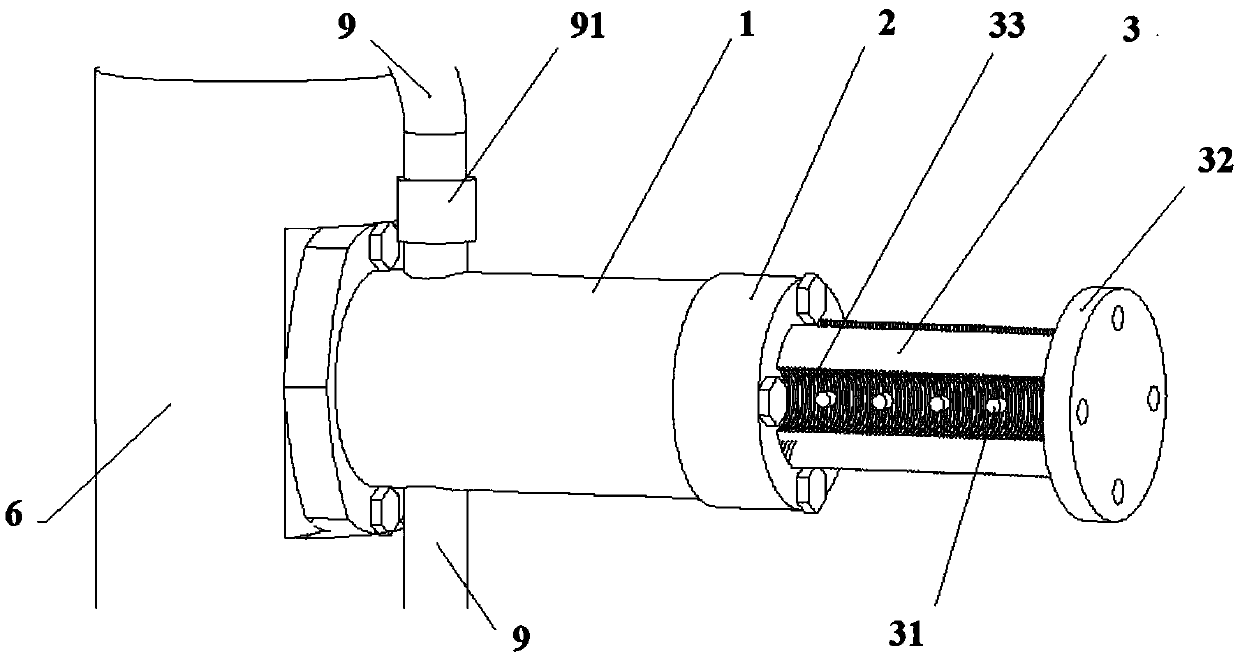

[0047] Such as figure 1 As shown, this embodiment provides an energy-dissipating guardrail device, which includes multiple three-stage energy-dissipating units 5 in Embodiment 1, and also includes multiple fixed shafts 6 and vertical collision baffles 7 parallel to the fixed shafts 6 And the water supply pipe 8; the sealing end of the energy dissipation sleeve 1 is installed on the fixed shaft 6, the baffle connecting flange 32 is installed on the collision baffle 7, and the energy dissipation sleeve 1 and the damaged body axis 3 are perpendicular to the fixed shaft 6 and the collision baffle 7; the water flow hole 12 and the water supply pipe 8 are in sealed communication through the hose 9, and the hose 9 is provided with a one-way valve 91. Among them, the fixed shaft 6 is vertically fixed on the ground; this embodiment adopts the buffer energy dissipation method of water to make the collision process smooth, specifically, the water energy is replenished into the sealed cav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com