Controllable variable spray gun

A spray gun and variable technology, applied in the direction of spraying devices, liquid spraying devices, etc., can solve the problems of leaky irrigation at corners, low land utilization rate, and inability to irrigate, and achieve the effects of improving utilization rate, saving manpower and material resources, and reducing material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

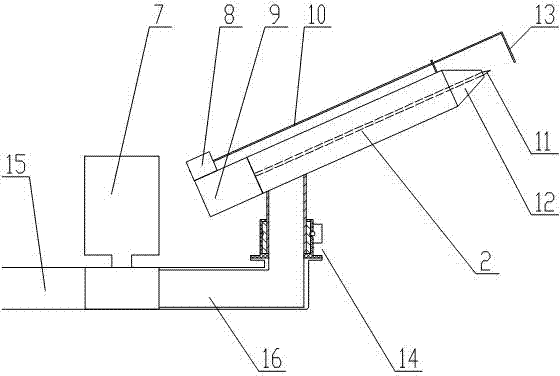

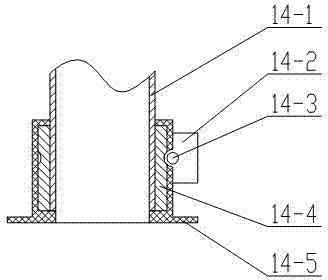

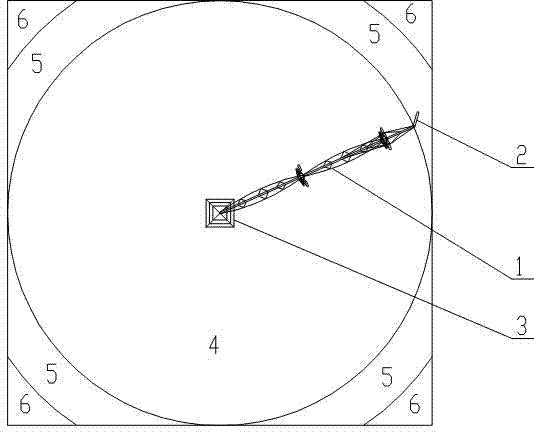

[0017] Such as figure 1 As shown, the present invention discloses a controllable variable spray gun, including a spray gun main body 2, a booster pump 7 and a spray gun connecting pipe 16; The water outlet of the booster pump 7 is connected to the water inlet of the spray gun body 2 through the spray gun connecting pipe 16; The outer side of the span body 1; the tail of the spray gun body 2 is installed on the end of the span body 1 of the central pivot irrigation machine through the horizontal rotation mechanism of the spray gun. The horizontal rotation of the spray gun main body 2 can be realized by the spray gun horizontal rotation mechanism. The water flow in the sprinkler pipeline 15 at the end of the sprinkler span body 1 is pressurized to the required pressure by the booster pump 7 to supply water to the spray gun main body 2 for the nozzle 12 to spray and irrigate. The afterbody of spray gun main body 2 is fixedly provided with spray gun variable section driving moto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com