Lubricating oil composition for transmission

A technology of lubricating oil composition and transmission, applied in the direction of lubricating composition, petroleum industry, etc., can solve the problem of sufficient research on the use of transmissions, achieve excellent anti-wear joint performance, and improve the effect of anti-wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

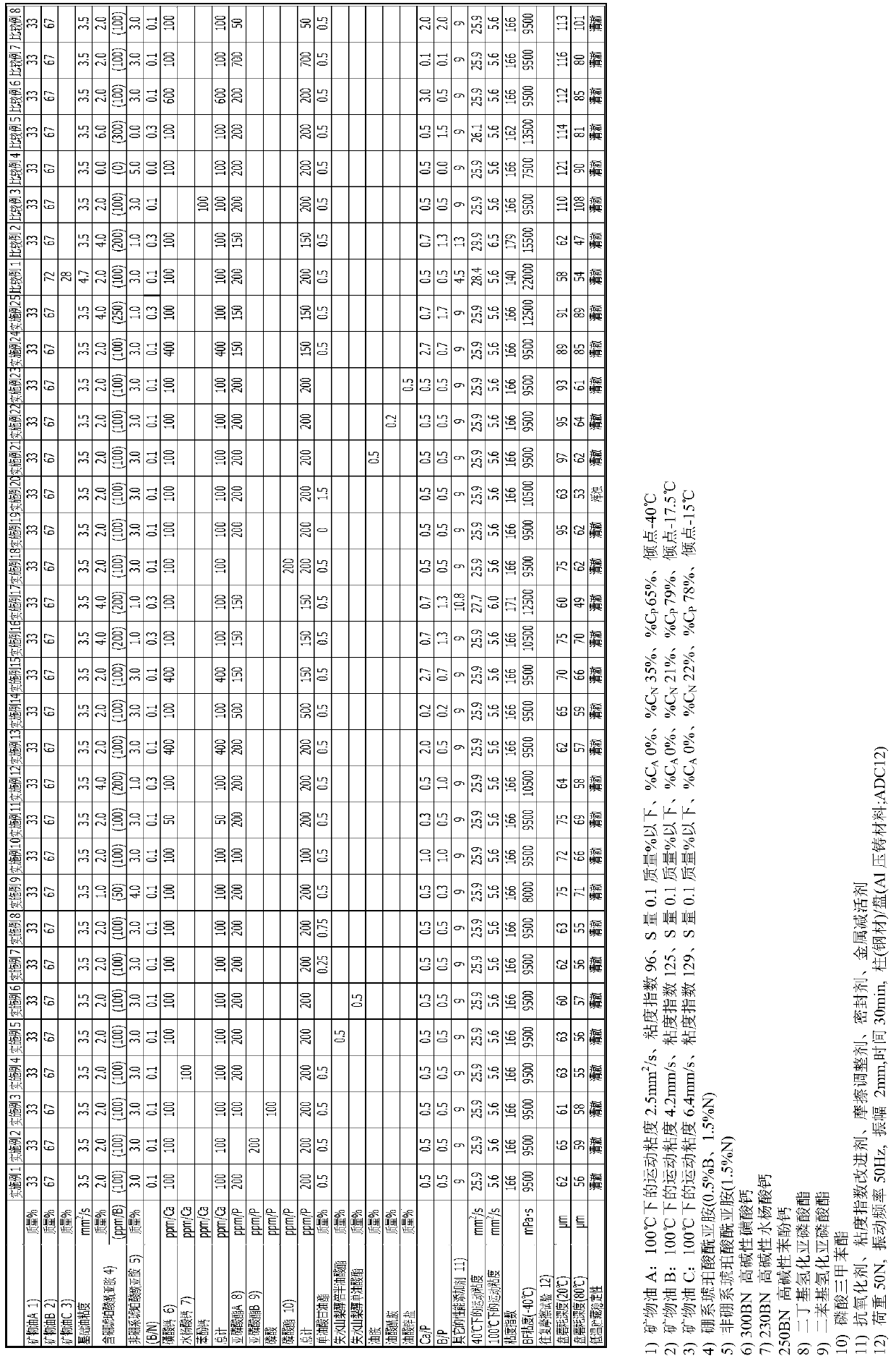

Embodiment 1~25 and comparative example 1~8

[0141] Each of the lubricating oil compositions shown in Examples 1 to 25 of Table 1 (made to have a kinematic viscosity of 5.3 mm at 100° C. 2 / s) and each lubricating oil composition shown in Comparative Examples 1 to 8 for comparison, the wear resistance of each aluminum alloy was evaluated, and the results are listed in Table 1 together. The proportion of the base oil is based on the total amount of the base oil, and the addition amount of each additive is based on the total amount of the composition.

[0142] The wear resistance was evaluated using an SRV tester manufactured by Optimol. The test conditions were set as load 50N, vibration frequency 50Hz, amplitude 2mm, time 30min, and oil temperature was evaluated at 20°C and 80°C. The material of the test piece is column (steel) / disk: (Al die-casting material; ADC12).

[0143] As shown by the results in Table 1, when using the compositions of Examples 1 to 25 described in the present invention, compared with Comparative...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com