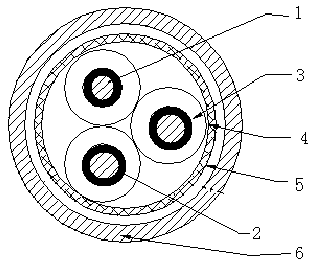

a power cable

A technology of power cables and conductors, applied to power cables with shielding layers/conductive layers, etc., can solve problems such as theoretical analysis of XLPE power cable failure causes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

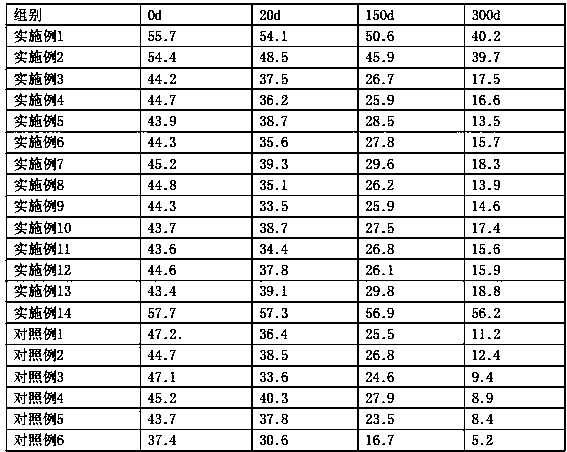

Examples

Embodiment 1

[0028] Example 1: Graphene is prepared, the mass ratio of nano-alumina is 20:7, 2g of graphene, 0.7g of nano-alumina. 18ml concentrated H 2 SO 4 , 8ml concentrated H 3 PO 4 , 20ml hydrogen peroxide solution, 100ml chloroform solution, 20g polyethylene, 300ml xylene.

[0029] Step 1, according to 9:4 18ml concentrated H 2 SO 4 and 8ml concentrated H 3 PO 4 , join in the there-necked flask that 2g graphene is housed;

[0030] Step 2, then add 20ml of hydrogen peroxide, and magnetic stirring at room temperature for 2h;

[0031] Step 3, then raise the temperature to 50°C, and magnetically stir for 3 hours under ultrasonic vibration treatment;

[0032] Step 4, then cooling to room temperature, adding 0.7g of nano-alumina, and magnetically stirring for 2 hours in an ice-water bath;

[0033] Step 5. After the ice-water bath treatment, perform centrifugation to remove the upper liquid, then repeatedly wash 5-6 times under hydrochloric acid and deionized water, and dry at 110...

Embodiment 2

[0039] Example 2: Graphene is prepared, the mass ratio of nano-alumina is 20:7.5, 2g of graphene, 0.75g of nano-alumina. 18ml concentrated H 2 SO 4 , 8ml concentrated H 3 PO 4 , 20ml hydrogen peroxide solution, 100ml chloroform solution, 20g polyethylene, 300ml dimethylbenzene, operating procedure is the same with embodiment 1.

Embodiment 3

[0040] Example 3: Graphene is prepared, the mass ratio of nano-alumina is 20:8, 2g of graphene, 0.8g of nano-alumina. 18ml concentrated H 2 SO 4 , 8ml concentrated H 3 PO 4 , 20ml hydrogen peroxide solution, 100ml chloroform solution, 20g polyethylene, 300ml dimethylbenzene, operating procedure is the same with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com