Turbine internal shut-off valve

A shut-off valve and turbine technology, applied in engine components, machines/engines, mechanical equipment, etc., can solve the problems of poor valve sealing, throttling loss in the gas flow process, and large valve volume, and achieve good sealing effect and response speed. quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention is described in more detail below in conjunction with accompanying drawing example:

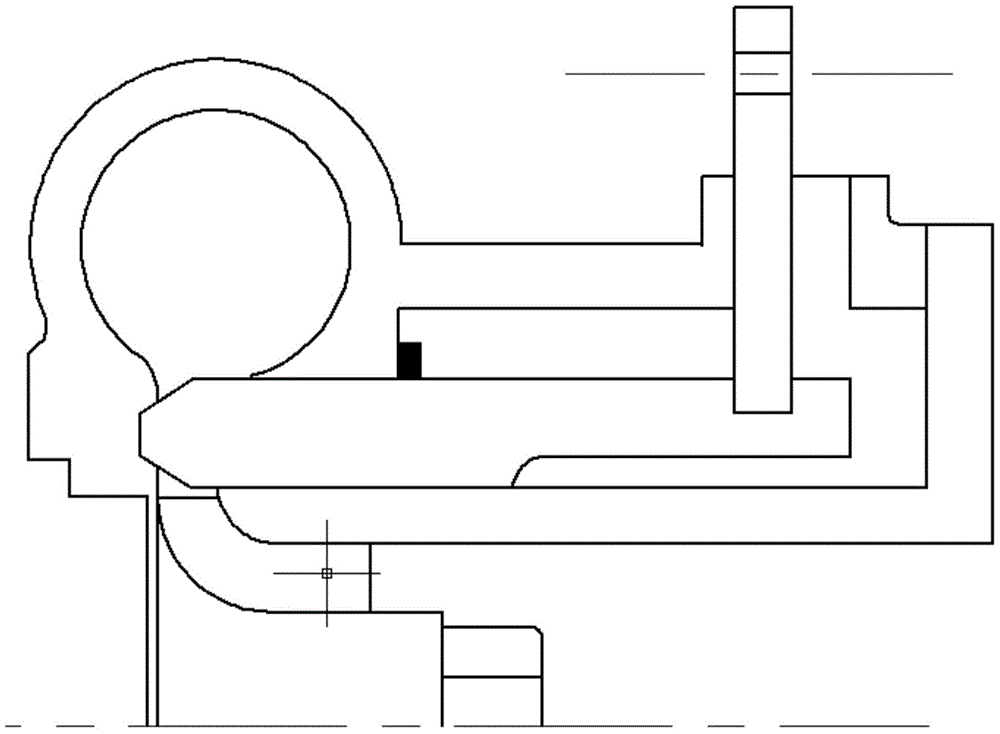

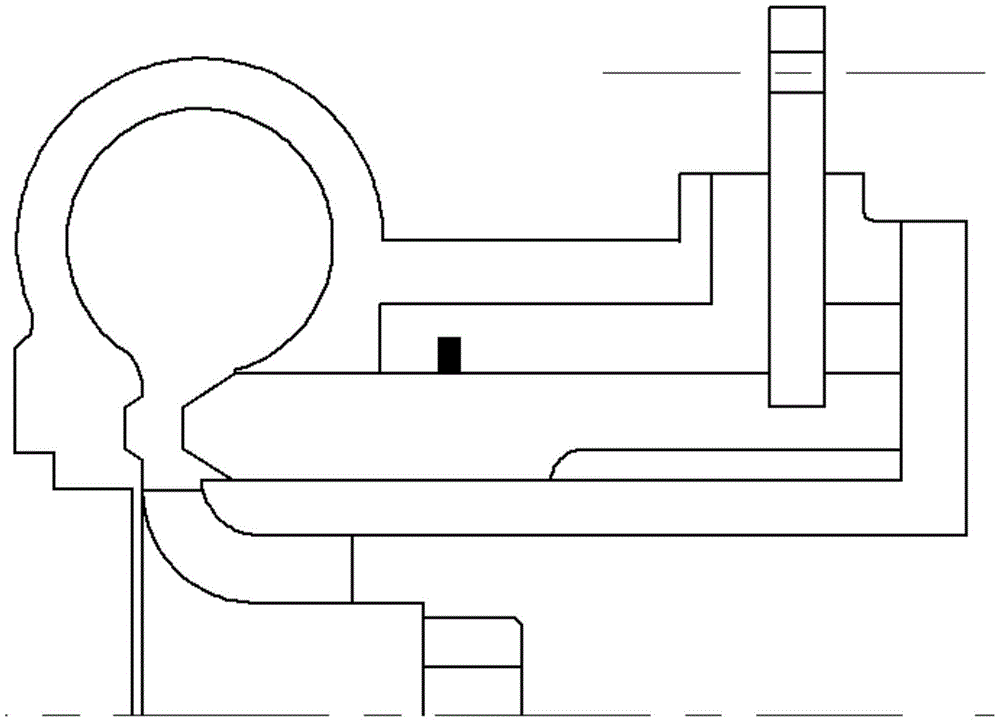

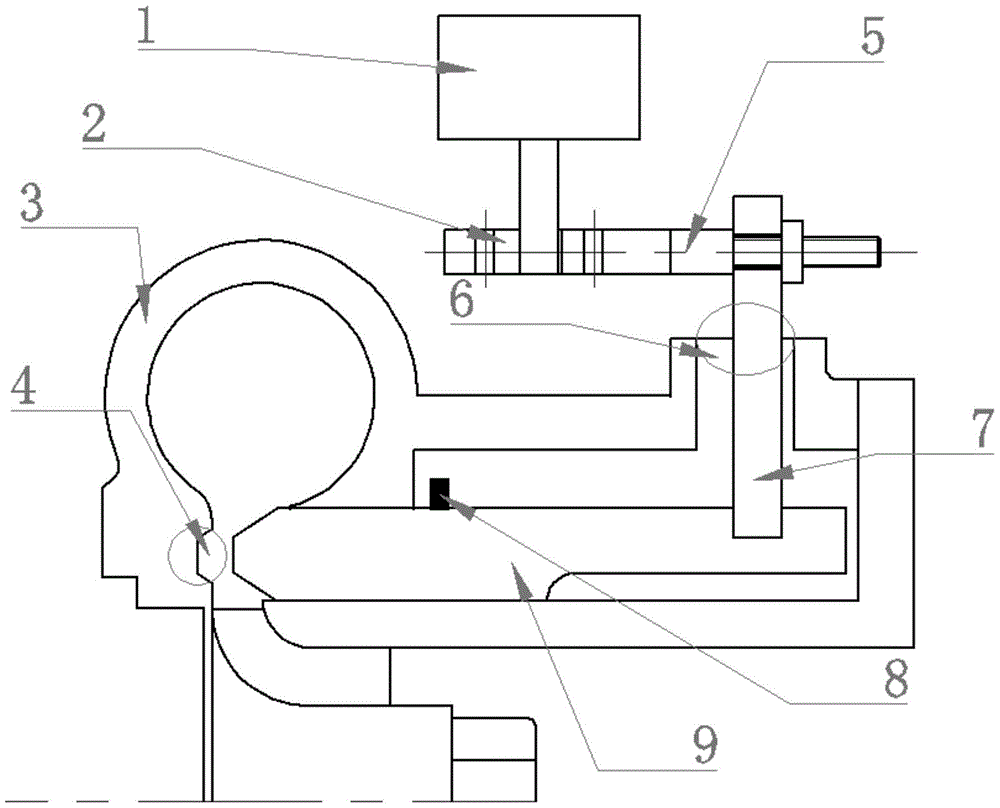

[0013] combine Figure 1~3 , figure 1 The valve is in the closed state. At this time, the trapezoidal structure at the left end of the valve is connected with the trapezoidal groove on the volute to realize the sealing effect. At this time, the exhaust gas cannot flow through the turbocharger to expand and do work, and the supercharger is in the cut-out state when it is not working. figure 2 The valve is fully open, the trapezoidal structure on the valve is completely out of the trapezoidal groove, the valve has moved to the far right, the supercharger cuts in, the exhaust gas flows through the turbocharger and expands to do work, and the supercharger starts to work. image 3 Is the valve is in the process of switching. The stepper motor 1 and the gear 2 are connected by a key, and the gear 2 cooperates with the rack at the left end of the driving rod 5 to conv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com